Use these 7 methods to identify TPE and TPU!

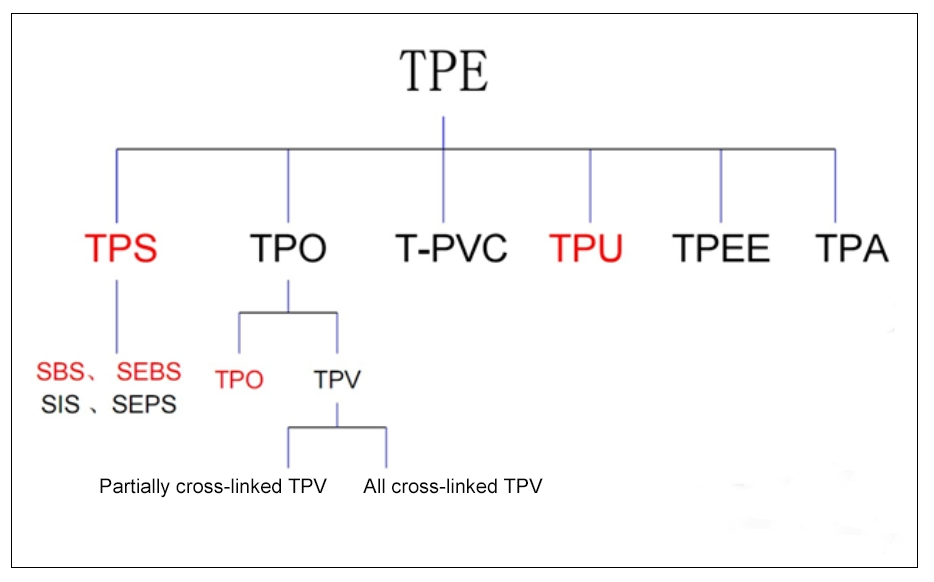

TPE is broadly speaking the general term for all thermoplastic elastomers. It is classified as follows:

But what is usually called TPE is a blend of SEBS/SBS+PP+naphthenic oil+calcium carbonate+auxiliaries. It is also called environmentally friendly soft plastic in the industry, but sometimes it is called TPR (it is more commonly called in Zhejiang and Taiwan) ). TPU, also called polyurethane, has two types: polyester type and polyether type.

TPE and TPU are both thermoplastic materials with rubber elasticity. TPE and TPU materials with similar hardness can sometimes be difficult to distinguish between TPE and TPU by just observing them with the naked eye. But starting with the details, we can still analyze the differences and differences between TPE and TPU from many aspects.

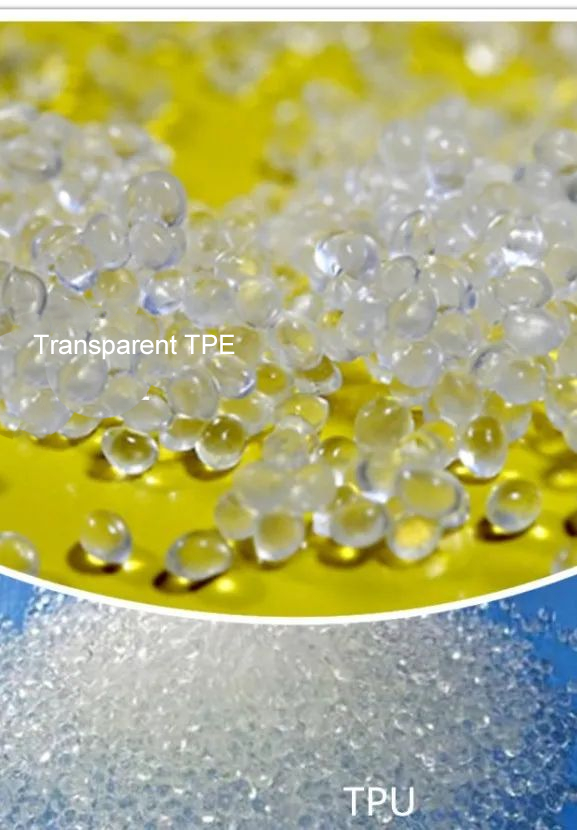

1.Transparency

The transparency of TPU is better than that of TPE, and it is not as easy to stick as transparent TPE.

2. Proportion

The proportion of TPE varies widely, ranging from 0.89 to 1.3, while TPU ranges from 1.0 to 1.4. In fact, during their use, they mainly appear in the form of blends, so the specific gravity changes greatly!

3.Oil resistance

TPU has good oil resistance, but it is difficult for TPE to be oil-resistant.

4.After burning

TPE has a light aromatic smell when burning, and the burning smoke is relatively small and light. TPU combustion has a certain pungent smell, and there is a slight explosion sound when burning.

5.Mechanical properties

TPU’s elasticity and elastic recovery properties (flexion resistance and creep resistance) are better than TPE.

The main reason is that the material structure of TPU is a polymer homogeneous structure and belongs to the polymer resin category. TPE is an alloy material with a multi-phase structure aggregated by a multi-component blend.

High-hardness TPE processing is prone to product deformation, while TPU shows excellent elasticity in all hardness ranges, and the product is not easy to deform.

6.Temperature resistance

TPE is -60 degrees Celsius ~ 105 degrees Celsius, TPU is -60 degrees Celsius ~ 80 degrees Celsius.

7.Appearance and feel

For some overmolded products, products made of TPU have a rough feel and strong friction resistance; while products made of TPE have a delicate and soft feel and weak friction performance.

To sum up, both TPE and TPU are soft materials and have good rubber elasticity. In comparison, TPE is more excellent in terms of tactile comfort, while TPU shows more excellent elasticity and strength.

Post time: Dec-05-2023