Spray Machine Selection Guide

With a wide variety of polyurethane spray machines available on the market today, producers are often overwhelmed by the multitude of options in terms of brands, shapes, and names of spray machines. This can lead to the selection of the wrong machine model. To facilitate producers in making the right choice, let’s discuss some methods for selecting spray machines.

1. Fully Understand the Types of Polyurethane Spray Machines:

Although the basic principle of spray machines is to introduce gas into the spray solution, different types of spray machines introduce gas in different ways. Knowing the type of spray machine will help understand its technical characteristics and usability, aiding producers in making an informed decision.

2. Thoroughly Grasp the Basic Technical Parameters of Polyurethane Spray Machines: For producers, it’s not enough to only understand the machine model and spraying principle. They also need to further understand several important technical parameters of spray machines to determine if they meet their production requirements.

- Output: Output refers to the foam production volume, which must be slightly higher than the required foam volume by about 20%, to leave room for flexibility. The lower limit of foam production volume should be the basis for calculation, rather than the upper limit.

- Installed Capacity: Installed capacity refers to the total power of the machine, which is essential for calculating the adaptability of electrical circuits to the total power consumption.

- Equipment Size: This parameter is a necessary factor for planning the overall layout of the workshop.

- Foam Diameter Range: Generally, it should be compared according to the specific product requirements for foam diameter.

3. Thoroughly Understand the Spraying Quality:

Judging the spraying quality of spray machines should primarily focus on three aspects: foam fineness, foam uniformity, and foam water emission.

- Foam fineness refers to the size of foam diameter. The smaller the foam diameter, the finer and denser the foam, resulting in better stability of the foam, higher product strength, and better insulation performance.

- Foam uniformity refers to the consistency of foam diameter, with a more uniform foam diameter indicating narrower distribution range and better stress distribution on the product, leading to better performance.

- Foam water emission refers to the amount of spray solution produced after foam rupture. The lower the foam water emission, the lower the foam water content, indicating better spraying performance.

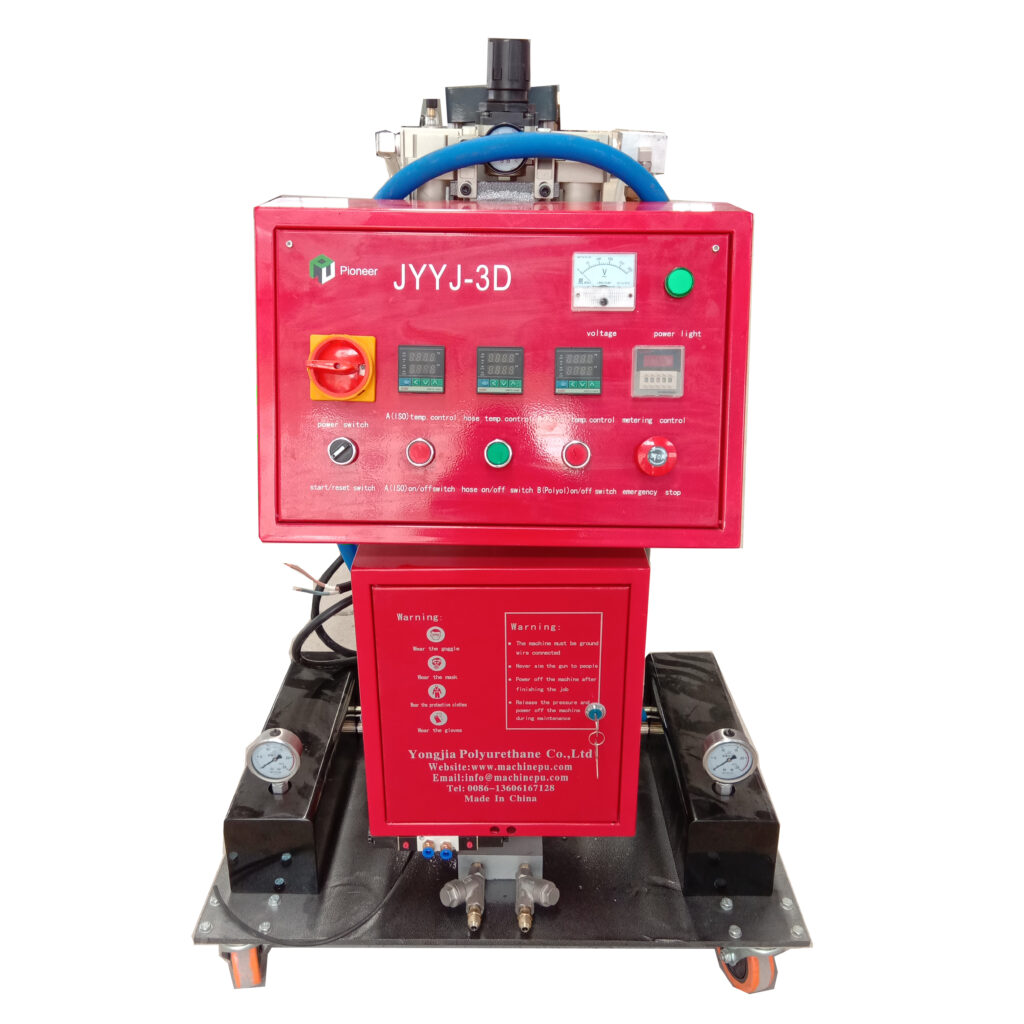

We are committed to producing high-quality high-pressure spray machines: polyurethane high-pressure spray machines, polyurethane spray machines, polyurethane spray equipment, polyurea spray machines, etc. These machines have the advantages of small size, low failure rate, simple operation, and easy mobility. They feature adjustable feeding quantity, timed and quantified functions, suitable for batch pouring, and can improve production efficiency. The multiple raw material filtration devices can effectively reduce clogging issues. New and old customers are welcome to visit our factory for inspection and machine trials.

Post time: Apr-10-2024