- The Commonality And Difference Between Polyurethane And Epoxy Resin:

The Commonality:

1) Polyurethane and epoxy resin are two-component, and the equipment and operation methods are basically the same;

2) Both have good tensile resistance, no cracking, no falling off and other properties;

3) Both have the properties of corrosion resistance to strong acid, alkali, salt and various oil substances;

4) Both have the properties of dustproof, waterproof, surface wear resistance, heavy pressure resistance, impact resistance and so on;

The Difference:

1) Polyurethane (PU) is polyphenylene diisocyanate and polyether polyol. It is cross-linked and cured in the presence of catalyst triethylene diamine to form high polymer. Compared with epoxy resin, it is more toxic.

Polyurethane has the characteristics of good adhesion, insulation and weather resistance. The hardness can be changed by adjusting the content of diisocyanate and polyether polyol, and it can be used in the packaging of various electronic and electrical equipment.

2) Epoxy resin is generally composed of bisphenol A epoxy resin, curing agent (amine or acid anhydride), auxiliary agent, filler, etc. It has a long curing time at room temperature and can be cured by heating. After curing, it has high bonding strength and hardness. Generally, it is relatively large and can be made transparent to encapsulate electrical modules and diodes.

Polyurethane has better weather resistance, does not crack at high and low temperatures, and is slightly more expensive.

2.the use of polyurethane and epoxy resin:

1) Polyurethane resin:

Polyurethane resin is a polymer material with high strength, tear resistance, wear resistance and other characteristics;

Used as rollers, conveyor belts, hoses, auto parts, shoe soles, synthetic leather, wires and cables and medical artificial organs, etc.;

For the manufacture of plastic products, wear-resistant synthetic rubber products, synthetic fibers, rigid and flexible foam products, adhesives and coatings, etc.;

It is used for surface finishing of various woodware, chemical equipment, telecommunication equipment and instruments and various means of transportation.

2) Epoxy resin: can also be used in coatings, adhesives, composite materials, etc.

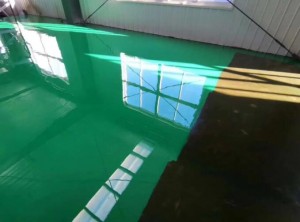

Epoxy resin coating is a kind of high-strength, wear-resistant and beautiful floor, which has the advantages of seamless, solid texture, good chemical resistance, anti-corrosion, dust-proof, convenient maintenance and low maintenance cost.

Various schemes can be designed according to customer requirements, such as thin-layer coating, 1-5mm thick self-leveling floor, anti-skid and wear-resistant floor, mortar floor, anti-static, anti-corrosion floor, etc.

Products are suitable for various venues, such as workshops, computer rooms, warehouses, laboratories, wards, operating rooms, workshops, etc.

3. The former topcoat is suitable for outdoor use, while the latter is suitable for indoor use;

The biggest weakness or disadvantage of the latter is that it is afraid of strong ultraviolet radiation, and it will turn yellow under strong ultraviolet radiation, that is, fade, but it will not decompose and will not affect the use;

However, the former is much improved in weather resistance than the latter, especially the yellowing time of the former is much longer than that of the latter, so the former is often used for outdoor construction requirements.

Post time: Jun-17-2022