100% Original Freezer Making Machine - Polyurethane Memory Foam Insoles Plantar Fasciitis Arch Support Insoles Injection Moulding Machine – Polyurethane

100% Original Freezer Making Machine - Polyurethane Memory Foam Insoles Plantar Fasciitis Arch Support Insoles Injection Moulding Machine – Polyurethane Detail:

Polyurethane Memory Foam Insoles Plantar Fasciitis Arch Support Insoles Injection Moulding Machine

Introduction:

Polyurethane Insoles are designed for those who lead a highly active lifestyle, especially for people involved with sporting activities. … Rather than just absorbing the shock, polyurethane has the ability to turn this energy around and use it to increase and enhance performance rather than just absorbing it.

| Bucket | Metering Pump | Metering Pump Motor Power | Spit Out Quality | Total Power |

| A.120L | JR9 | 0.75kw | 10-40g/s | 8.5kw |

| B.120L | JR3.6 | 0.55kw | ||

| S.2L | JR0.3 | 0.2kw |

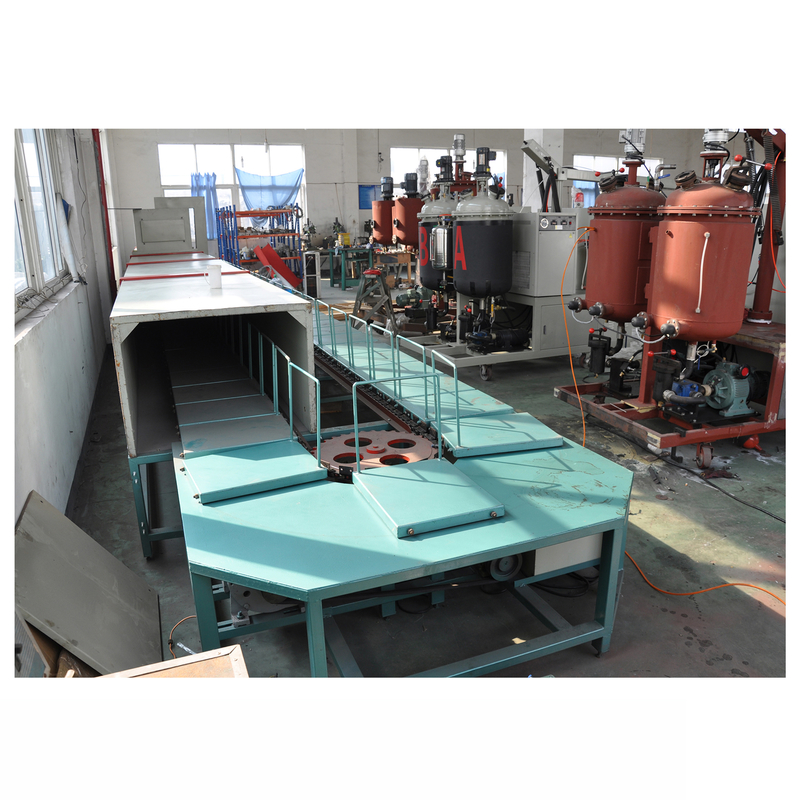

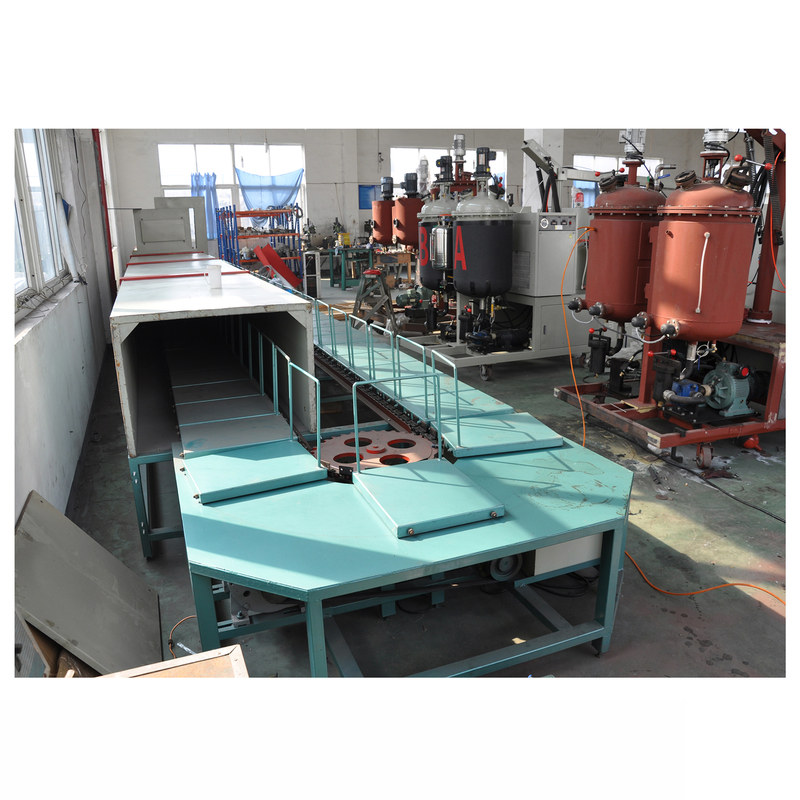

Technical parameters of pu shoe production line:

1. Annular line length 19000, drive motor power 3 kw/GP, frequency control;

2. Station 60;

3. Oven length 14000, heating power 28kw, inner motor power 7 * 1.5 kw;

4. Mold opening and clamping adopt servo motor 1.5kw,, reducer PF – 115-32;

5. The panasonic PLC control, 10 inch touch screen;

6. Manufacturing process: injection mold release – hand set pieces – clamping – open die – casting mould – the – - cure – lock -molding – artificial pick-up – clean up moldHost equipment of pu shoe production line:

Product component:

Material system consists of material tank, filtering tank, metering pump, material pipe, infusion head, cleaning tank.

1.Material Tank:

Double interlining heating material tank with insulation outer layer, heart rapidly, low energy consumption. Liner, upper and low head all use stainless 304 material, upper head is precision machinery sealing equipped to make sure the air tight agitation.

2. Filter tank

Material in the tank flow to the filter tank Φ100X200 by discharge valve, after filtering, flow to the metering pump. Sealing flat cover on the tank, inner tank with a filter net, tank body with a feeding and discharge port, there is a discharge ball valve below the tank.

Application:

It is designed as everyday use comfort insoles for men and women. It is ideal for use in standing, walking, running, cross training, climbing, hiking, as well as casual occasions. It fits better in roomy or high-profile footwear.

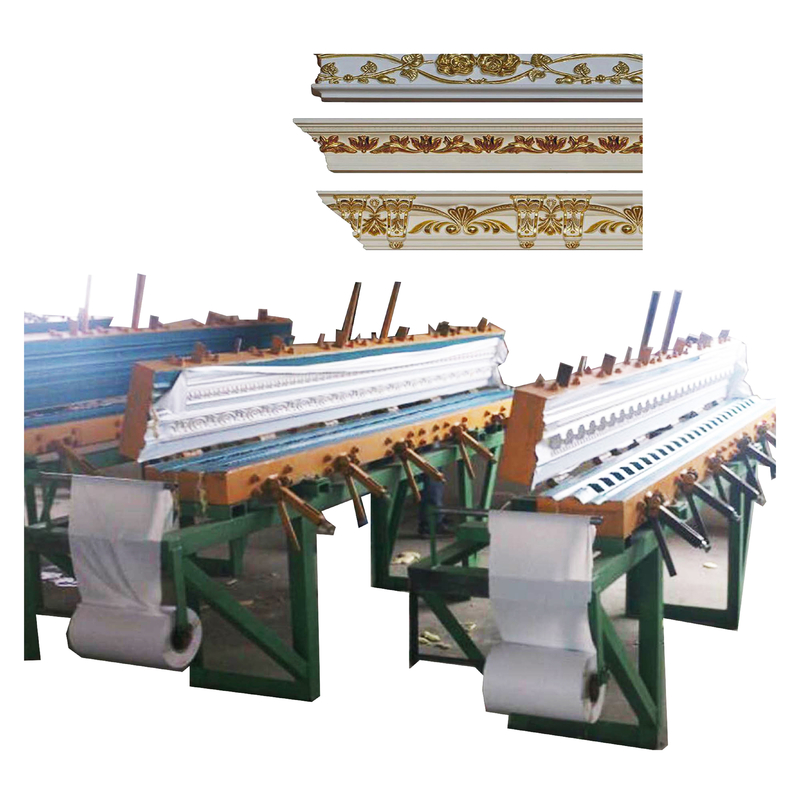

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of 100% Original Freezer Making Machine - Polyurethane Memory Foam Insoles Plantar Fasciitis Arch Support Insoles Injection Moulding Machine – Polyurethane, The product will supply to all over the world, such as: Malta, Kazakhstan, Oman, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.