2022 New Style 3d Wall Panel - PIR Fireproof Insulated Cold Room Panel Machine PU Sandwich Panel Production Line – Polyurethane

2022 New Style 3d Wall Panel - PIR Fireproof Insulated Cold Room Panel Machine PU Sandwich Panel Production Line – Polyurethane Detail:

| High Light: |

Cold Room pu sandwich panel machine, PIR pu sandwich panel machine, Fireproof polyurethane sandwich panel machine |

||

|---|---|---|---|

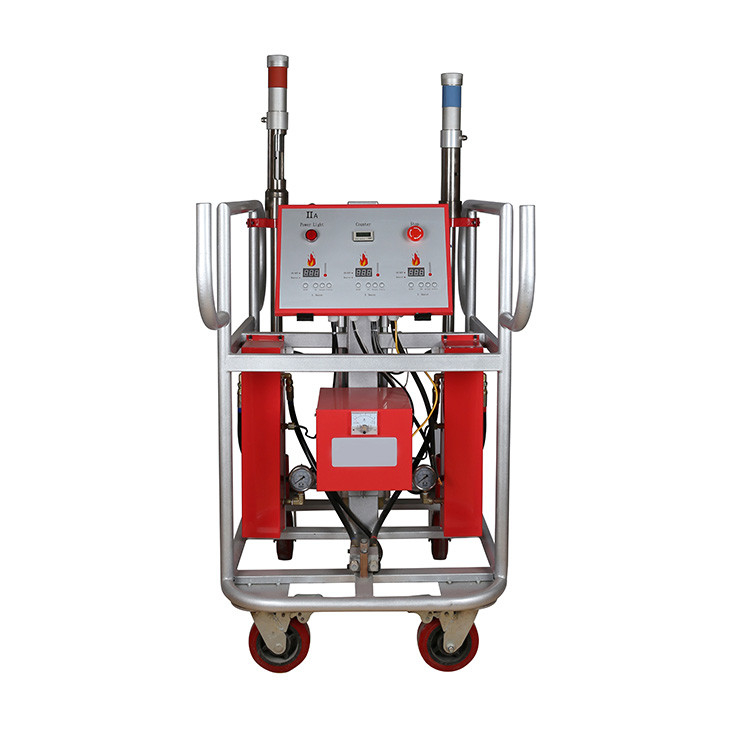

PIR Fireproof And Insulated Cold Room Panel Machine PU Sandwich Panel Production Line Introduction of polyurethane sandwich panel production line: Polyurethane composite board continuous production line is composed of machine,electricity, liquid & polyurethane, it’s automatic continuous production line composed of many units. The production line adopts the international advanced technology of roll forming (chemical) and polyurethane foaming technology, composite technology and hydraulic transmission technology, control technology numerical control, automatic stacking technology. Main Parameters Of Production Line:

| Production Plate Specification 1) Roof and wall panel: required as the plate type diagram. Width: 1000mm Thickness: 40-200mm (corrugation is not included) Length : minimum cutting length 3m (manual cutting is not included) 2) Material Specification: Steel thickness : 0.4-0.8 mm (Steel is smoothsdistortionless) Steel maximum width : 1250mm (Size Precision: ±2mm) Steel Strength : 235 MPa Coil maximum weight : 5 T Coin inner diameter : φ508,φ610mm 3) Production line specification : Speed of production line : 3-10 m/min (adjustable) The total length of production line : about 160 meters Working table height : 1200mm Working pressure of foam pouring : 150-200 bar The length of double-belt conveyor : 24 m Control way: PLC controlling Total Power: about 250kw (heating power is not included) Power Supply : 380V/3 phases/50Hz Control Voltage: 24V/110V/220V ; Pneumatic:0.7Mpa (factory brings along with their own) |

Technical parameters:

1) Every uncoiler includes coiling block, machine base and drive system, it adopts hydraulic cantilever expanding and has manual centering device:2) Type of coil:painted steel coil, aluminum coil:3) Thickness of steel sheet:0.4-0.8 mm:4) Inner diameter of steel coil:φ508mmsφ610mm:5) Outer diameter of steel coil:φ1800mm:6) Weight capacity of steel coil:5T:7) Width of steel coil:Max 1250mm: Centre adjustment: Max 150mm8) With material pressing device:it is fixed at 30-40°above,which can avoid the loosing of steel coil during uncoiling:Lifting table(1 pc):hydraulic motor drives lifting table move along the guide Traveling Speed : 6 m/minLifting route: Max 350mm; Cross travel:Max 3000mm9) Pneumatic hydraulic system Max hydraulic pressure: 16 MPa;Hydraulic station Motor Power: 7.5kw Pneumatic:0.7Mpa (factory brings along with their own)

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for 2022 New Style 3d Wall Panel - PIR Fireproof Insulated Cold Room Panel Machine PU Sandwich Panel Production Line – Polyurethane, The product will supply to all over the world, such as: Belarus, Roman, Florence, With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.