Best Price for Injection Molding Machine For Air Filters - Nonwoven PU Artificial Leather Substrate Coating Production Line Polyurethane Casting Machine – Polyurethane

Best Price for Injection Molding Machine For Air Filters - Nonwoven PU Artificial Leather Substrate Coating Production Line Polyurethane Casting Machine – Polyurethane Detail:

| Product Name: | Pu Leather Machine Line | Applicable Fabric: | Linen Fabric |

|---|---|---|---|

| Unwinding Diameter: | 1600mm | Raw Material: | Polyol+Isocyanate |

| High Light: |

Artificial Leather Polyurethane Casting Machine, Nonwoven Polyurethane Casting Machine, Nonwoven pu casting machine |

||

Nonwoven PU Artificial Leather Substrate Coating Production Line Polyurethane Casting Machine Introduction:This machine is mainly used for the composite processing of polyurethane soft foam, sponge and various fabrics, non-woven fabrics, etc. The sponge that needs to be processed is melted by flame high temperature and then pressed with the required fabric, and then water-cooled and shaped. Then the automatic rolling is the composite product.

| Effective coating width | 600-1600mm |

| Production speed | 2-20m/min(Depends on production technology) |

| Unwinding diameter | ≤Φ600mm |

| Reminding diameter | ≤Φ600mm |

| Drying type | Electric heating cycling wind |

| Temperature control | 60-400°C±2°C |

| Winding edge planeness | ±2mm |

| Total power | About 265kw(including electric heating power about 18kw*13=234kw) |

| Overall dimension | 18000*2500*7000mm(L*W*H) |

| Coating type | glue-soaking coating (one side coating is achievable) |

Features: 1. The composite material has the advantages of uniform coating, compound flatness, no tensile deformation, no foaming, no wrinkle, good hand feeling, softness, good gas permeability and neat winding.2. There are many varieties of composite materials, especially suitable for coating and compounding of cloth, non-woven cloth, cloth leather, sponge and flannel, sponge and leather;3. Receiving and unwinding can choose the appropriate configuration according to different materials;4. According to the characteristics of different materials, some devices can be added or removed;5, suitable for water-soluble and solvent-based adhesive coating and composite, to achieve a multi-purpose function.6. The amount of glue applied and the type of glue applied can be adjusted according to the material and actual needs.7. The drum heating can be performed by means of electricity, steam or heat transfer oil.8. The width of the machine roll surface can be specified according to the width of the actual material.9, the winding can be used for surface winding, center winding or large package.10. The whole system can be operated by intelligent PLC program touch screen or mechanical type. Application: Mainly used in apparel fabrics, fleece, non-falling, elastic fabrics, non-woven fabrics, pongee, denim, milk silk, TC fabrics, woolen, silk, plush, leather, sponge, woven fabrics, etc. The combination between the two, widely used in clothing, automotive interiors, shoes and hats, luggage, decoration, home textiles, toys and other industries.

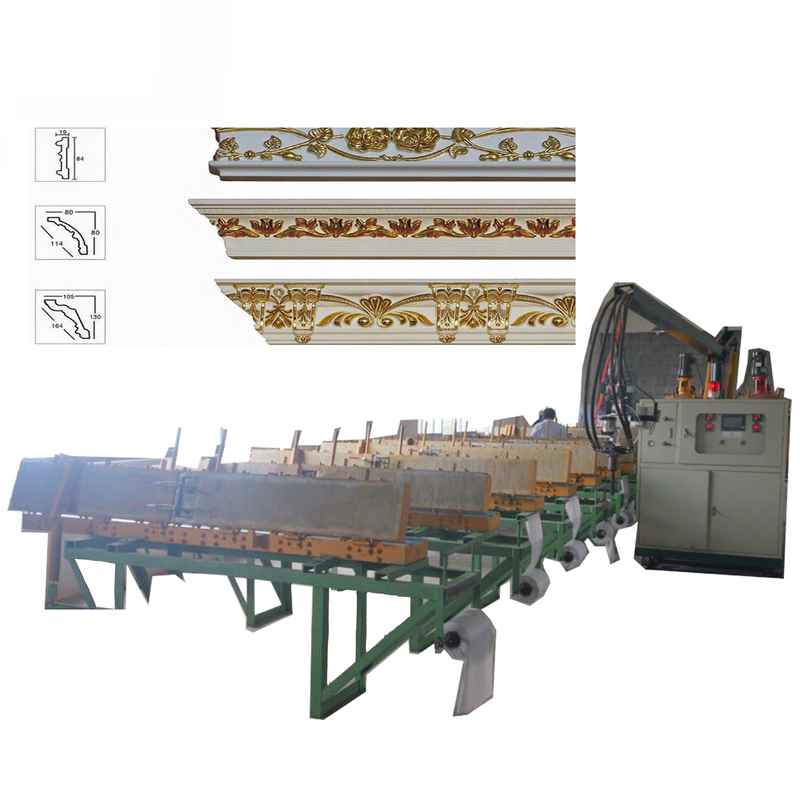

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for Best Price for Injection Molding Machine For Air Filters - Nonwoven PU Artificial Leather Substrate Coating Production Line Polyurethane Casting Machine – Polyurethane, The product will supply to all over the world, such as: Puerto Rico, Georgia, Moldova, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!