Best-Selling Molded Foam Chair - Low Temperature Resistance Car Baby Seat ODM PU Foam Mould – Polyurethane

Best-Selling Molded Foam Chair - Low Temperature Resistance Car Baby Seat ODM PU Foam Mould – Polyurethane Detail:

| Material: | Aluminum | Life Time: | More Than 10 Years |

|---|---|---|---|

| OEM&ODM: | Available | Fast Prototype: | Available |

| Name: | PU Foam Mould | Product: | Car Baby Seat |

| High Light: |

Alu polyurethane mold, Alu PU Foam Mould, ODM PU foam mould |

||

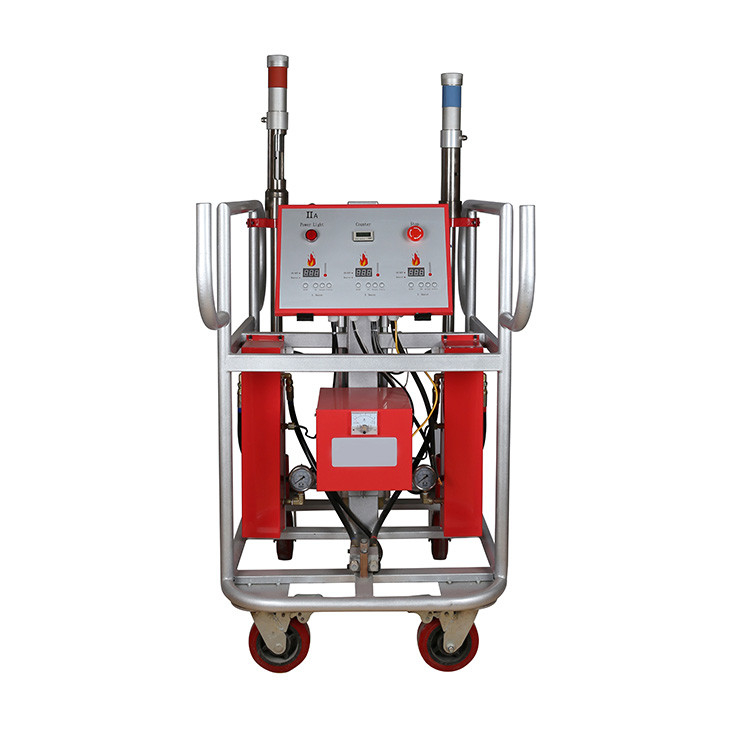

Low-temperature Resistance pu Polyurethane Mold For Car baby Seat blow Molding MouldOur car seat Injection Mold Mould advantange:

1) ISO9001 TS16949 and ISO14001 enterprise, ERP management system

2) Engaged in precision plastic mold manufacturing for more than 16 years, accumulated rich experience

3) Stable technical team and frequent training system. Middle managers have worked in the store for more than 10 years

4) Advanced processing equipment, Swedish CNC center, mirror EDM and Japanese precision wire cutting our professional one-stop plastic mold customization service:

1) Provide customers with automotive seat injection mold design services and image design

2) Injection mold manufacturing, two injection mold, gas auxiliary mold

3) Precision plastic molding: secondary injection molding, precision plastic molding and gas assisted molding

4) Plastic Secondary operation,like Silk-screeking,UV,PU painting,Hot stamping,Laser engraving,Ultrasonic welding,Plating etc.

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production |

| Certificate | ISO 9001:2008 |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PU |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

Product ApplicationsOur molds can be widely used to make car seat cushions, backrests, child seats, sofa cushions for daily use seats, etc.

Our company advantages

It is a company specializing in the production of aluminum alloy precision casting mold manufacturers, the main production of PU foam plastic mold, all kinds of polyurethane foam plastic toy mould and rubber elastic ball bubble plastic mould, including PU high resilience foam plastic moulds, car seat cushion, the armrest die mold, car steering wheel, peeled, and memory foam pillow molding foam aluminum mold, etc., And according to customer drawings and sample requirements

.

.

Product detail pictures:

Related Product Guide:

The business keeps to the operation concept "scientific management, premium quality and efficiency primacy, customer supreme for Best-Selling Molded Foam Chair - Low Temperature Resistance Car Baby Seat ODM PU Foam Mould – Polyurethane, The product will supply to all over the world, such as: Palestine, Seychelles, Turkey, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.