Big Discount Spray Foam Machine Cost - Polyurethane PU Foam 14*28 cm Bricklayer Trowel Plastering Float Making Machine – Polyurethane

Big Discount Spray Foam Machine Cost - Polyurethane PU Foam 14*28 cm Bricklayer Trowel Plastering Float Making Machine – Polyurethane Detail:

Polyurethane PU Foam 14*28 Bricklayer Trowel Plastering Float Making Machine

Polyurethane is a critical component of many industries and impacts the performance of multiple products in consumer, business, and government applications. Every day, our metering systems are put to the test in these applications — and only the best pass. That’s because in many industries, it’s about more than just performance and accuracy — it’s about protecting people, ensuring safety, and promoting health and wellness. That’s why we customize all of our polyurethane processing equipment to help our clients meet these strict demands.

Product Description of our polyurethane foam dispensing machine:

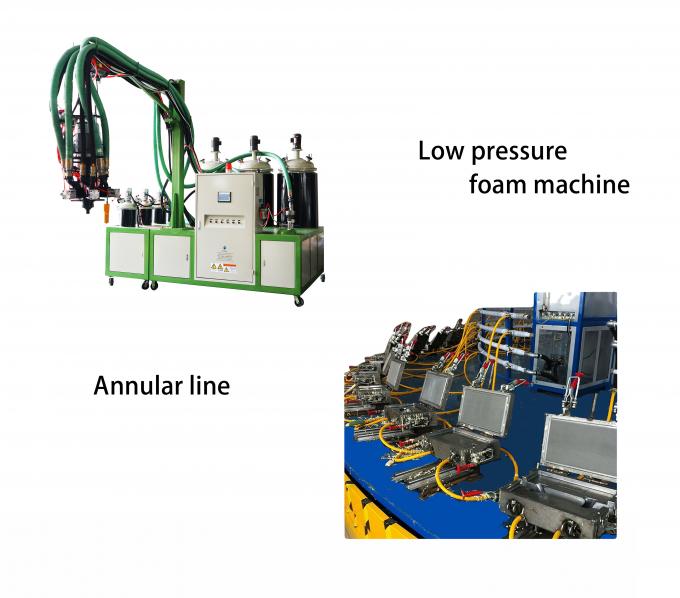

We are proud to offer best-in-class polyurethane processing equipment. Our high-pressure or low-pressure metering systems provide immense flexibility to support your polyurethane processing and dispensing needs.

| No | Item | Technical parameter |

| 1 | Foam application | Rigid foam |

| 2 | raw material viscosity(22℃) | Polyol~3000CPS ISO ~1000MPas |

| 3 | Injection output | 16-65g/s |

| 4 | Mixing ration range | 100:50~150 |

| 5 | mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank volume | 120L |

| 7 | metering pump | A pump: JR12 Type B Pump: JR12 Type |

| 8 | compressed air needed | dry, oil free, P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

| 9 | Nitrogen requirement | P:0.05MPa Q:600NL/min(Customer-owned) |

| 10 | Temperature control system | heat:2×3.2Kw |

| 11 | input power | three-phase five-wire 380V 50HZ |

| 12 | Rated power | About 9KW |

| 13 | swing arm | Rotatable swing arm, stretch out 2.3m(length customizable) |

| 14 | volume | 4100(L)*1250(W)*2300(H)mm, swing arm included |

| 15 | Color( customizable) | Cream-colored/orange/deep sea blue |

| 16 | Weight | 1000Kg |

Features of polyurethane foam making machine:

- Output ranging from 100 to 6000 g/min to meet your production needs

- Features an optional third component module for expanded capabilities

- Tank sizes available from 9 to 264 gallons (34 to 1000 liters)

- Also features degassing, a service modem, and volumetric mass flow control

- Automatic refilling ensures continuous material flow

- Supported by a best-in-class warranty and repair program

Our professional one-stop project solution service:

“Turnkey” Automated systems

Custom Foaming chemicals

Application of plastic pu trowels:

Application of plastic pu trowels:

A trowel is a small hand tool used for digging, applying, smoothing, or moving small amounts of viscous or particulate material.

Our Team:

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Product detail pictures:

Related Product Guide:

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for Big Discount Spray Foam Machine Cost - Polyurethane PU Foam 14*28 cm Bricklayer Trowel Plastering Float Making Machine – Polyurethane, The product will supply to all over the world, such as: Norway, Lesotho, Ukraine, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.