Bottom price Foam For Foam Machine - Flexible Polyurethane Foam Neck Support Rest Pillow Making Ring Production Line – Polyurethane

Bottom price Foam For Foam Machine - Flexible Polyurethane Foam Neck Support Rest Pillow Making Ring Production Line – Polyurethane Detail:

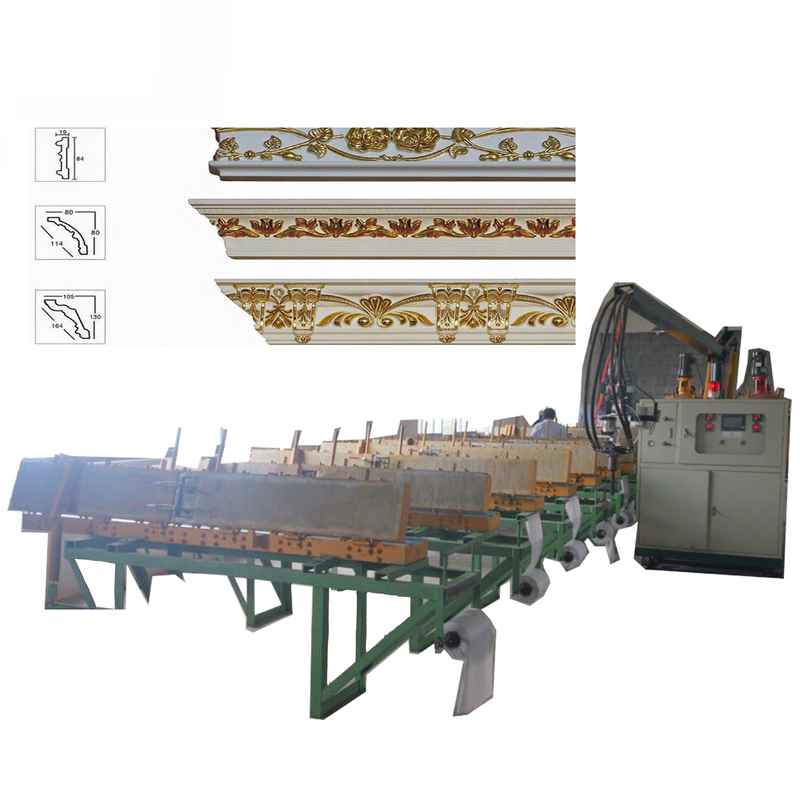

Flexible Polyurethane Foam Neck Support Rest Pillow Making Ring Production Line

Product Description:

The disc line is used for foaming production of all kinds of polyurethane products. The equipment runs at constant speed, and the running speed and production rhythm can be adjusted. The disk is equipped with a power supply and gas source conveying system. It forms a complete foaming production line with mould temperature machine.

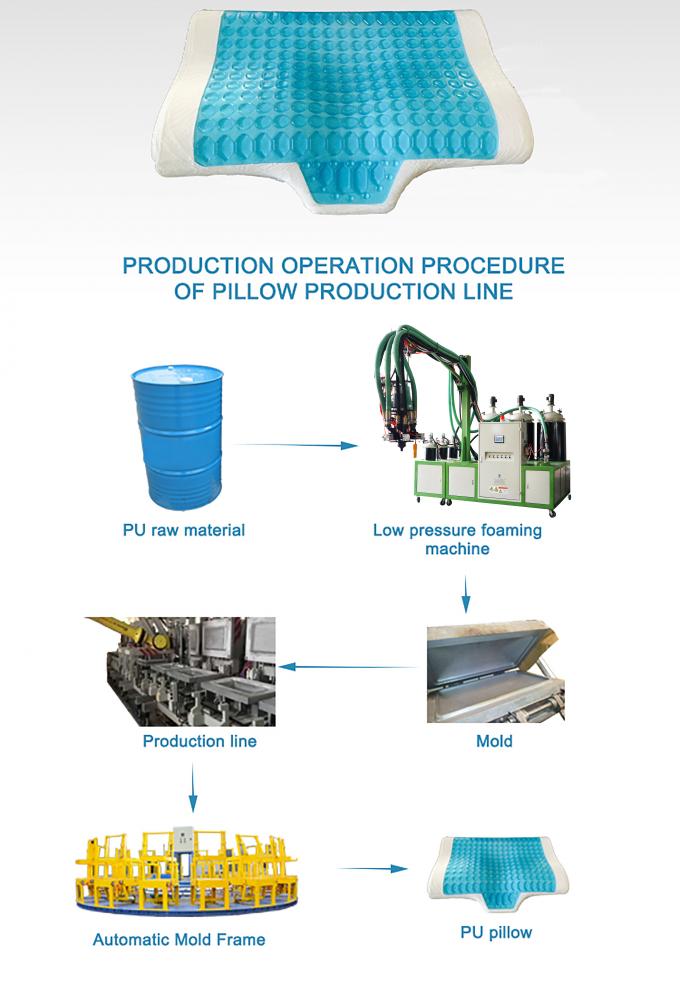

Pillow production line can be divided into three parts: 1.low or high pressure foam machine, 2.pillow production line, 3.pillow mold.

The equipment is composed of rotary platform, gas and electricity rotation device, pipeline device, transmission device, mold frame installation floor and electrical part, etc.

The turntable is equipped with a mold temperature machine. Mold temperature machine is a 80L water tank, a set of 48kw heating device, a circulating pump and a control cabinet. It is through the pump cycle to provide hot water to the mold, thus controlling the mold temperature.

Low-pressure polyurethane foam machines support a number of applications in which lower volumes, higher viscosities, or differing levels of viscosity between the various chemicals used in a mixture are required. To that point, low-pressure polyurethane foam machines are also an ideal choice when multiple streams of chemicals need to be treated differently prior to mixture.

| Low pressure foam machine technical Parameter | |

| Injection output | 2-1000g/s |

| Material tank volume | 30L-120L |

| Mixing ratio range | 100:28~48 |

| Mixing head | 2800-5000rpm, forced dynamic mixing |

| Compressed air needed | dry, oil free, P:0.6-0.8MPa Q:600NL/min(customer-owned) |

| Nitrogen requirement | P:0.05MPa Q:600NL/min(customer-owned) |

| Temperature control system | heat:2×3KW |

| Input power | 380V 50HZ |

| Rated power | 8KW-12KW |

| Weight | 600Kg-1200Kg |

| Dimension | 4100(L)*1250(W)*2300(H)mm |

Memory Foam Pillow Making Process:

More benefits of this ventilated contour memory foam pillow:

1.CertiPUR-US Certified Memory Foam. Quality material maintains its shape and performance for years.

2. Skin-friendly, easy-care, and machine washable pillow cover STANDARD 100 by OEKO-TEX certificated.

3. Natural firm support with ergonomic design.

4. Cooling holes ventilated design. Say goodbye to night sweats

5. Relieve shoulder and back stiffness. Refreshed the next morning when waking up.

6. Two heights are optional for side, back, and stomach sleepers. There is always one for you.

7. Perfect gift for your loved people. A thoughtful and delightful present was assured.

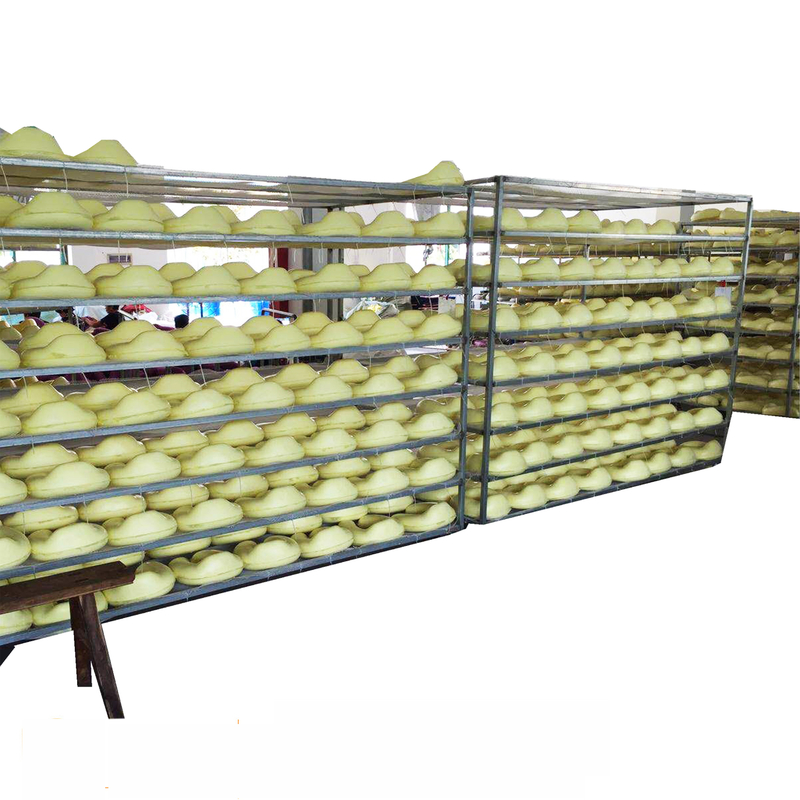

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for Bottom price Foam For Foam Machine - Flexible Polyurethane Foam Neck Support Rest Pillow Making Ring Production Line – Polyurethane, The product will supply to all over the world, such as: Costa Rica, Paris, Ethiopia, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!