Factory best selling Injection Plastique Machine - Car Seat Making 80g/s Low Pressure PU Foaming Machine – Polyurethane

Factory best selling Injection Plastique Machine - Car Seat Making 80g/s Low Pressure PU Foaming Machine – Polyurethane Detail:

| Machine Type: | Injection Machine | Condition: | New |

|---|---|---|---|

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Product Type: | Foam Net |

| Voltage: | 380V | Power (kW): | 168kW |

| Weight (KG): | 1200 KG | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Showroom Location: | Turkey, Pakistan, India |

| Applicable Industries: | Manufacturing Plant | Name: | Injection Foam Equipment |

| Filter: | Self-cleaning Filter | Material Feeding: | Automatic Feeding System |

| Control System: | PLC | Metering Pump: | Precise Metering |

| Tank Volume: | 250L | Power: | Three-phase Five-wire 380V |

| Port: | Ningbo | ||

| High Light: |

168kW Low Pressure PU Foaming Machine, 80g/s Low Pressure PU Foaming Machine, 5000rpm Polyurethane Foam Machine |

||

New Design Polyurethane Foam Machine For Car Seat Making Product Description: Polyurethane low-pressure foaming machine is widely used in multi-mode continuous production of rigid and semi-rigid polyurethane products, such as: petrochemical equipment, directly buried pipelines, cold storage, water tanks, meters and other thermal insulation and sound insulation equipment craft products.

| No. | Item | Technical parameter |

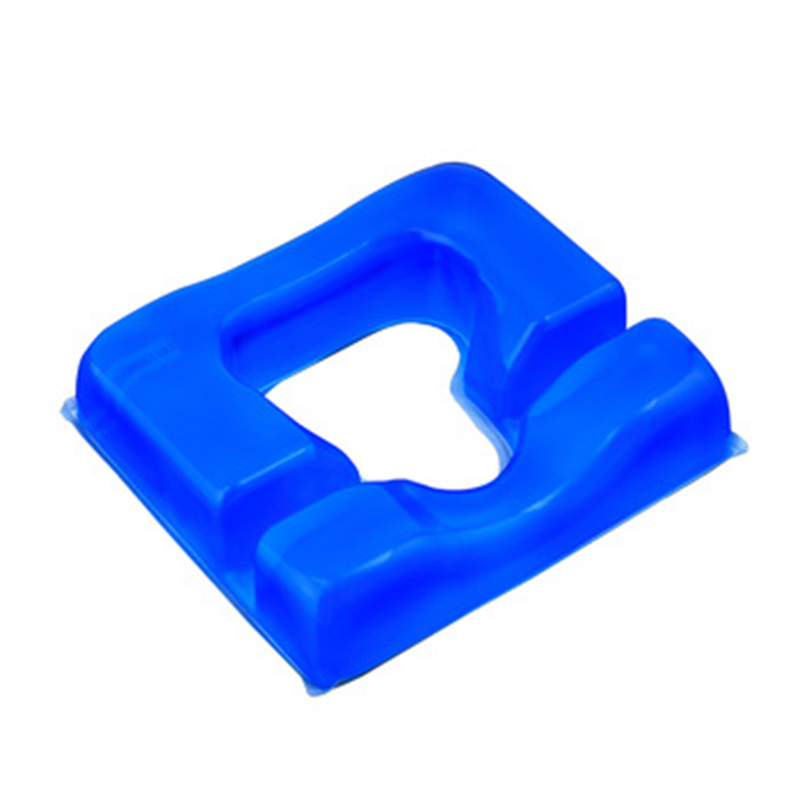

| 1 | Foam application | Flexible Foam Seat Cushion |

| 2 | Raw material viscosity(22℃) | POL ~3000CPS ISO ~1000MPas |

| 3 | Injection flow rate | 80-450g/s |

| 4 | Mixing ratio range | 100:28~48 |

| 5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank Volume | 120L |

| 7 | Input power | Three-phase five-wire 380V 50HZ |

| 8 | Rated power | About 11KW |

| 9 | Swing arm | Rotatable 90°swing arm, 2.3m (length customizable) |

| 10 | Volume | 4100(L)*1300(W)*2300(H)mm, swing arm included |

| 11 | Color( customizable) | Cream-colored/orange/deep sea blue |

| 12 | Weight | About 1000Kg |

Features of Low Pressure Foam Machine:Features of low-pressure cotton soaking machine: accurate measurement: high-precision low-speed gear pump, error ≤ 0.5%.

2. Uniform mixing: multi tooth high shear mixing head is adopted, with reliable performance.

3. Pouring head: special mechanical seal is adopted to prevent air leakage and pouring.

4. Stable material temperature: the material tank adopts its own heating temperature control system, the temperature control is determined, and the error is ≤ 2 ℃

5. The whole machine adopts 7-inch touch screen, PLC module control, regular and quantitative pouring, air volume flushing and automatic cleaning.

Raw material formulation solution support:

We have our own technical team of chemical engineers and process engineers, all of whom have more than 20 years of PU industry experience. We can independently develop raw material formulas such as polyurethane hard foam, Pu soft foam, polyurethane integral skin foam and polyurea to meet the needs of all customers. Application:

FAQ:

1. Are you a factory or a trading company?

We are a professional manufacturer with more than ten years of experience in PU industry. Our products include high-pressure pouring machine, low-pressure foaming machine, polyurethane spraying foaming machine, polyurethane elastomer casting machine and production line.

2. Where is your factory?

Our factory is located in Wuxi City, Jiangsu Province.

3. How can I get to your factory?

Aviation: fly from China to Wuxi airport, and fly directly to Wuxi from South Korea, Japan, the United States, Singapore, Taiwan and Thailand.

By train: you can stop at Wuxi station, not Wuxi East Station.

4. Do you provide pick-up service?

Yes, of course. If you are at Wuxi airport or station, we can arrange a special bus to directly pick you up to our factory.

5. what is the PU material used in this polyurethane / polyurea foam casting machine?

Polyurethane composed of polyol and isocyanate (poly and ISO / MDI). Polyurea can also be used for waterproof, anti-corrosion and anti rust. Polyurethane can be divided into two types: soft foam and rigid foam. There are two kinds of flexible foam or rigid foam, namely open cell and closed cell foam.

6. If I need to develop a special PU raw material formula solution according to my product, can you provide it?

Yes, we can. We have a technical team of chemical engineers and process engineers, both of whom have more than 20 years of PU industry experience. We can independently develop polyurethane hard foam, polyurethane soft foam, polyurethane integral skin foam, polyurea and other raw material solutions to meet the needs of customers.

7. What is the application of Pu cotton foam machine?

PU polyurethane foam injection molding machine includes high voltage machine and low pressure machine. It can produce Pu crown plastic, Pu bed cover, Pu plastering float, Pu refrigerator board and other hard foam products; Pu soft foam products: Car cushion, car headset, memory sponge pillow, slow rebound earplugs, Pu pressure ball, children’s toys, etc.

Polyurethane PU elastomer machine produces elastomer products. PU elastomer products such as fork wheel, roller, screen, etc.

You need to tell us the specific machine application and budget, spraying or casting, and then we can recommend the appropriate machine for you.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory best selling Injection Plastique Machine - Car Seat Making 80g/s Low Pressure PU Foaming Machine – Polyurethane, The product will supply to all over the world, such as: Panama, Zurich, Johor, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.