factory customized Small Scale Shoe Making Machine - Adjustable 19m Ring Line PU Insole Moulding Machine – Polyurethane

factory customized Small Scale Shoe Making Machine - Adjustable 19m Ring Line PU Insole Moulding Machine – Polyurethane Detail:

| Name: | Insole Moulding Machine | Warranty: | 1 YEAR |

|---|---|---|---|

| Ring Line Length: | 19m (adjustable) | Advantage: | Accurate |

| After-sales Service Provided: | Free Spare Parts, Field Installation, Commissioning And Training | Station: | Customized |

| High Light: |

PU Sole Injection Molding Machine, 19m Insole Moulding Machine, PU Insole Moulding Machine |

||

PU Shoes Insole& Inserts Making Machine Polyurethane Foam Footbed Production Line Introduction: Annular automatic insole and sole production line is an ideal equipment based on our company’s independent research and development, which can save labor cost, improve production efficiency and automatic degree, also possess the characteristics of stable performance, accurate metering, high precision positioning, automatic position identifying.

| Bucket | Metering Pump | Metering Pump Motor Power | Spit Out Quality | Total Power |

| A.120L | JR9 | 0.75kw | 10-40g/s | 8.5kw |

| B.120L | JR3.6 | 0.55kw | ||

| S.2L | JR0.3 | 0.2kw |

Product composition: The equipment includes a PU foaming machine (can be low pressure or high pressure foaming machine) and a production line. Can be customized according to the needs of users to produce products. PU foaming machine: multi-layer storage tank, stainless steel lining, sandwich heating, outer wrapping insulation, adjustable temperature, safety and energy saving; Circular production line or circular production line: this is a set of moulded PU foam production line, which can produce different types of sponge products. Its sponge products (high elasticity and viscoelasticity) are mainly aimed at the middle and high-end market. For example, memory pillows, mattresses, bus and car seat cushions, bicycle and motorcycle seat cushions, assembly chairs, office chairs, sofas and other disposable molded sponges. PU sole and insole mould: adopt aluminum mould, PU sole and insole mould frame with exquisite craftsmanship: pneumatic mould frame is suitable for automobile roof, automobile instrument panel, automobile seat, backrest and large mould. It is suitable for single-machine production and on-line use of multiple units on the CD line. PLC control, compact structure, easy to use, stable performance, high productivity. Use: Polyurethane insole has outstanding characteristics, with the following 4 product advantages: 1: high resilience. 2: perspiration and air permeability. 3: mildew and antibacterial 4: washable. The insole has good resilience, compression resistance and shock absorption.

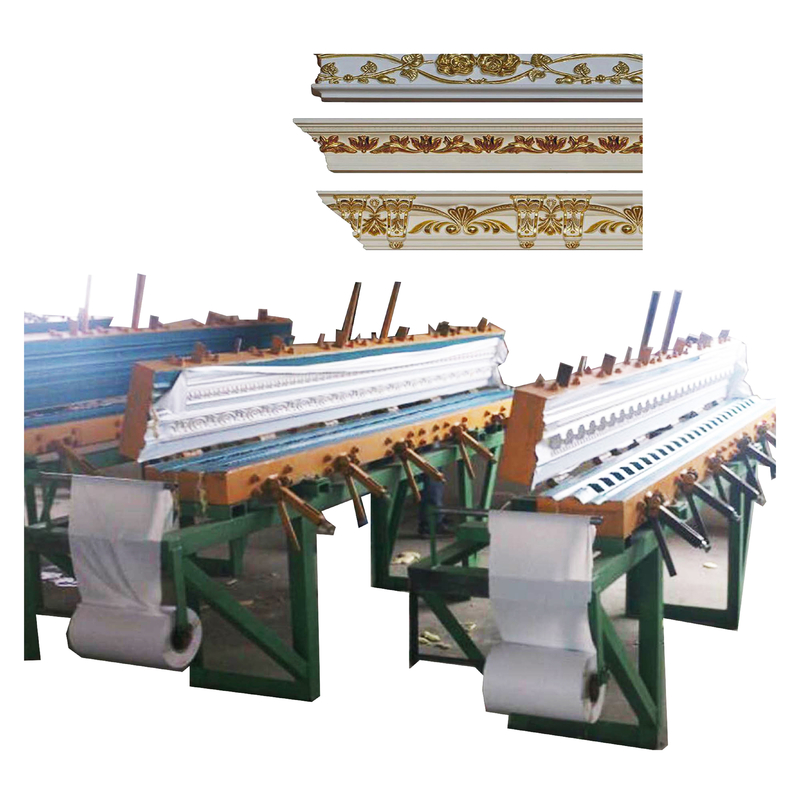

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for factory customized Small Scale Shoe Making Machine - Adjustable 19m Ring Line PU Insole Moulding Machine – Polyurethane, The product will supply to all over the world, such as: Indonesia, Paris, Mali, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.