Factory directly Foam Sound Panels - Insulated Roof 48000*8000mm PU Sandwich Panel Machine – Polyurethane

Factory directly Foam Sound Panels - Insulated Roof 48000*8000mm PU Sandwich Panel Machine – Polyurethane Detail:

PUR Polyurethane Insulated Roof Wall Panel Roofing Sheet Making Machine

| Production Line Size: | About 48000*8000mm | Pu Panel Size: | Width Max 1200mm |

|---|---|---|---|

| Panel Size: | Thickness 15~100mm | Production Speed: | 3-8 M/min |

| Total Weight: | 40T | Hot Air Circulation Temp: | 70 Degree Max |

| Minumal Cutting Length: | 1200mm | Diagonal Line Tolerance: | ± 2mm |

| Total Power: | 120kw | Port: | Ningbo For Roof Wall Panel Roll Forming Machine |

| High Light: |

8000mm PU sandwich panel line, 1200mm PU Sandwich Panel Machine, 8000mm PU Sandwich Panel Machine |

||

Product Introduction:

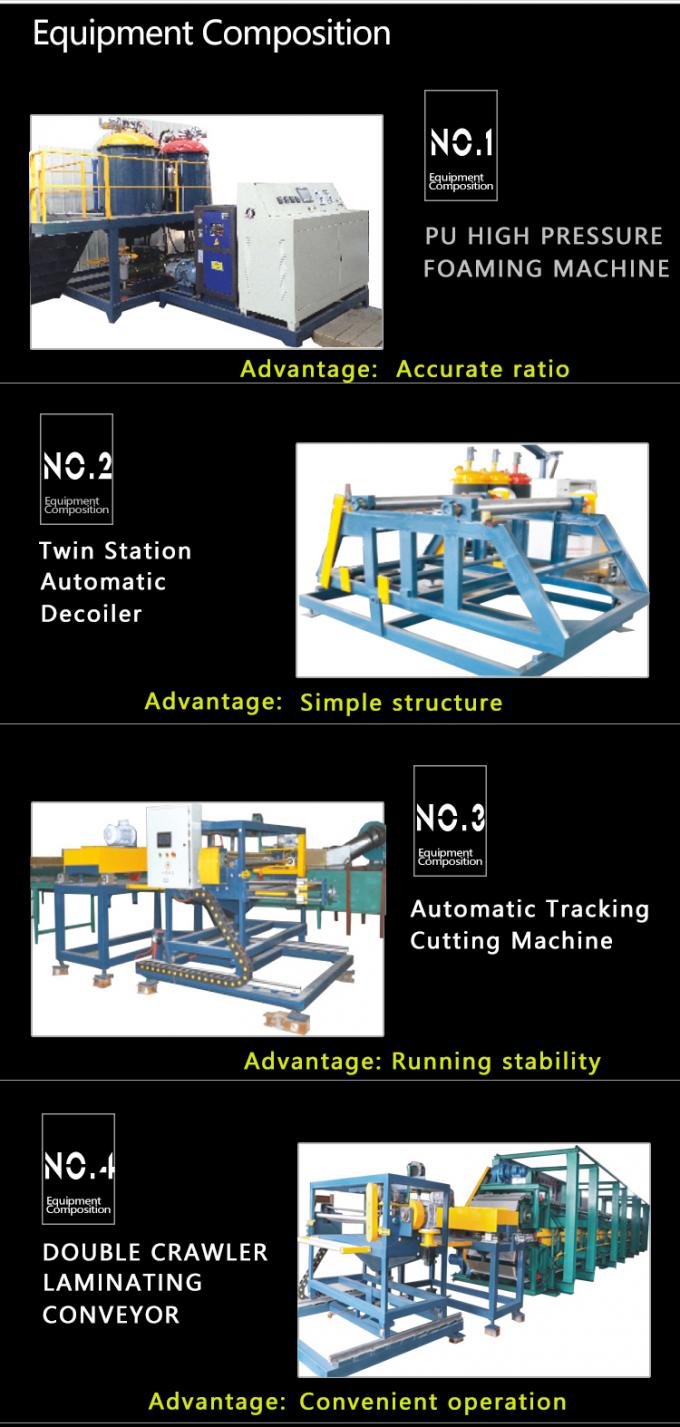

Continuous PU/PIR Sandwich Panel Production Line, also called polyurethane sandwich panel manufacturing line/production line/machine, is an automatic production line, which is consisting of decoiler, flm coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming, solidification, band saw cutting, cooling, stacking and packing. The whole PU/PIR sandwich panel production line integrates technologies of mechanics, chemistry, electrical control, hydraulic pressure pneumatic and temperature control.

Sandwich Panel Production Line Features:

1. Sandwich panel machine can product beautiful sandwich panels with high practicality, such as insulation, sound – proofing and flame retardance.

2. Hot air circulation furnace strictly controls pu foaming and solidification temperature in suitable range.

3. Precise measurement, high stability, little dust making of the high pressure foaming system protect worker’s health from harm in producing.

4. The pu sandwich panel machine using 141B(or cyclopentane), instead of CFC as vesicant, PU foaming treatment becomes an enviroment-friendly production technology.

5. Special double belt conveyor design ensures flat surface, even thickness and anti-deformation of panels.

6. PU sandwich panel machine user-friendly design and simple operation control system: HMI together with PLC computer.

Working Process Layout Of PU/PIR Sandwich Panel Production Line

Roll Forming System

There is one set roll forming machine for upper layer profiles. That is double head roll forming machine. The upper roll forming machine consists of two sets of forming rollers, one set of guiding system, one set of the transmission system, one set of frame.

Foaming Accessories

Accessories of foaming system include sheet transmission conveyor, adhesive tape sealing device, sponge sealing device.

Double Belts System

DBL is mainly used to overcome the expansibility of foaming and make it solid, and decide panel thickness and production speed. Side belt is overcome horizontal expansion and decide the width of panel and guiding to the panels.

Features Of PU Sandwich Wall Panels

PU Sandwich Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core high density POLYURETAHE foam.

PU SANDWICH PANEL are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure.

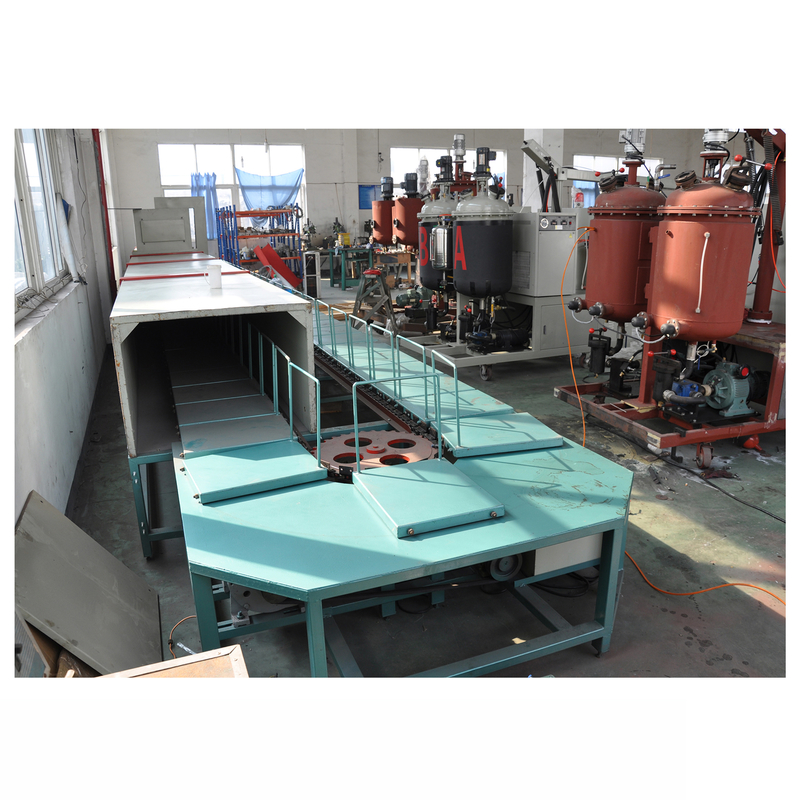

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of Factory directly Foam Sound Panels - Insulated Roof 48000*8000mm PU Sandwich Panel Machine – Polyurethane, The product will supply to all over the world, such as: kazan, Brasilia, UK, We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products supremely adored and appreciated by our customers worldwide.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!