Factory directly Spray Foam Rig Setup - 11KW Polyurethane PU 12m Bus Seat Making Machine – Polyurethane

Factory directly Spray Foam Rig Setup - 11KW Polyurethane PU 12m Bus Seat Making Machine – Polyurethane Detail:

| Processing Type: | Foaming Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net, PU Flexible Foam | Voltage: | 380V, 220V |

| Dimension(L*W*H): | Customized | Warranty: | 1 YEAR, Life-time |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| Applicable Industries: | Manufacturing Plant | Name: | Bus Seat Production Line |

| Raw Material: | Pu(=iso+poly) | Product: | Car Seat Mat |

| Usage: | Wide Usage | Other Name: | PU Car Seats Production Line |

| Color: | Customised | Power: | 11KW |

| Weight: | Customized | Port: | Shanghai For Car Seat Production Line |

| High Light: |

11KW car mat making machine, 11KW Bus Seat Making Machine, 12m Bus Seat Making Machine |

||

Automated Polyurethane PU Car Bus Seat Foaming Production LineIntroduction: Main unit: Material injection by a precision needle valve, which is taper sealed, never worn, and never clogged; the mixing head produces complete material stirring; precise metering (K series precision metering pump control is exclsively adopted); single button operation for convenient operation; switching to a different density or color at any time; easy to maintain and operate.

Control: Microcomputer PLC control; TIAN electrical components exclsively imported to achieve the goal for automatic, accurate and reliable control can be imputed with more than 500 working position data; pressure, temperature and rotation rate digital tracking and display and automatic control; abnormity or fault alarm devices. Imported frequency converter (PLC) can control the proportion of 8 different products.

| PU machine | High pressure machine, 4 comp. mixhead system |

| Production method | Continuous moving type by turn table |

| Robot | Capacity 165kg |

| PU injection | 1) Automatic pouring into open mould by industrial Robot 2) Manual pouring by worker |

| Mould carrier type | 1) Open and close by hydraulic 2) Open and close by Guide steel bar |

| Mould locking and unlocking | Auto. locking & unlocking by air unit |

| Mould carrier | 4~24 carriers |

| Line size | Approx. 4~12m(D) x 5m(H) |

| Line speed | Approx. 100~200mm/ sec, changeable type |

| The shot cycle time | Approx. 10~15 sec |

| Curing time | Approx. 4min |

| Heating unit | 4 kw/h (2carrier/ one heating unit), Hot water by electric heating |

| Seat weight | Approx. Min 310g~ Max 3,200g |

| Seat consists | Front cushion and back Rear cushion and back |

Product application:

This production line is used to produce all type of polyurethane seat cushion. For example: car seat cushion, furniture seat cushion, motorcycle seat cushion, bicycle seat cushion, office chair, ect.

Product component:

This equipment includes one pu foaming machine(can be low or high pressure foam machine) and one production line.It can be customized according to the products which the users need to produce. Mold And Applications: This is one set of molded pu foaming production line, it can produce different types of sponges products. Its sponges products(high-resilient and viscoelastic) are mainly for high and medium level markets. For example, memory pillow,mattress, bus and car seat mat, bicycle and motorcycle seat mat, assembly chair, office chair, sofa and other one-time molded sponges.

Mold And Applications: This is one set of molded pu foaming production line, it can produce different types of sponges products. Its sponges products(high-resilient and viscoelastic) are mainly for high and medium level markets. For example, memory pillow,mattress, bus and car seat mat, bicycle and motorcycle seat mat, assembly chair, office chair, sofa and other one-time molded sponges. Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Team:

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

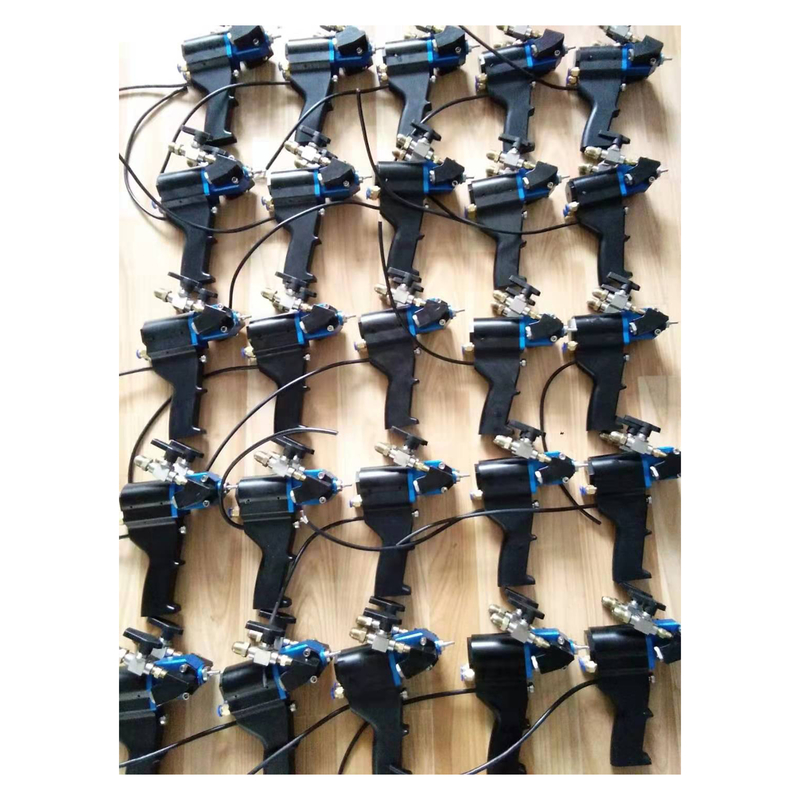

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Factory directly Spray Foam Rig Setup - 11KW Polyurethane PU 12m Bus Seat Making Machine – Polyurethane, The product will supply to all over the world, such as: Amsterdam, Poland, Borussia Dortmund, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.