Factory For Closed Cell Foam Molding - Plastic Baseball Bat PU Polyurethane Foam Molds – Polyurethane

Factory For Closed Cell Foam Molding - Plastic Baseball Bat PU Polyurethane Foam Molds – Polyurethane Detail:

PU Polyurethane Plastic Injection Mold For Plastic Baseball Bat

Introduction:

The baseball bat is made of soft foam to keep kids safe when playing. Never worring about your kids getting hit by a hard baseball and now enjoy baseball game safely!

The high-density foam allows the bat to stand up to contact over and over again, giving it a durable edge.

Fine and gross motor skills hit it off as kids use a variety of bat grips and upper body strength to swing and make contact with the ball. During play, social and emotional development excels while working as a team and cheering on peers.

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production |

| Certificate | ISO 9001:2008 |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Production Raw material | PP,PU,ABS,PE,PC,POM,PVC etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

| Lead time | 25~30 days |

| Month Production | 50 sets/month |

| Mold Packing | standard exporting Wooden case |

Baseball Bat Injection Mold Mould:

1. ISO 2000 certification.

2. One stop solution

3. Die life, 1 million needles

Advantages of our baseball bat injection mold:

1) ISO9001 TS16949 and ISO14001 enterprise system, ERP management system 2) engaged in precision plastic mold manufacturing for more than 16 years and accumulated rich experience 3) stable technical team and frequent training system, and middle-level managers have worked in this workshop for more than 10 years 4) advanced processing equipment, precision wirect in CNC centers in Sweden, mirror EDM and Japan

Our professional one-stop plastic mold customization service:

1) Provide customers with baseball bat injection mold design and image design services.

2) Plastic injection mold production, secondary injection mold, gas assisted mold.

3) Precision plastic molding: secondary shot blasting molding, precision plastic molding, gas assisted molding.

4) Secondary processing of plastics, such as wire spraying, UV, Pu spraying, hot stamping, laser engraving, ultrasonic welding, electroplating, etc.

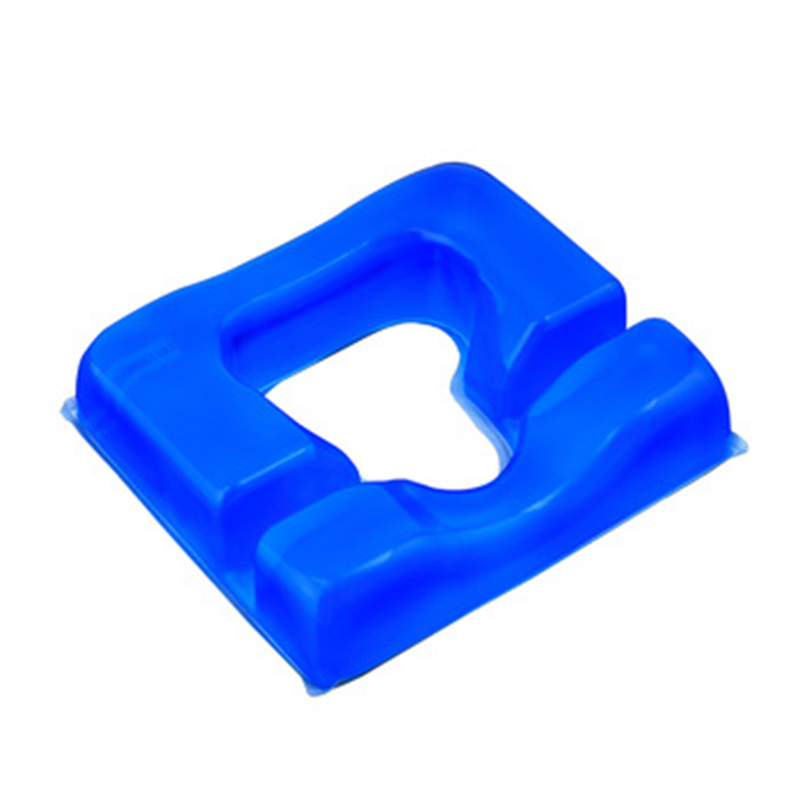

Product detail pictures:

Related Product Guide:

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for Factory For Closed Cell Foam Molding - Plastic Baseball Bat PU Polyurethane Foam Molds – Polyurethane, The product will supply to all over the world, such as: Berlin, Egypt, Cape Town, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.