Factory making Shoe Lasting Machine - Automatic Polyurethane PU Soft Foam Pouring Shoe Sole Making Machine – Polyurethane

Factory making Shoe Lasting Machine - Automatic Polyurethane PU Soft Foam Pouring Shoe Sole Making Machine – Polyurethane Detail:

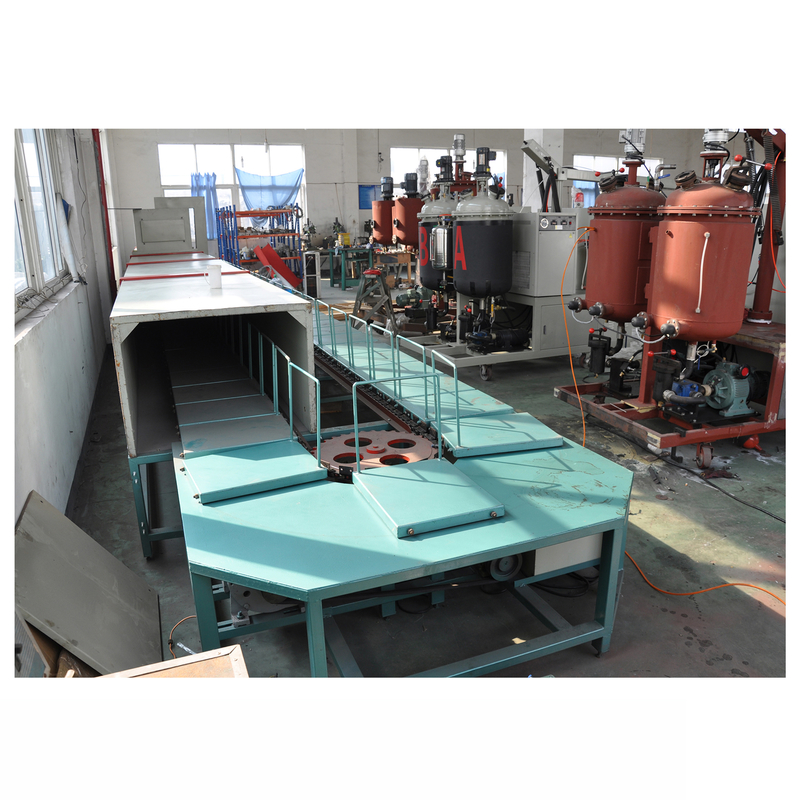

Automatic Polyurethane PU Soft Foam Pouring Shoe Sole Making Machine

Introduction:

Annular automatic insole and sole production line is an ideal equipment based on our company’s independent research and development, which can save labor cost, improve production efficiency and automatic degree, also possess the characteristics of stable performance, accurate metering, high precision positioning, automatic position identifying.

| Bucket | Metering Pump | Metering Pump Motor Power | Spit Out Quality | Total Power |

| A.120L | JR9 | 0.75kw | 10-40g/s | 8.5kw |

| B.120L | JR3.6 | 0.55kw | ||

| S.2L | JR0.3 | 0.2kw |

Technical parameters of pu shoe production line:

1. Annular line length 19000, drive motor power 3 kw/GP, frequency control;

2. Station 60;

3. Oven length 14000, heating power 28kw, inner motor power 7 * 1.5 kw;

4. Mold opening and clamping adopt servo motor 1.5kw,, reducer PF – 115-32;

5. The panasonic PLC control, 10 inch touch screen;

6. Manufacturing process: injection mold release – hand set pieces – clamping – open die – casting mould – the – - cure – lock -molding – artificial pick-up – clean up mold

Product component:

This equipment includes one pu foaming machine(can be low or high pressure foam machine) and one production line.It can be customized according to the products which the users need to produce. Main unit: Material injection by a precision needle valve, which is taper sealed, never worn, and never clogged; the mixing head produces complete material stirring; precise metering (K series precision metering pump control is exclsively adopted); single button operation for convenient operation; switching to a different density or color at any time; easy to maintain and operate. Control: Microcomputer PLC control; TIAN electrical components exclsively imported to achieve the goal for automatic, accurate and reliable control can be imputed with more than 500 working position data; pressure, temperature and rotation rate digital tracking and display and automatic control; abnormity or fault alarm devices. Imported frequency converter (PLC) can control the proportion of 8 different products. This is one set of molded pu foaming production line, it can produce different types of sponges products. Its sponges products(high-resilient and viscoelastic) are mainly for high and medium level markets. For example, memory pillow, mattress, bus and car seat mat, bicycle and motorcycle seat mat, assembly chair, office chair, sofa and other one-time molded sponges.

Application:

Every safety shoe manufacturer looks for long lasting and comfortable materials to manufacture its products and the PU sole meets these requirements of the manufacturer. PU soles are light and abrasion resistant¸ which makes it perfect for manufacturing of hard wearing shoes. This sole material comes with long-term mechanical properties and is water resistant too.

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company’s products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Product detail pictures:

Related Product Guide:

We attempt for excellence, provider the customers", hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Factory making Shoe Lasting Machine - Automatic Polyurethane PU Soft Foam Pouring Shoe Sole Making Machine – Polyurethane, The product will supply to all over the world, such as: Swiss, Borussia Dortmund, Bogota, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.