factory Outlets for Pu Foam Molded Seat - CE Mattress Pouring High Pressure PU Foaming Machine – Polyurethane

factory Outlets for Pu Foam Molded Seat - CE Mattress Pouring High Pressure PU Foaming Machine – Polyurethane Detail:

CE Mattress Pouring High Pressure PU Foaming Machine CNC PU Foam Sealing Gasket Making Machine For Electrical Enclosure combines with smart control system, performs perfectly the function of waterproof, dust-proof and noise-reduction. With the key features of fast response, high accuracy, stable performance and easy handling, which has been used in wide range of industries, such as power distribution cabinets, auto parts, electronics and electrical, lighting, filters, packing and so on. 1) Intelligent operation simulation, fast speed.2) High efficiency, save labor, time and effort.3) Low raw material cost.4) Good resilience, no joint.5) Smooth turn, not easy to fall off, beautiful.

CNC PU Foam Sealing Gasket Making Machine For Electrical Enclosure combines with smart control system, performs perfectly the function of waterproof, dust-proof and noise-reduction. With the key features of fast response, high accuracy, stable performance and easy handling, which has been used in wide range of industries, such as power distribution cabinets, auto parts, electronics and electrical, lighting, filters, packing and so on. 1) Intelligent operation simulation, fast speed.2) High efficiency, save labor, time and effort.3) Low raw material cost.4) Good resilience, no joint.5) Smooth turn, not easy to fall off, beautiful.

High voltage PU machine features:

1. Three-layer storage tank, stainless steel lining, sandwich type heating, wrapped insulation layer, adjustable temperature, safety and energy saving;

2, add material sample test system, can freely switch, does not affect the normal production, save time and materials;

3. Low speed high precision metering pump, accurate proportion, random error within ±0.5%;

4, frequency conversion speed control frequency conversion motor to adjust the material flow and pressure, high precision, quantitative adjustment simple and fast;

5. High performance mixing device, accurate synchronization of material output, uniform mixing. New leakproof structure, reserved cold water circulation interface, to ensure no blockage in long time shutdown;

6. PLC and touch screen man-machine interface control injection, automatic cleaning and air flushing, stable performance, strong operability, automatic identification, diagnosis and alarm abnormal conditions, abnormal factors display.

Material box:

These are tanks A and B of the polyurethane high-pressure machine. Polyurethane and isocyanate raw materials are installed separately.

Storage tank material: SS304

Feed flange size: φ150

Capacity: 250 litres

Quantity: 2

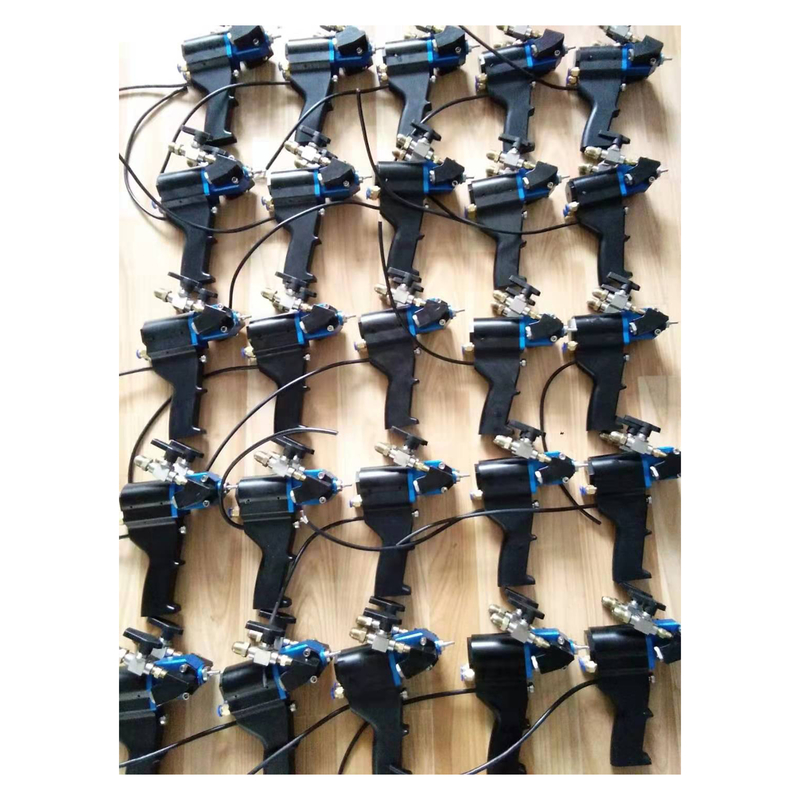

Mixing head:

Mixing head with floating mechanical seal, high shear mixing screw head, mixing two better performance materials (polyurethane and isocyanate). The mixing blade is used to stir raw materials at high speed in the mixing chamber to achieve the mixing effect, so that the liquid is evenly sprayed and the required product is formed.

Electrical control system:

1. Completely controlled by single chip microcomputer.

2. Use PCL touch screen computer. Temperature, pressure, speed display system.

3. Alarm function with sound alarm.

Product detail pictures:

Related Product Guide:

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for factory Outlets for Pu Foam Molded Seat - CE Mattress Pouring High Pressure PU Foaming Machine – Polyurethane, The product will supply to all over the world, such as: Finland, Mauritius, Luxemburg, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

We have been looking for a professional and responsible supplier, and now we find it.