factory Outlets for Pu Foam Molded Seat - Office Chair Foam Cushion Molding High Pressure PU Foaming Machine – Polyurethane

factory Outlets for Pu Foam Molded Seat - Office Chair Foam Cushion Molding High Pressure PU Foaming Machine – Polyurethane Detail:

| Name: | Pu Foam Machine | Foaming Principle: | High Pressure Air Type |

|---|---|---|---|

| Mixing Ratio Range: | 1:3~3:1(adjustable) | Pouring Volume (g/s): | 160-860g/s |

| Raw Material: | POL+ISO | Applications: | Office Chair Seat Cushion |

| High Light: |

860g/s High Pressure PU Foaming Machine, Chair High Pressure PU Foaming Machine, 860g/s chair molding machine |

||

Office Chair Foam Cushion Molding High Pressure PU Foaming Machine Description of pu foam machinery: High pressure PU foaming machine is one of our bestsellers, its main and key original parts are imported from Germany,Italy, and other countries. It has thecharacteristics of easy to operate, stable performance, energy saving and so on. Technical Parameter:

| Specification for high pressure machine | ||||

| Model No. | Output(g/s) | tank volume(L) | mixing ratio | total Power(kw) |

| SPU-H2-L80F | 160-800 | 280 | 1:3~3:1(adjustable) | 18 |

Application of pu pouring machine: In addition to maintaining a good body curve, what a chair must not forget is to sit comfortably, and to sit comfortably, the cushion is of course extremely important. Generally speaking, the chair cushion is best formed in one piece. In order to maintain elasticity and not easy to deform, and because the influence of muscles on supporting the body is extremely important, a good cushion must naturally give the body proper support, thereby reducing fatigue, so the softness of the chair cushion is too high or too low. This also involves a person's weight, but a chair cushion of really good quality will generally still have a certain degree of weight tolerance, even if the user sits on it for a long time, it will not feel excessively tired.

Product Features:

1.Material injection mixing head can freely move forward and backward, left and right, up and down;

2.Pressure needle valves of black and white materials locked after balanced to avoid pressure difference

3.Magnetic coupler adopts high-tech permanent magnet control, no leakage and temperature rising

4.Automatic gun cleaning after injection

5.Material injecting procedure provides 100 work stations, weight can be set directly to meet the production of multi-products

6.Mixing head adopts double proximity switch control, which can realize precise material injection.

7.Automatic switch from frequency converter soft start to high and low frequency, low-carbon , energy saving, environmental protection, greatly reduce the energy consumption

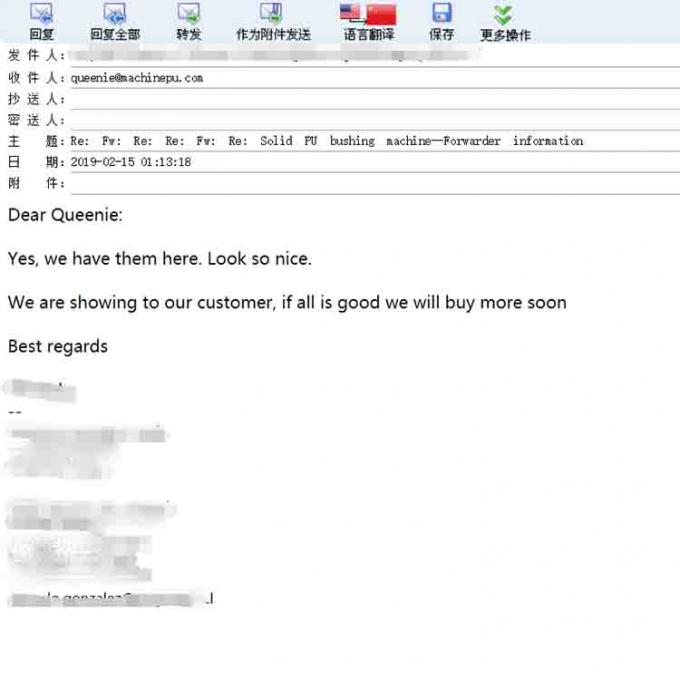

8.Full digital, modular integration control all process, accurate, safe, intuitive, intelligent and humanization Feedbacks of polyurethane injection molding machine:

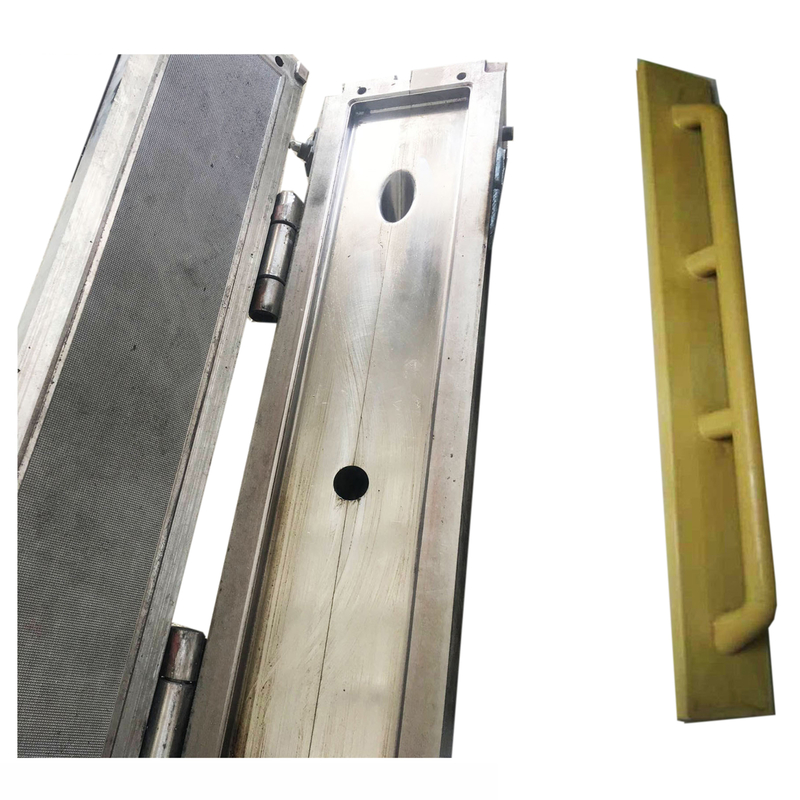

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for factory Outlets for Pu Foam Molded Seat - Office Chair Foam Cushion Molding High Pressure PU Foaming Machine – Polyurethane, The product will supply to all over the world, such as: Manchester, Rotterdam, Armenia, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.