factory Outlets for Pu Foam Molded Seat - Seat Cushion Pouring 66g/s Polyurethane Foam Equipment – Polyurethane

factory Outlets for Pu Foam Molded Seat - Seat Cushion Pouring 66g/s Polyurethane Foam Equipment – Polyurethane Detail:

| Processing Type: | Foaming Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net | Voltage: | 380 V |

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| Applicable Industries: | Manufacturing Plant | Strength 1: | Self-cleaning Filter |

| Strength 2: | Precise Metering | Feeding System: | Automatic Feeding System |

| Control System: | PLC Control System | Foam Type: | Flexible Foam |

| Output: | 16-66g/s | Tank Volume: | 250L |

| Name: | PU Foam Making Machine Customizable | Raw Material: | Polyurethane/Isocyanate |

| Power: | About 9 KW | Weight: | About 2000kg |

| Port: | Ningbo For High Pressure Polyurethane PU Foam Pouring Machine Customizable For Polyurethane Toilet Seat | ||

| High Light: |

Pouring polyurethane foam equipment, 66g/s Polyurethane Foam Machine, 250L polyurethane foam equipment |

||

Polyurethane PU Foam Pouring High Pressure Machine Customizable For Polyurethane Toilet Seat Cushion

| No. | Item | Technical parameter |

| 1 | Foam application | Integral Skin Seat |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPas ISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 400~1800g/min |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 250L |

| 15 | Temperature control system | Heat: 2×9Kw |

| 16 | Input power | Three-phase five-wire 380V |

Product Description: Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer's request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, Polyol and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

Product Features of High Pressure PU Machine:

1. Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2. Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3. Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4. Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5. High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6. Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors. Machine Part Details: Filter: Used for material filtering, adopts precision self-cleaning filter, so to avoid frequent disassembly, time saving and efficient. Mixing head: Adopt L type automatic self-cleaning mixing head, needle type nozzle adjustable, V type jet orifice, High-pressure collisional mixing principle ensure mixing effectual. Chiller: Used to supply cooling water to cooling unit,refrigeration capacity 32000Kcal/h ;(options) Application: Integral Skin baby floor seat is perfect for infant seating support. With a soft design, the seat offers a very comfortable seating position and is easy to clean. The leather-like outer foam skin is easy to clean. Simply wipe your infant floor seat with a damp cloth to remove dirt.  Other Integral Skin Products: Polyurethane integral skin foams find wide application as structural materials.Integral skin foam is used in a number of market

Other Integral Skin Products: Polyurethane integral skin foams find wide application as structural materials.Integral skin foam is used in a number of market

applications,including automotive interiors,furniture components,household leisure goods and health care products,such as wheelchairs. Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development and production. Since founded in 2013, Yongjia is the Chinese forefront polyurethane technology company with more than 10,000 square meters of construction area. At present our company's products range covers: high pressure pouring machine, low pressure foaming machine, PU/ Polyurea spraying foam machine, PU elastomer casting machine. We can also make customized production line according to clients’ different requirements.Flexible foam system:PU shoe /sole/insole production line (Egypt), anti-fatigue integral skin mat production line (Russia), memory pillow production line (Iran), high rebound pu stress ball production line (Turkey),car seat and cushion production line(Morocco), PU slow rebound ear plugs line(India);Rigid foam system:PU decorative molding crown cornice line(Saudi Arab), plastering float trowel making line(Pakistan), coldroom panel production line(Uzbekistan), normal pu sandwich panel production line(Iraq).Elastomer system:forklift wheel casting line(lran);coal sieve screen select line(Russia); car air filter gasket production line(India) and so on.Based on our extensive experience in the polyurethane machinery industry, we believe that we can meet all your needs in the polyurethane industry and sincerely look forward to your consultation and presence.

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development and production. Since founded in 2013, Yongjia is the Chinese forefront polyurethane technology company with more than 10,000 square meters of construction area. At present our company's products range covers: high pressure pouring machine, low pressure foaming machine, PU/ Polyurea spraying foam machine, PU elastomer casting machine. We can also make customized production line according to clients’ different requirements.Flexible foam system:PU shoe /sole/insole production line (Egypt), anti-fatigue integral skin mat production line (Russia), memory pillow production line (Iran), high rebound pu stress ball production line (Turkey),car seat and cushion production line(Morocco), PU slow rebound ear plugs line(India);Rigid foam system:PU decorative molding crown cornice line(Saudi Arab), plastering float trowel making line(Pakistan), coldroom panel production line(Uzbekistan), normal pu sandwich panel production line(Iraq).Elastomer system:forklift wheel casting line(lran);coal sieve screen select line(Russia); car air filter gasket production line(India) and so on.Based on our extensive experience in the polyurethane machinery industry, we believe that we can meet all your needs in the polyurethane industry and sincerely look forward to your consultation and presence.

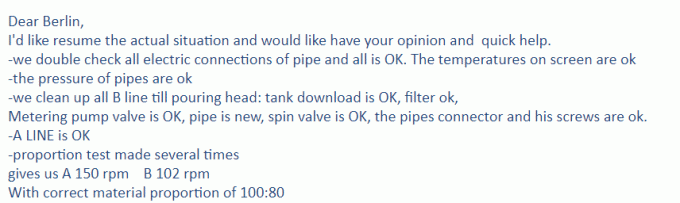

Feedback from our customer: Real comment for our PU polyurethane flexible foam shoe sole and insole making production line.

Real comment for our PU polyurethane flexible foam shoe sole and insole making production line.

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for factory Outlets for Pu Foam Molded Seat - Seat Cushion Pouring 66g/s Polyurethane Foam Equipment – Polyurethane, The product will supply to all over the world, such as: Frankfurt, Morocco, New Zealand, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.