Factory Supply Polyurethane Spray Machine - Room Insulation Polyurethane Portable Spray Foam Machine – Polyurethane

Factory Supply Polyurethane Spray Machine - Room Insulation Polyurethane Portable Spray Foam Machine – Polyurethane Detail:

| Name: | Polyurethane Spray Foam Insulation Machine | Maximum Output: | 12kg/min |

|---|---|---|---|

| Power: | 17kw | Drive Way: | Pneumatic |

| Working Pressure: | 25 Mpa | Equipped Pipe Length: | 15meters Heating Pipe |

| Ratio Between A And B: | 1:1 | Raw Material: | Polyurethane/polyurea |

| High Light: |

Polyurethane Portable Spray Foam Machine, 12kg/min Spray Foam Machine, 12kg/min polyurethane spray machine |

||

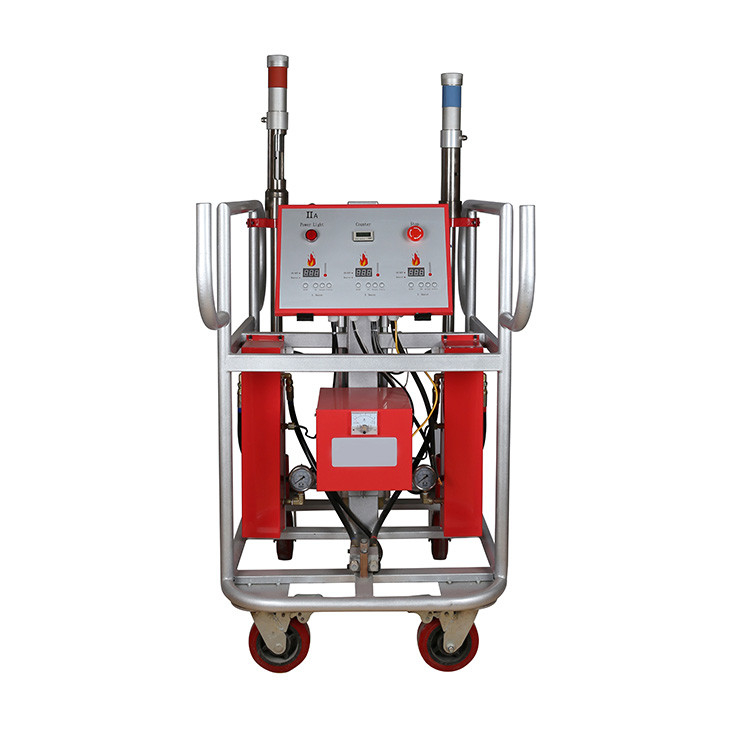

Portable Spray Foam Machine Room Insulation Polyurethane Spray Foam Machine Product Description of pu spray foam machine:JYYJ-HN35 is a professional, cost-effective polyurethane spray and injection or polyurea coating machine. It is equipped with a specially designed horizontal booster pump, which not only has small fluctuations in working pressure, but also has less wearing parts and is easy to maintain.

| SPECIFICATIONS FOR JYYJ-HN35 PU Spray Machine | ||

| Parameter | Power source | 1- phase 220V 45A |

| Heating power | 17KW | |

| Driven mode | Horizontal hydraulic | |

| Air source | 0.5-0.8 MPa ≥0.9m³/min | |

| Raw output | 12 kg/min | |

| Maximum output pressure | 25MPA | |

| Poly and ISO material output ratio | 1:1 | |

| Spare parts | Spray gun | 1 Set |

| Heating hose | 15 meters | |

| Spray gun connector | 2 m | |

| Accessories box | 1 | |

| Instruction book | 1 | |

Main Features of polyurethane foam sprayer:

1. Panel with operation tips is easy to set up,

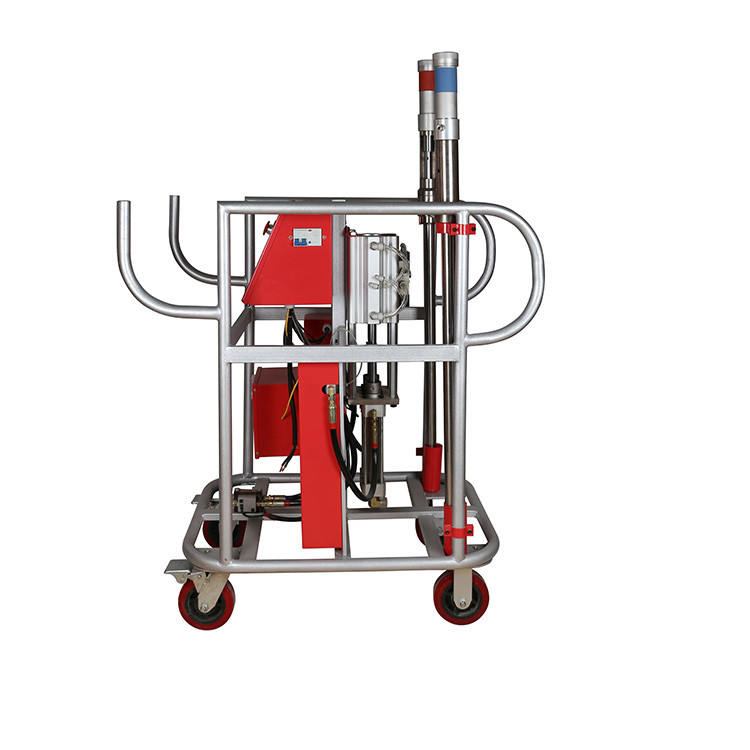

2. The horizontal booster pump adopts a coaxial mechanism and has the function of two-way supercharging. The working pressure fluctuation value is small, and the replacement of the wearing parts is simple,

3. The high-speed circulating lubricating fluid in the anti-curing lubrication cylinder can quickly take away the leakage of materials, and the ISO pump shaft is always immersed in the lubricating fluid to avoid crystallization,

4. Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range,

5. The integrated heated hose is covered with wear-resistant insulating sleeve, which not only can effectively keep the temperature of the material, but also can prevent the occurrence of leakage, short circuit, etc.

6. The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun,

7. High-precision pressure gauges are available in MPA and PSI to meet the needs of different customers,

8. Equipped with an action counter to accurately calculate the amount of raw materials,

9. The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Related Products

Related Products

| Iteam/TDS | JYYJ-3D | JYYJ-Q400 | JYYJ-H600 |

| Raw material | polyurethane | polyurea polyurethane | polyurea polyurethane |

| Features | 1. with metering control 2. Feed amount adjusted, time-set & quantity-set 3. can be used both for spraying and casting, with higher production efficiency |

1. Digital counting system( display the consumption of raw materials in real time ) 2.More light and easy to carry 3.Using 160 cylinder 4. both polyurethane and polyurea can be used |

1.can be used both for spraying and casting with higher production efficiency 2.Hydraulic driven is more stable 3. both polyurethane and polyurea can be used |

| POWER SOURCE | 1 phase 220V 50HZ | 3-phase 4-wires 380V 50HZ | 3-phase 4-wires 380V 50HZ |

| HEATING POWER (KW) | 7.5 | 18 | 22 |

| AIR SOURCE (min) | 0.5~0.8Mpa≥0.9m3 | 0.5~0.8Mpa≥1m3 | 0.5~0.8Mpa≥0.5m3 |

| OUTPUT(kg/min) | 2~12 | 2~12 | 2~12 |

| MAXIMUM OUTPUT (Mpa) | 11 | 22 | 24 |

| Matrial A:B= | 1;1 | 1;1 | 1;1 |

| spray gun:(set) | 1 | 1 | 1 |

| Feeding pump: | 2 | 2 | 2 |

| Barrel connector: | 2 sets heating | 2 sets heating | 2 sets heating |

| Heating pipe:(m) | 15-60 | 15-120 | 15-120 |

| Spray gun connector:(m) | 2 | 2 | 2 |

| Accessories box: | 1 | 1 | 1 |

| Instruction book | 1 | 1 | 1 |

| Digital counting system | √ | √ | |

| Hydraulic driven | √ | ||

| pneumatic driven | √ | √ |

Applications 1. Insulation & Coating: external wall insulation, internal wall insulation, roof, cold storage, ship cabin, cargo containers,trucks, refrigerated trucks,tank, etc.2. Casting: solar water heaters,tank insulation, cabin, insulation board, security doors, refrigerators, pipes, road construction, packaging, road construction, wall insulation, etc.

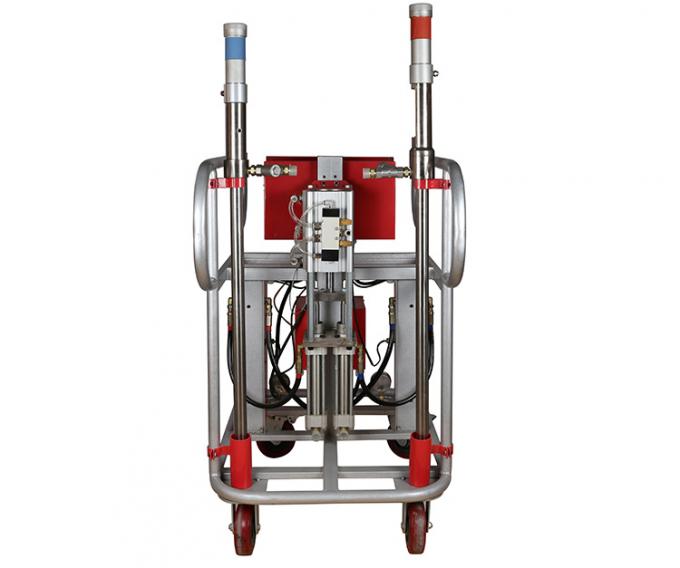

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Factory Supply Polyurethane Spray Machine - Room Insulation Polyurethane Portable Spray Foam Machine – Polyurethane, The product will supply to all over the world, such as: Malaysia, Costa Rica, Poland, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.