High definition Pu Foam Making Machine - Polyurethane Soft Upholstery Seat Cushion PU Foam Filling Machine – Polyurethane

High definition Pu Foam Making Machine - Polyurethane Soft Upholstery Seat Cushion PU Foam Filling Machine – Polyurethane Detail:

| Name: | High Pressure Pu Foam Machine | Foaming Principle: | High Pressure Air Type |

|---|---|---|---|

| Mixing Ratio Range: | 1:5~5:1(adjustable) | Injection Output (mixing Ratio 1:1): | 110-540g/s |

| Foam Type: | Soft Foam | Applications: | Anti Fatigue Mats |

| High Light: |

Upholstery Seat Cushion Foaming Machine, Upholstery Cushion PU foam filling machine, 540g/s PU foam filling machine |

||

Polyurethane Soft Foam Racing Car Upholstery Seat Cushion Making Machine High Pressure PU Foaming Machine Details of Foam Flexible Foam Injection Machine: Mixing head: Adopting Korea SPU self-cleaning L type mixing head, adjustable needle type nozzle, V-shape spraying orifice, high pressure collision mixing principle, which ensure are fully mixing of components. Electrical control system: Adopting mcgs man-computer interface, setting the injection time,test time and pressure time and etc. Temperature control unit: Temperature control unit is mainly used for temp. control of both materials and making them into integration structure. Specifications of High Pressure Foam Machine:

| No. | Item | Technical Parameter |

| 1 | Foam application | PU Soft foam |

| 2 | Raw material viscosity(22℃) | POL~2500mPas ISO ~1000mPas |

| 3 | Injection pressure | 10~20Mpa (adjustable) |

| 4 | Injection Output (mixing ratio 1:1) | 160-800g/s |

| 5 | Mixing ratio range | 1:3~3:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature control error | ±2℃ |

| 8 | Repeated injection accuracy | ±1% |

| 9 | Mixing head | Korea SPU 1218-2K, four oil hoses, double oil cylinders |

| 10 | Hydraulic system | Output 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 250L |

| 12 | Input power | Three-phase five-wire,380V 50HZ |

Equipment main technical characteristics: 1. Material injection mixing head can freely move forward and backward, left and right, up and down;2. Pressure needle valves of black and white materials locked after balanced to avoid pressure difference

3. Magnetic coupler adopts high-tech permanent magnet control, no leakage and temperature rising

4. Automatic gun cleaning after injection

5. Material injecting procedure provides 100 work stations, weight can be set directly to meet the production of multi-products

6. Mixing head adopts double proximity switch control, which can realize precise material injection.

7. Automatic switch from frequency converter soft start to high and low frequency, low-carbon , energy saving, environmental protection, greatly reduce the energy consumption

8. Full digital, modular integration control all process, accurate, safe, intuitive, intelligent and humanization  Application of polyurethane foam injection machine: Polyurethane foam can be used for everything from domestic seating, such as dining chairs and sofa cushions, to automobile and boat seats; and because quality and customer satisfaction is our main priority, we aim to deliver a product that ensures the greatest possible degree of comfort.

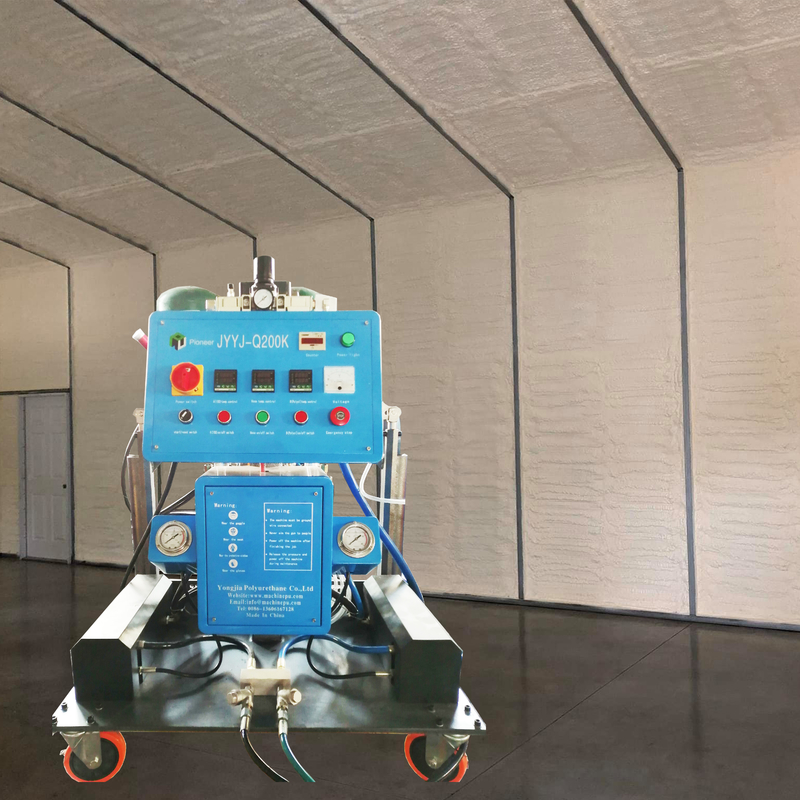

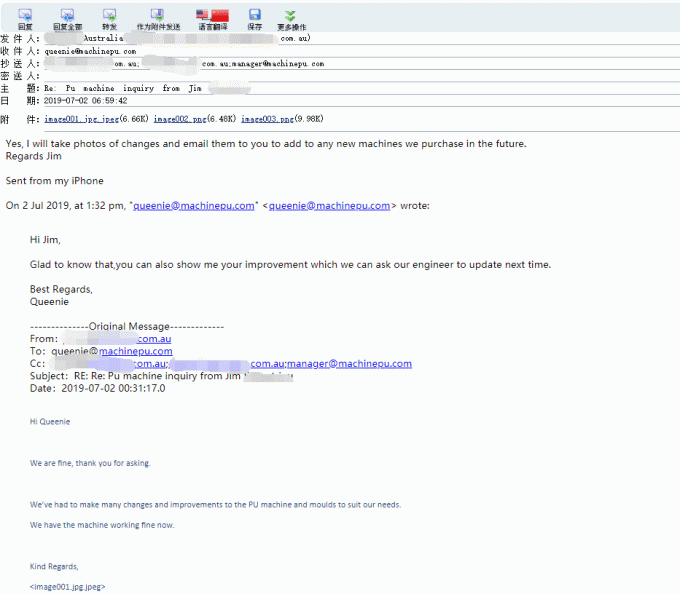

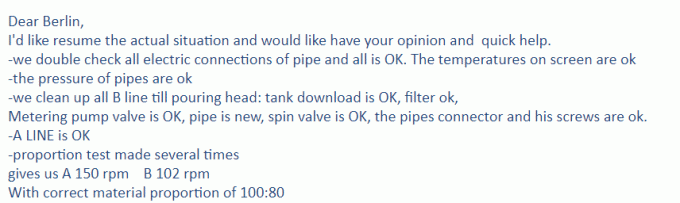

Application of polyurethane foam injection machine: Polyurethane foam can be used for everything from domestic seating, such as dining chairs and sofa cushions, to automobile and boat seats; and because quality and customer satisfaction is our main priority, we aim to deliver a product that ensures the greatest possible degree of comfort.  Feedbacks of polyurethane injection molding machine

Feedbacks of polyurethane injection molding machine

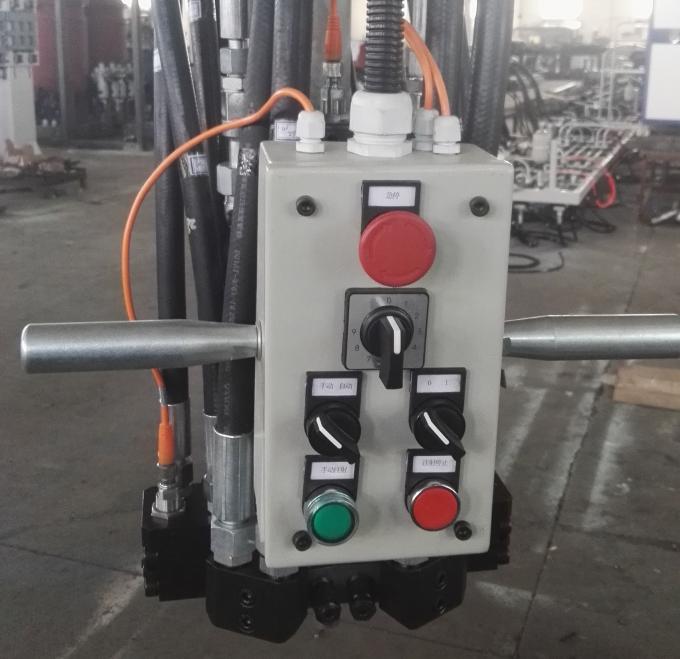

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for High definition Pu Foam Making Machine - Polyurethane Soft Upholstery Seat Cushion PU Foam Filling Machine – Polyurethane, The product will supply to all over the world, such as: Malaysia, Angola, Amsterdam, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.