Hot-selling Switchboard Polyurethane Strip Foaming Machine - PU Foam Reactor Polyurea Spray Coating Machine Polyurethane Spray Foam Machine – Polyurethane

Hot-selling Switchboard Polyurethane Strip Foaming Machine - PU Foam Reactor Polyurea Spray Coating Machine Polyurethane Spray Foam Machine – Polyurethane Detail:

| Name: | Polyurea Coating Spray Equipment | Maximum Output: | 9kg/min |

|---|---|---|---|

| Power: | 17kw | Drive Way: | Hydraulic |

| Working Pressure: | 25 Mpa | Equipped Pipe Length: | 15meters Heating Pipe |

| Ratio Between A And B: | 1:1 | Raw Material: | Polyurea |

| High Light: |

25Mpa polyurea spray machine, Coating polyurea spray machine, Coating Polyurethane Spray Foam Machine |

||

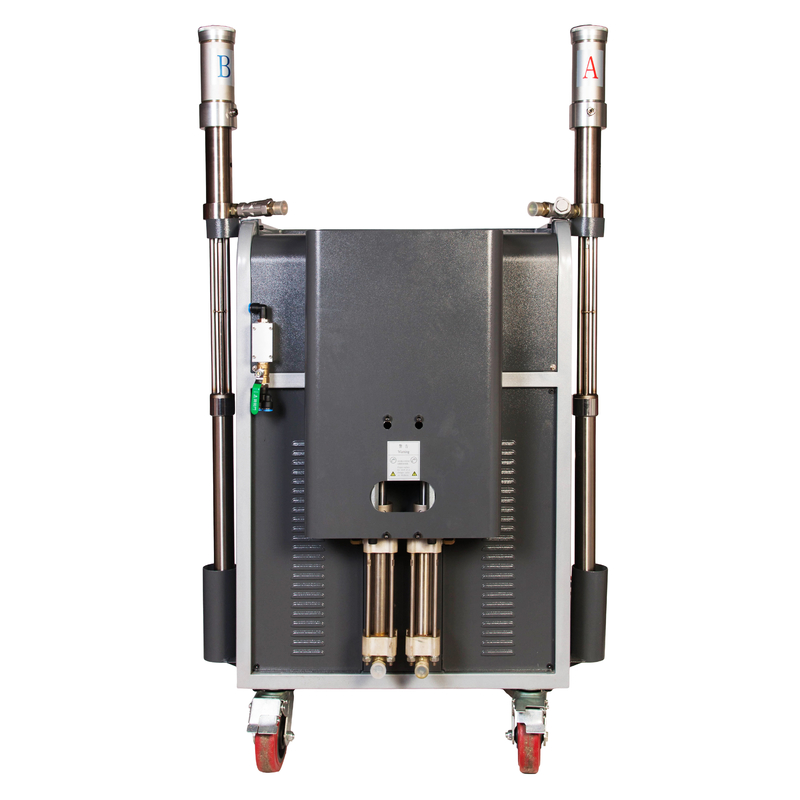

PU Foam Reactor Polyurea Spray Coating Machine Polyurethane Spray Foam Machine Product Description of polyurea coating machine: The JYYJ-HN35L polyurea spraying machine is designed for polyurea material spraying and coating. 1- Work efficiency can reach 60%or more, far greater than the 20% efficiency of the pneumatc machine.

2- Hydraulic drive less troubles.

3- Working pressure up to 25MPA and very stable, large displacement up to 9kg/mint.

4- Machine with soft start, the booster pump is equipped with an overpressure valve. When the pressure exceeds the set pressure, it will automatically release pressure and protect the machine.

5- Electrical components, testing companents, seals all are made in Germany, pumps made in Japan, solenoid valves made in Italy.

6- Only need 17kw air compressor to work together, reducing the overall working load.

7- Equip with 8inch operating touch screen PLC, the sense of technology is stronger. It's convenient to observe the working status of the machine in real time.

| Iteam/TDS | JYYJ-3D | JYYJ-Q400 | JYYJ-H600 |

| Raw material | polyurethane | polyurea polyurethane | polyurea polyurethane |

| Features | 1. with metering control 2. Feed amount adjusted, time-set & quantity-set 3. can be used both for spraying and casting, with higher production efficiency |

1. Digital counting system( display the consumption of raw materials in real time ) 2.More light and easy to carry 3.Using 160 cylinder 4. both polyurethane and polyurea can be used |

1.can be used both for spraying and casting with higher production efficiency 2.Hydraulic driven is more stable 3. both polyurethane and polyurea can be used |

| POWER SOURCE | 1 phase 220V 50HZ | 3-phase 4-wires 380V 50HZ | 3-phase 4-wires 380V 50HZ |

| HEATING POWER (KW) | 7.5 | 18 | 22 |

| AIR SOURCE (min) | 0.5~0.8Mpa≥0.9m3 | 0.5~0.8Mpa≥1m3 | 0.5~0.8Mpa≥0.5m3 |

| OUTPUT(kg/min) | 2~12 | 2~12 | 2~12 |

| MAXIMUM OUTPUT (Mpa) | 11 | 22 | 24 |

| Matrial A:B= | 1;1 | 1;1 | 1;1 |

| spray gun:(set) | 1 | 1 | 1 |

| Feeding pump: | 2 | 2 | 2 |

| Barrel connector: | 2 sets heating | 2 sets heating | 2 sets heating |

| Heating pipe:(m) | 15-60 | 15-120 | 15-120 |

| Spray gun connector:(m) | 2 | 2 | 2 |

| Accessories box: | 1 | 1 | 1 |

| Instruction book | 1 | 1 | 1 |

| Digital counting system | √ | √ | |

| Hydraulic driven | √ | ||

| pneumatic driven | √ | √ |

Applications of polyurea waterproofing material coating machine: ArmorThane has a number of pure and hybrid Polyurea and Polyurethane products for spraying secondary containment pits, containment booms or building containment berms. These products dry to form a leak-proof membrane that holds any type of liquid spills. It has the flexibility to prevent cracking with weather and ground shift. Because commercial and industrial floors take more abuse than residential surfaces, ArmorThane Polyurea and Polyurethane sprayed-on and roll-on coatings make more sense than carpet, tile, vinyl, rubber or other coatings. New or repaired surfaces are protected long term, even against corrosive chemicals and cracking or warping. Coatings are applied both inside and outdoors. Costly construction and industrial equipment is used in the most high-wear surroundings. ArmorThane offers coating solutions to protect and revitalize equipment at a fraction of the cost to replace. With ArmorThane, operators can help protect their people, products, and vehicle investment from expensive exterior damage as well as manpower downtime. Because it’s exceptionally favorable in wet conditions, ArmorThane helps to keep cargo and supplies from sliding around in the back of fleet and utility trucks, creating a more stable handling situation for operators.

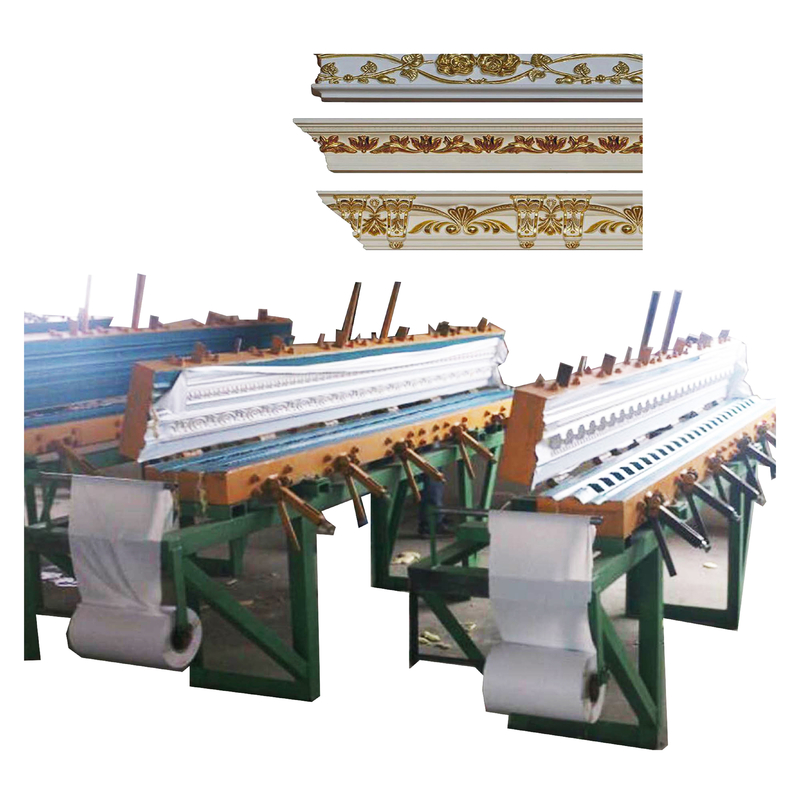

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Hot-selling Switchboard Polyurethane Strip Foaming Machine - PU Foam Reactor Polyurea Spray Coating Machine Polyurethane Spray Foam Machine – Polyurethane, The product will supply to all over the world, such as: Birmingham, Adelaide, Serbia, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.