Low MOQ for R Panel Roll Former - Door PanPU Polyurethane Insulation Sectional Garage Door Panel Cold Room Wall Panel Roll Forming Machine For Meet Fish Storage – Polyurethane

Low MOQ for R Panel Roll Former - Door PanPU Polyurethane Insulation Sectional Garage Door Panel Cold Room Wall Panel Roll Forming Machine For Meet Fish Storage – Polyurethane Detail:

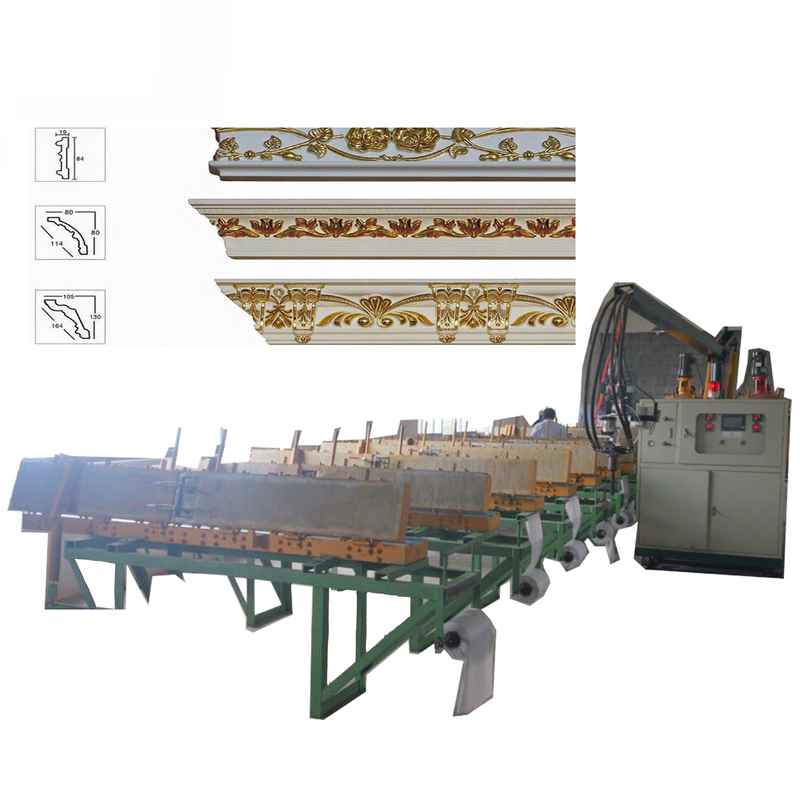

PU Polyurethane Insulation Sectional Garage Door Panel Cold Room Wall Panel Forming Machine

Introduciton:

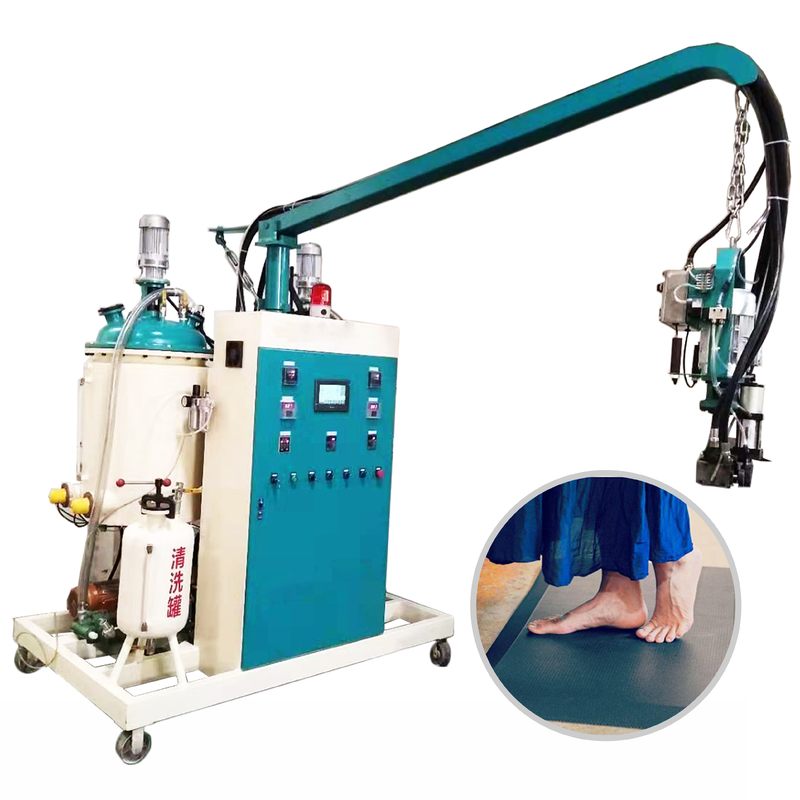

PU PIR PUR PUF Sandwich panel machine includes uncoiling system, film covering and cutting system, roll forming machine, preheating oven, high pressure foaming system, double belt conveyor, double belt heating device, cutting system, etc….The sandwich panel press machine adopts gantry lift-draw type, locates directly without any foundation. 2+2 type saves much time for panel preparation and discharge time which increase times of efficiency. The polyurethane foaming process of Yongjia can meet various needs of the construction industry. The sandwich panel production line in Yongjia can mainly produce roof panels and wall panels.

PU Sandwich wall panels are widely applied in the protection and decoration of outside wall for tall building and first-class office building. Sandwich panel can protect, keep warm and flame retarding.

Our PU sandwich panel has high strength and durability of insulating ability. In addition, we use the PIR (Poly Isocyanurate) which it has the resistance to flame so the panel has the high resistance to flame. Also HCFC-14b the blowing unit as well as the Pentane the eco-friendly material will make more safety and better environment as it’s the “GREEN” unit.

| Laminating machine parts | |||||

| number of plies | 2+2 | Load the template size | 12500*1200mm | ||

| mould height | 250mm | clamping force | 280kgf | ||

| working oil pressure | 15mpa | Heat the water pressure | 0.2mpa | ||

| water temperature | 85℃ | voltage | 380V/50HZ | ||

| power | 120kw | weight | 60T | ||

| Travelling form | |||||

| Upper mobile template operation level | 1052mm | lower speed of mobile template driven | 693mm | ||

| speed of mobile template driven | 360mm/s | ||||

| Track component | |||||

| orbit altitude | 170mm | Track length | 40500mm | ||

| Number of sets of orbit | 2sets | lay direction | Laminating machine around both ends | ||

This production line adopts European technology, cost reduced by technical transformation, which has high stiffness, strength, accuracy, and stability; polyurethane sandwich panel production line is used for the continuous production of polyurethane foam sandwich panel, such as polyurethane insulation panel with surface layer of non-woven cloth, cement mortar, kraft paper or aluminum foil.

PU COLDROOM PANEL are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure.

Industrial buildings.

Steel frame structure buildings

Store houses and logistic centres

Commercial buildings and offices

Fire Rated Buildings

Agricultural objects

Sport halls

Logistics centers

PU Cold Room Panels with polyurethane foam cores meet the strictest heat insulation requirements, while also complying with the required insulation properties and maintaining a good load bearing capacity.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for Low MOQ for R Panel Roll Former - Door PanPU Polyurethane Insulation Sectional Garage Door Panel Cold Room Wall Panel Roll Forming Machine For Meet Fish Storage – Polyurethane, The product will supply to all over the world, such as: Guatemala, Saudi Arabia, South Korea, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly