OEM Factory for Resin Casting Machine - The Single Slide Car Air Oil Filter Plastic Injection Molding Making Machine – Polyurethane

OEM Factory for Resin Casting Machine - The Single Slide Car Air Oil Filter Plastic Injection Molding Making Machine – Polyurethane Detail:

The Single Slide Car Air Oil Filter Plastic Injection Molding Making Machine

Introduction Of Air Filter Gasket Casting Machine:

Automatic sealing strip casting machine is widely employed in the foaming production of electric cabinet door panel, automobile air filter and other products. This machine has high repeat injection precision, even mixing, stable performance, easy operation, and high production efficiency.

| The machine model | PU20-1 | PU20-2 | PU20-3 |

| Always spit out quantity | 4 to 12 g/s | 8-30 grams/SEC. | 17-60 grams/SEC |

| The largest processing size Length x width | 400×300mm | 500×400mm | |

| The diameter of Round biggest increase | 350mm | 500mm | 500mm |

| The total power | 10KW | ||

| The power supply | 380V | ||

| The compressed air | ≥0.6MPa | ||

| The machine weighs | 550kg | ||

| The nose mixed speed | 6000 r/min | ||

| Mixed way | Dynamic hybrid | ||

| Container volume | 40L-150L | ||

| Hybrid range | B:A=25-50:100 | ||

| Measuring accuracy | ±0.5% | ||

Structure characteristics:

1. For sandwich type material bucket, it has good heat preservation

2. The adoption of PLC touch screen human-computer interface control panel makes the machine easy to use and the operating situation was absolutely clear.

3. Head fixing controlled directly by PLC operating system,easy of operation.

4.The adoption of new type mixing head makes the mixing even, with the characteristic of low noise, sturdy and durable.

5. Boom swing length customizable, multi-angle rotatable, convenient and efficient.

6. High precision pump lead to measuring accurately.

7. Easy for maintenance, operation and repair.

8. Low energy consumption.

Applications:

Fully automatic filter gasket foaming machine is widely employed in the production of automobile and industrial filters, home use filters, etc. The machine owns many advantages, such as high repeat injection precision, even mixing, stable performance, easy operation, high production efficiency, etc.

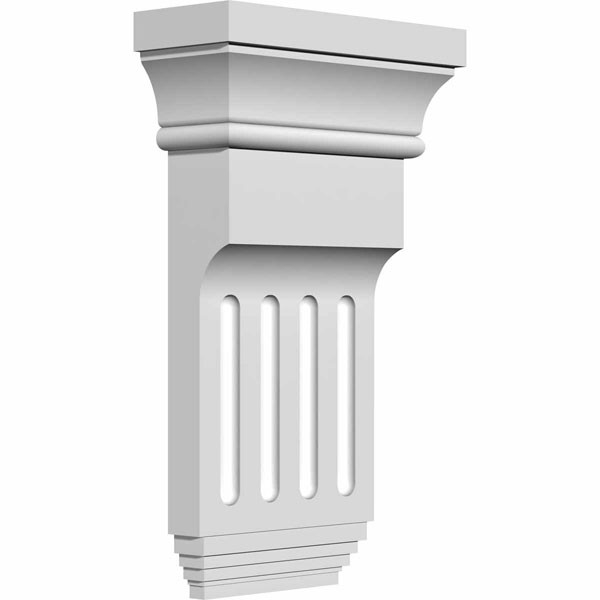

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for OEM Factory for Resin Casting Machine - The Single Slide Car Air Oil Filter Plastic Injection Molding Making Machine – Polyurethane, The product will supply to all over the world, such as: India, Australia, European, With the effort to keep pace with world's trend, we will always endeavor to meet customers' demands. If you want develop any other new products, we can customize them for you. If you feel interest in any of our products or want develop new products, please feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.