OEM/ODM Factory Crown Molding Vaulted Ceiling – Forklift Omni Wheel 5000RPM Polyurethane Casting Machine – Polyurethane

OEM/ODM Factory Crown Molding Vaulted Ceiling – Forklift Omni Wheel 5000RPM Polyurethane Casting Machine – Polyurethane Detail:

| Voltage: | 380V | Machine Type: | Foaming Machine |

|---|---|---|---|

| Dimension(L*W*H): | 2300*2000*2300 Mm | Condition: | New |

| Product Type: | Foam Net | Power (kW): | 25~31KW |

| Weight (KG): | 2000 KG | Warranty: | 1YEAR |

| Key Selling Points: | Automation | After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Local Service Location: | Turkey, Pakistan, India | Showroom Location: | Turkey, Pakistan, India |

| Applicable Industries: | Manufacturing Plant, Construction Works | Key Words: | PU Balance Wheel For Forklift Truck |

| Mix Head: | Mix Evenly, No Bubble | Injection Pressure: | 0.01-0.1Mpa |

| Injection Time: | 0.5~99.99S (correct To 0.01S) | Temperature Control: | ±2℃ |

| Repeated Injection Accuracy: | ±1% | Color: | Deep Blue/cream Color/red |

| Ratio Between A And B: | 1 : 1 | Raw Material: | Polyurethane And Isocyanate |

| Port: | Ningbo | ||

| High Light: |

5000RPM PU casting machine, 380V Polyurethane Casting Machine, 5000RPM Polyurethane Casting Machine |

||

PU Elastomer Polyurethane Casting Machine For Forklift Omni Wheel Making Application: Suitable for PU fork wheel:The cast polyurethane rubber wheel is formed by the pouring process, pouring and reaction molding of liquid resin!It can also be referred to as “PU rubber wheel”, and this type of liquid raw material system is also called “liquid rubber”.1. Pouring liquid raw materials into product molds, reacting and solidifying molding, can be directly made into thick and bulky polyurethane rubber rollers and polyurethane products with complex shapes or non-standard parts.2. The polyurethane rubber roller produced by this process has good comprehensive performance!

PU Elastomer Casting Machine Introduction: Polyurethane elastomer pouring machine is a kind of equipment for producing castable polyurethane elastomer with MOCA or BDO as chain extender. PU elastomer casting machine is suitable for manufacturing various CPU products, such as seals, grinding wheels, rollers, screens, impellers, OA machines, wheel sliding wheels, buffers and so on.

| No. | Item | Technical Parameter |

| 1 | Injection Pressure | 0.1-0.6Mpa |

| 2 | Injection flow rate | 2-5kg/min |

| 3 | Mixing ratio range | 100:6-18(adjustable) |

| 4 | Injection time | 0.5~99.99S (correct to 0.01S) |

| 5 | Temperature control error | ±2℃ |

| 6 | Repeated injection precision | ±1% |

| 7 | Mixing head | Around 5000rpm (4600~6200rpm,adjustable), forced dynamic mixing |

| 8 | Tank volume | 220L/30L |

| A maximum working temperature | 70~110℃ | |

| B maximum working temperature | 110~130℃ | |

| 9 | Cleaning tank | 20L 304# stainless steel |

| 10 | Metering pump | JR50/JR50/JR9 |

| A1 A2 Metering pump displacement | 50CC/r | |

| B Metering pump displacement | 6CC/r | |

| A1-A2-B-C1-C2 PUMPS MAXIMUM SPEED | 150RPM | |

| A1 A2 agitator speed | 23RPM | |

| 11 | Compressed air requirement | Dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

| 12 | Vacuum requirement | P:6X10-2Pa(6 BAR) Speed of exhaust:15L/S |

| 13 | Temperature control system | Heating: 18~24KW |

| 14 | Input power | Three-phrase five-wire,380V 50HZ |

| 15 | Heating power | TANK A1/A2: 4.6KW TANK B: 7.2KW |

| 16 | Total power | 34KW |

| 17 | Working Temperature | Room temperature to 200℃ |

| 18 | Swing arm | Fixed arm, 1 meter |

| 19 | Volume | About 2300*2000*2300(mm) |

| 20 | Color (selectable) | Deep blue |

| 21 | Weight | 2000Kg |

Product Features of PU Elastomer Casting Machine:

High temperature resistant low-speed high-precision metering pump, accurate metering, and the random error is within ± 0.5%. The material output is regulated by frequency converter and frequency conversion motor, with high precision pressure and simple and fast speed ratio control. High performance mixing device, adjustable pressure, synchronous and accurate material output and uniform mixing; New mechanical seal structure to avoid backflow problem. Special mixing head high-efficiency vacuum device to ensure that the product is free of bubbles. The heat transfer oil adopts electromagnetic heating mode, which is efficient and energy-saving; Multipoint temperature control system, stable temperature, random error < ± 2 ℃. It adopts PLC and touch screen man-machine interface to control pouring, automatic cleaning and flushing, air purification and stability

Performance. Strong operability, can automatically identify, diagnose, alarm abnormal conditions and display abnormal factors.

storage panel production line(Uzbekistan),sandwich panel

storage panel production line(Uzbekistan),sandwich panel

Our Service:

1. Professional and patient consulting services to help you find the right solution.

2. Further negotiate technical details, machine configuration, price basis, payment method and delivery date.

3. Have strong control over the production progress and quality of the machine, and inform you of the details in time.

4. Free training in our factory during machine inspection. Or photos and videos of the machine and packaging for your confirmation before shipment.

5. Fast and safe shipping according to your requirements, including space booking, container loading and shipping documents.

6. In terms of technical support, we can help you online through e-mail and telephone. If necessary, we can also send technicians to your site.

7. For spare parts, we will provide them free of charge within the one-year warranty period, and the spare parts will be supplied at the original price during the warranty period.

8. We give a free accessory box.

9. We provide development solutions for raw material formulations.

10. If you need to visit the factory, we will arrange personnel to pick you up at the airport.

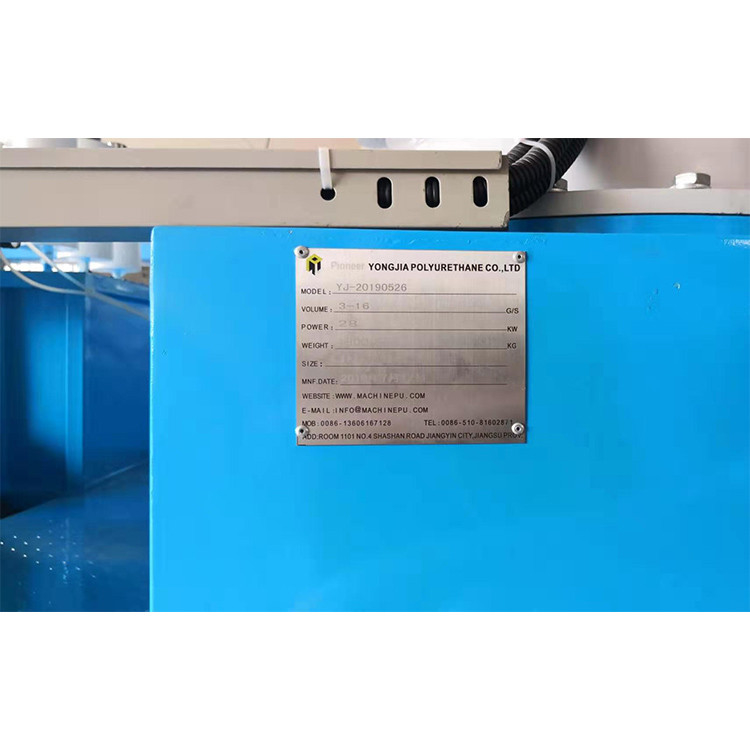

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with OEM/ODM Factory Crown Molding Vaulted Ceiling – Forklift Omni Wheel 5000RPM Polyurethane Casting Machine – Polyurethane, The product will supply to all over the world, such as: Monaco, Senegal, Russia, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.