One of Hottest for Automatic Polyurethane Pu Foaming Machine - CE Mattress Pouring High Pressure PU Foaming Machine – Polyurethane

One of Hottest for Automatic Polyurethane Pu Foaming Machine - CE Mattress Pouring High Pressure PU Foaming Machine – Polyurethane Detail:

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Processing Type: | Foaming Machine |

|---|---|---|---|

| Condition: | New | Product Type: | Foam Net |

| Machine Type: | Foaming Machine | Voltage: | 380V |

| Power (kW): | 9kW | Weight (KG): | 2000 KG |

| Warranty: | 1 YEAR | After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support |

| Key Selling Points: | Automatic | After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Local Service Location: | Turkey, Pakistan, India | Applicable Industries: | Manufacturing Plant |

| Strength 1: | Self-cleaning Filter | Strength 2: | Automatic Feeding System |

| Strength 3: | PLC Control System | Strength 4: | Precise Metering |

| Tank Volume: | 250L | Power: | Three-phase Five-wire 380V |

| Name: | Polyurethane Resin Grouting Materials | Port: | Ningbo For Polyurethane Resin Grouting Materials |

| High Light: |

pouring high pressure pu foaming machine, 250L PUF pouring machine, CE High Pressure PU Foaming Machine |

||

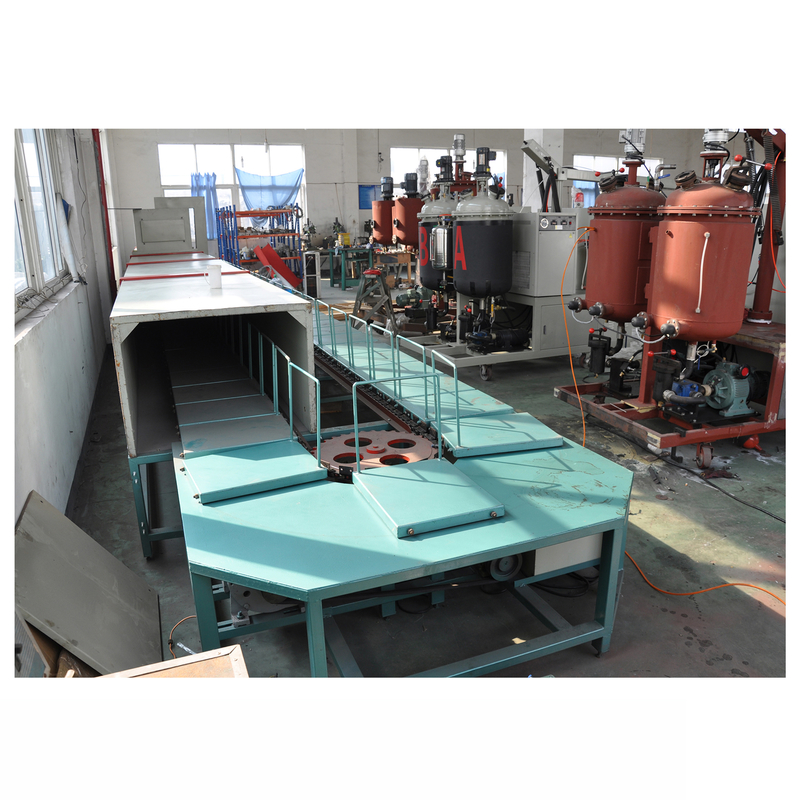

High Pressure PU Polyurethane Pouring Making Machine For Polyurethane Mattress Product Description: Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine. Application: Polyurethane Foam (also known as poly-foam) is the least expensive and lowest quality foam used in mattresses and mattress toppers. … Many mattress manufacturers use polyurethane foam as the top layer of spring mattresses. This is done primarily because polyurethane is very inexpensive, not because it is high quality.

Product Description: Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine. Application: Polyurethane Foam (also known as poly-foam) is the least expensive and lowest quality foam used in mattresses and mattress toppers. … Many mattress manufacturers use polyurethane foam as the top layer of spring mattresses. This is done primarily because polyurethane is very inexpensive, not because it is high quality.

| No. | Item | Technical parameter |

| 1 | Foam application | Flexible Foam Mattress Foam |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPas ISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 375~1875g/min |

| 5 | Mixing ratio range | 1:3~3:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 280L |

| 15 | Temperature control system | Heat: 2×9Kw |

| 16 | Input power | Three-phase five-wire 380V |

Features of high voltage Pu machine:

1. Three layer storage tank, stainless steel lining, sandwich heating, wrapped with insulation layer, adjustable temperature, safety and energy saving;

2. Add a material sample test system, which can be switched freely without affecting normal production and saving time and materials;

3. Low speed and high-precision metering pump, accurate proportioning, and random error within ± 0.5%;

4. The material flow and pressure are regulated by frequency conversion motor with high precision and simple and fast proportional regulation;

5. High performance mixing device, accurate synchronous material output and uniform mixing. New leak proof structure, reserved cold water circulation interface to ensure long-term shutdown without blockage;

6. PLC and touch screen man-machine interface are used to control oil injection, automatic cleaning and air blowing. It has stable performance and high operability. It can automatically identify, diagnose and alarm abnormal conditions and display abnormal factors.

Material tank:

These are tanks a and B of polyurethane high pressure machine. Polyurethane and isocyanate raw materials are installed separately.

Water tank material: SS304

Feed flange size: φ one hundred and fifty

Capacity: 250L

Quantity: 2

Mixing head:

The mixing head adopts floating mechanical seal. Its high shear mixing screw head can mix polyurethane and isocyanate, which has better performance. The raw materials are stirred at high speed through the mixing blade in the mixing chamber to achieve the mixing effect, so that the liquid is sprayed evenly to form the required products.

Electrical control system:

1. All controlled by single chip microcomputer.

2. PCL touch screen computer is adopted. Temperature, pressure and speed display system.

3. It has sound alarm function.

Feedback:New Australian Customer Bought Our Low Pressure Foam Machine For Big PU Block Foam With Block Mold

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for One of Hottest for Automatic Polyurethane Pu Foaming Machine - CE Mattress Pouring High Pressure PU Foaming Machine – Polyurethane, The product will supply to all over the world, such as: Japan, Bahrain, Colombia, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!