Polyurethane Cushion Insoles Three Components Low Pressure PU Foaming Machine – Polyurethane

Polyurethane Cushion Insoles Three Components Low Pressure PU Foaming Machine – Polyurethane Detail:

| Product Name: | Pu Injection Moulding Machine | Injection Output: | 26-120g/s |

|---|---|---|---|

| Foam Application: | Multi-colour Insole | Input Power: | Three-phrase Five-wire,380V 50HZ |

| Rated Power: | About 11KW | Raw Material: | Flexible Foam Polyol+Isocyanate |

| High Light: |

Insoles Low Pressure PU Foaming Machine, 120g/s pu foam making machine, 120g/s Low Pressure PU Foaming Machine |

||

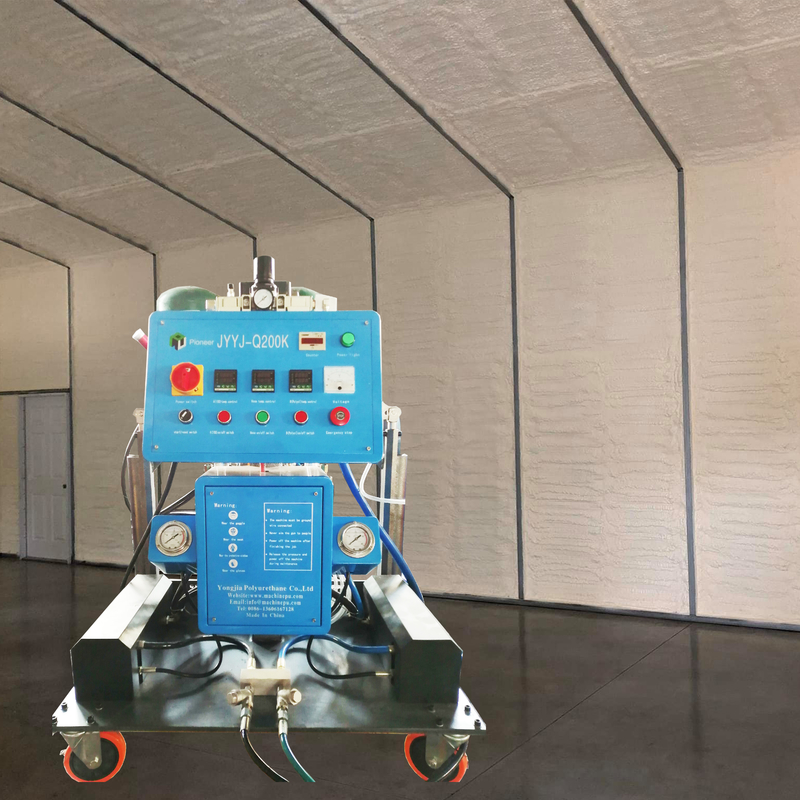

Polyurethane Soft C Shaped Memory Foam Pillow Molding Low Pressure PU Foaming Machine Product Description of polyurethane injection molding machine: SPU-RY2-120 type low pressure foaming machine is newly developed by Yongjia company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of rigid foam like imitation wood furniture, household appliances(refrigerator,freezer,water heater ), shoes manufacture, thermal insulated building materials, automobile interiors and so on. The machine owns features as high repeat injection precision, even mixing, stable performance, easy operation, high production efficiency,etc. Features of pu injection machine: 1. For sandwich type material bucket, it has good heat preservation2. The adoption of PLC touch screen human-computer interface control panel makes the machine easy to use and the operating situation was absolutely clear.3. Head connected with the operation system, easy for operation4. The adoption of new type mixing head makes the mixing even, with the characteristic of low noise, sturdy and durable.5. Boom swing length according to the requirement, multi-angle rotation, easy and fast

6. High precision pump lead to measuring accurately

7. Easy for maintenance, operation and repair.

8. Low energy consumption.

| No. | Item | Technical Parameter |

| 1 | Foam Application | Shoes (insole an out sole) |

| 2 | Applicable material viscosity (22℃) | POLYOL~3000CPS ISO ~1000MPas |

| 3 | Injection output | 26-120g/s |

| 4 | Mixing ratio range | 100:28~48 |

| 5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank Volume | 120L |

| 7 | Metering pump | A pump: JR20 Type B Pump: JR20 |

| 8 | Compressed air requirement | dry, oil free P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

| 9 | nitrogen requirement | P:0.05MPa Q:600NL/min(Customer-owned) |

| 10 | Temperature control system | Heating: 2×3.2Kw |

| 11 | input power | three-phrase five-wire,380V 50HZ |

| 12 | rated power | about 11KW |

| 13 | swing arm | Rotatable swing arm, 2.3m(length customizable) |

Applications: Polyurethane Sponges Cusp Insoles Sweat-Absorbing Shock Absorption Insoles Skid Resistance Massage Insert Pad Breathable Gel Cushion Insoles.

Anti-skidding, shock-absorbing and depressurizing.

Provide an excellent stability and cushioning effect.

Breathable insoles make you be relaxed.

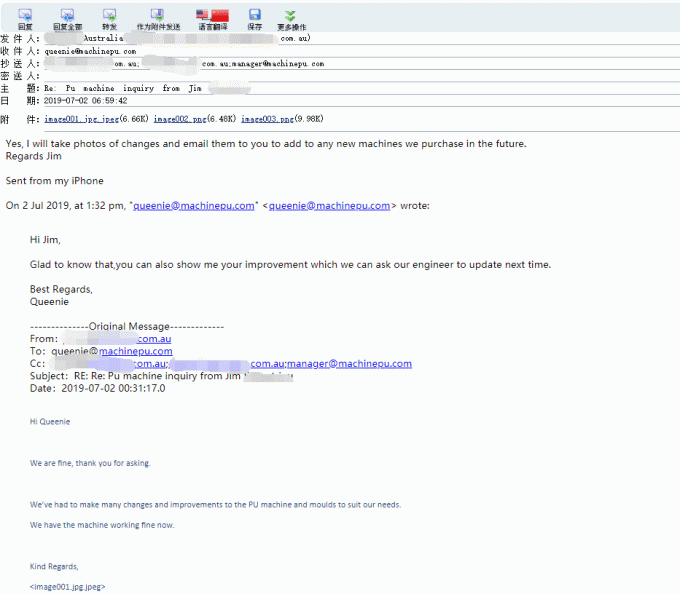

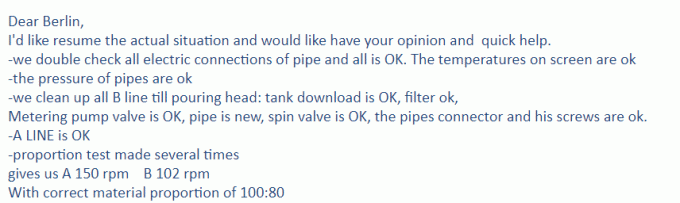

The shoe inserts pad is best for walking, prolonged standing and so on.  Feedbacks:

Feedbacks:

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Polyurethane Cushion Insoles Three Components Low Pressure PU Foaming Machine – Polyurethane, The product will supply to all over the world, such as: Thailand, Jamaica, Morocco, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.