professional factory for Shoe Making Machine - Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine – Polyurethane

professional factory for Shoe Making Machine - Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine – Polyurethane Detail:

Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine

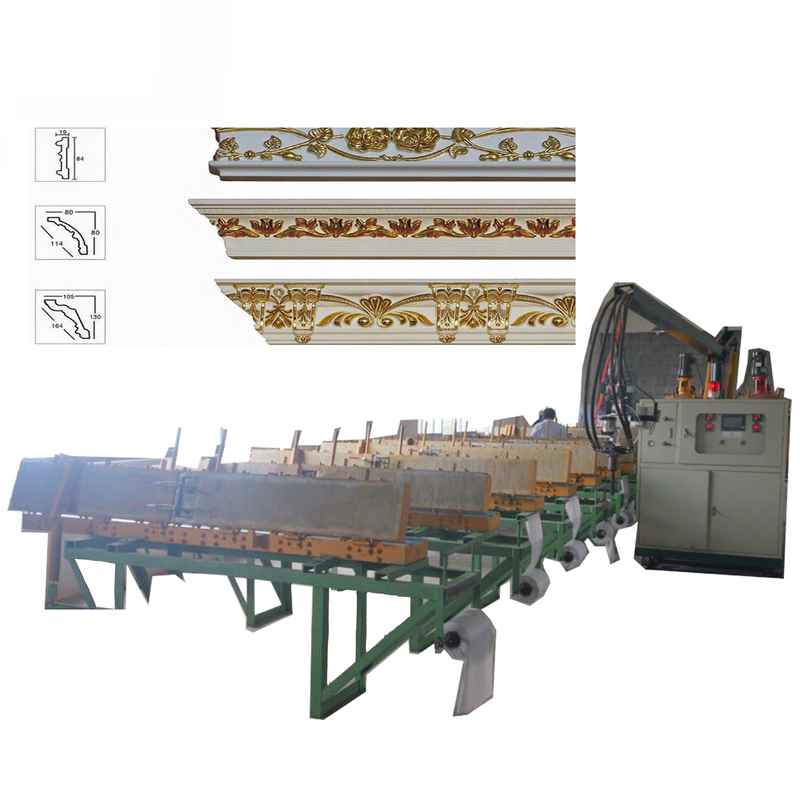

PART ONE: Disc Production Line

The disc line is used for foaming production of polyurethane shoe insole products. The equipment runs at constant speed, and the running speed and production rhythm can be adjusted. The disk is equipped with a power supply and gas source conveying system. It forms a complete foaming production line with mould temperature machine.

The equipment is composed of rotary platform, gas and electricity rotation device, pipeline device, transmission device, mold frame installation floor and electrical part, etc.

The main driving motor is controlled by variable frequency speed control, and there are many protective measures.

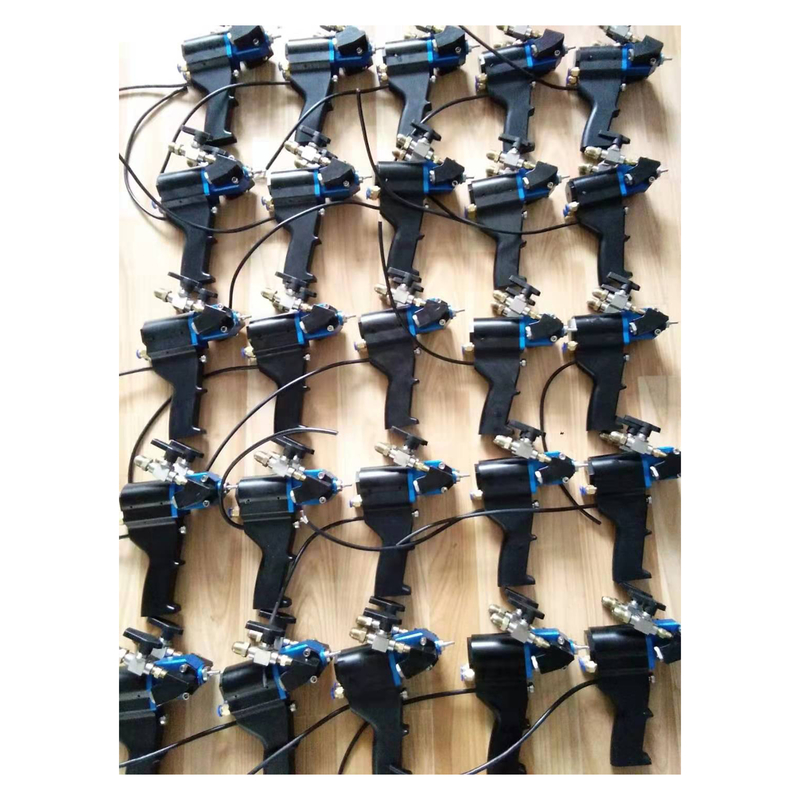

PART TWO:Two component shoe insole low pressure foaming machine

1. Metering:

High precision JR series gear metering pump (pressure-tolerant 4MPa、speed 26~130r.p.m ), make sure the metering and ration accurate and stable.

2. Electrical control system

Composed of Power switch, air switch,A.C. Contactor and whole machine engine power, heat lamp control element line,digital display temperature controller, digital display manometer, digital display tachometer, PC programmable controller(pouring time and automatic cleaning) to keep machine in good condition.manometer equipped with over pressure alarm to keep metering pump and material pipe from damage due to over pressure.

|

No. |

Item |

Technical Parameter |

|

1 |

Foam application

|

Flexible foam |

|

2 |

raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

3 |

Injection Output |

10-45g/s |

|

4 |

Mixing ratio range |

100:30~70 |

|

5 |

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

6 |

Tank Volume |

250L |

|

7 |

Metering pump |

A pump: JR-12 Type B Pump: JR-6 Type

|

|

8 |

Compressed air requirement |

dry, oil free P:0.6-0.8MPa

Q:600NL/min(Customer-owned) |

|

9 |

Temperature control system |

heat:2×3 KW |

|

10 |

Input power |

three-phrase five-wire,380V 50HZ |

|

11 |

Rated power |

about 11KW |

Application:

There’re several reasons why PU is used in footwear and some amongst them are: waterproof, lightweight, wear resistant, flexible, durable, comfortable and…

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for professional factory for Shoe Making Machine - Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine – Polyurethane, The product will supply to all over the world, such as: Mexico, Guatemala, Hongkong, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.