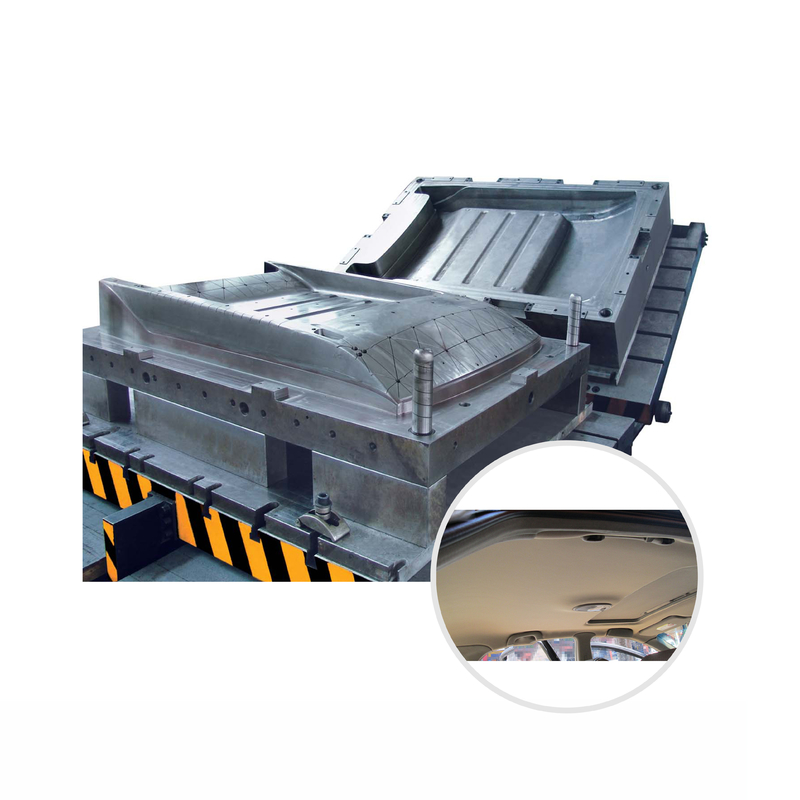

Reliable Supplier Flexible Molding Foam - Auto Interior Car Roof Liner 40s Polyurethane Foam Molds – Polyurethane

Reliable Supplier Flexible Molding Foam - Auto Interior Car Roof Liner 40s Polyurethane Foam Molds – Polyurethane Detail:

| Shaping Mode: | Plastic Injection Mould | Product Material: | Aluminium |

|---|---|---|---|

| Product: | Vehicle Mould | Product Name: | Plastic Automotive Parts Mould |

| Material: | Polyurethane PU/PP/PC/ABS | Mould Life: | 250000-300000shots |

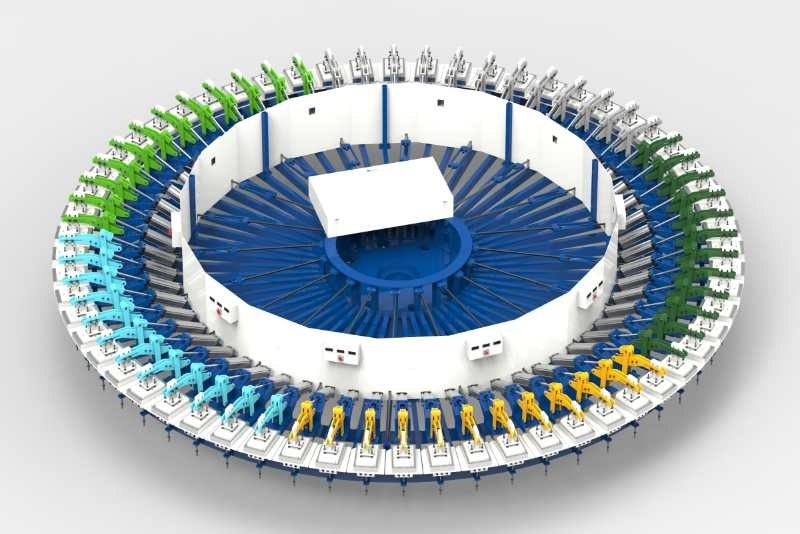

| Design Software: | UG,PROE,CAD,CATIA,SOLIDWORKS | Mould Running: | Full Automaticity |

| Cavity: | Single, Multi-Cavity | Size: | All Kinds |

| Runner: | Hot/cold | Molding Time: | 30-40s |

| Port: | Shanghai For Plastic Automotive Parts Mould | ||

| High Light: |

LKM Plastic Injection Mould, 30s Polyurethane Foam Molds, 40s Polyurethane Foam Molds |

||

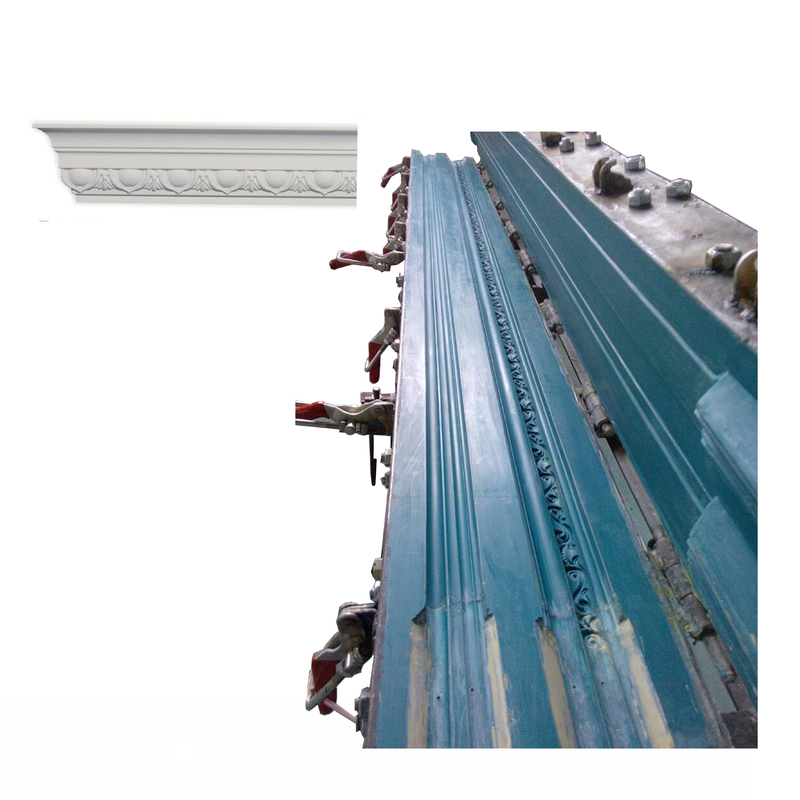

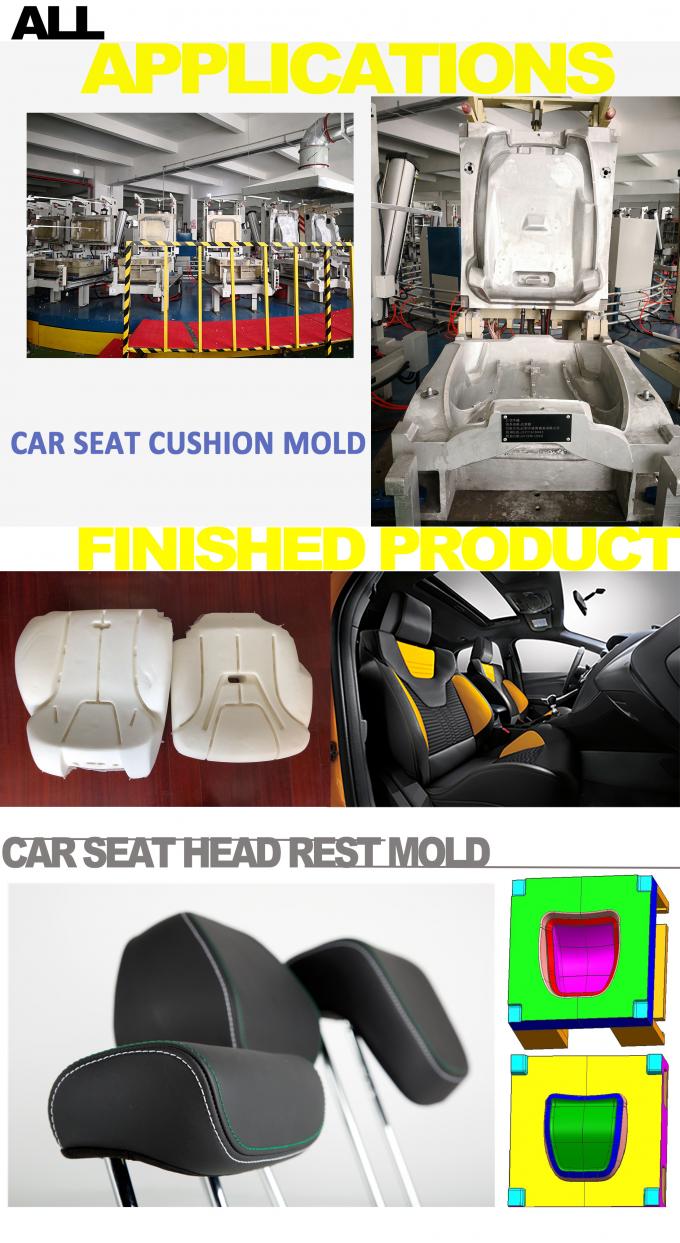

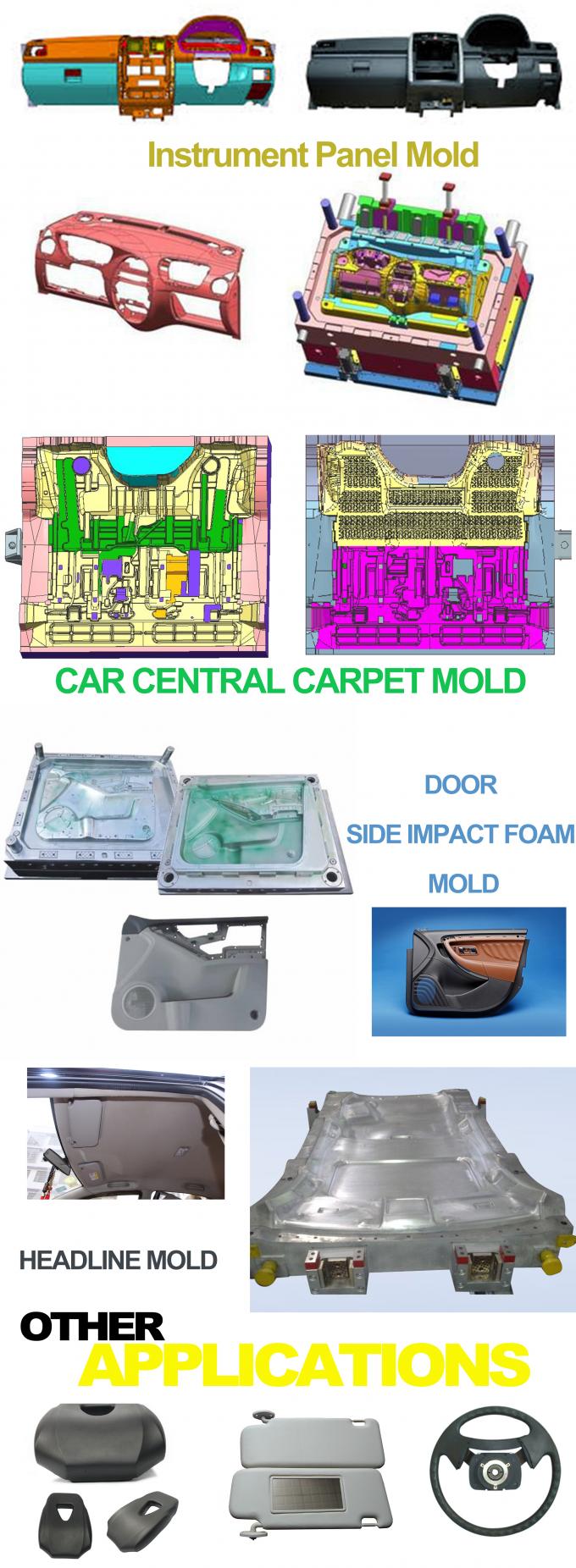

Auto Mould For PU Foam Interior Car Roof LinerAutomotive interior parts Injection Mold Mould: PU raw materials are widely used, and there are many polyurethane products in the automotive industry.Polyurethane materials can be used to make automotive seats, automotive headrests, automotive bumpers, car roofs, automotive doors, automotive steering wheels, automotive dashboards, armrests, automotive sun visors, and more.These auto parts injection molds can be customized. 1. ISO 2000 certified.

2. one-stop solution.

3. mould life, 1 million shots.

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| Mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine |

| Month Production | 100 sets/month |

| Mold Packing | standard exporting Wooden case |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Certificate | ISO 9001:2008 |

| Lead time | 25~30 days |

Our Automotive interior parts Injection Mold Mould advantange:

1) ISO9001 ts16949 and ISO14001 ENTERPRISE,ERP management system

2) Over 16 years in precision plastic mould manufacturing,collected rich experience

3) Stable technical team and frequent training system,middle management peopble are all working for over 10 year in our shop

4) Advanced maching equipment,CNC center from Sweden,Mirror EDM and JAPAN precision WIRECUT

Our professional one-stop plastic mould custom service:

1) Automotive interior parts Injection Mold Mould design service and Image design special for our customer

2) Plastic injection mold making, two shot injection mold, gas assisted mold

3) Precision plastic molding: two shot molding,precision plastic molding and gas assisted molding

4) Plastic Secondary operation, like Silk-screeking, UV, PU painting, Hot stamping, Laser engraving, Ultrasonic welding,Plating etc.

Our Team:

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Our Service:

1. Professional and patient consulting service to help you find the suitable solution.

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4. Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5. Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7. For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8. We give an accessory box for free.

9. We offer development solutions for raw material formulations.

10. If you need to visit the factory, we will arrange for personnel to pick up the airport.

Visitors and Exhibitions:

We participated in many exhibitions of polyurethane raw materials, polyurethane foam products and polyurethane PU foam machines. Our products left a very good impression to everyone at the show, some customers even placed orders on the spot.

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Reliable Supplier Flexible Molding Foam - Auto Interior Car Roof Liner 40s Polyurethane Foam Molds – Polyurethane, The product will supply to all over the world, such as: belarus, Juventus, Belize, We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.