Rigid Foam Cornice Moulding 58HRC Plastic Injection Mold – Polyurethane

Rigid Foam Cornice Moulding 58HRC Plastic Injection Mold – Polyurethane Detail:

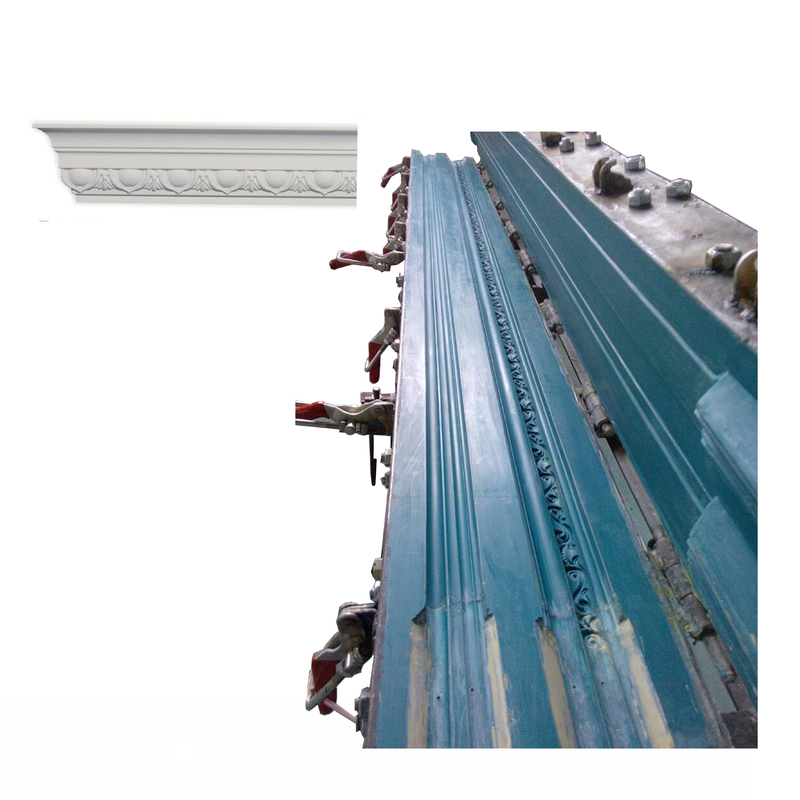

PU Polyurethane Plastic Custom Mould For Rigid Foam Cornice Moulding

PU cornice mould:

polyurethane cornice is a molded product. It is made by mixing two foams together that expand inside of the mold to form a product.

Characterist of pu cornice:

1. Low cost: the surface painting is finished and installation time is very short; can be planed, sawed, nailed and guled by yourself, 80% cost saved than using wood and concrete.

2. Light weight: good resilience and tenacity, light and hard.

3. Entirety: classic, elegant and uniform.

4. Fire-proof: reach the standard of no combustion, uncombustion – supporting and unburning.

5. Water – proof: no moisture – absorbing, water – permeation and mild – ew – arising.

6. Anti- erosion: resist acid and alkali.

7. Environment protection: using polyester as raw material to avoid lumbering sites suitable: House, Restaurant, Hotel, Salon, Club etc.

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| Mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine |

| Month Production | 100 sets/month |

| Mold Packing | standard exporting Wooden case |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Certificate | ISO 9001:2008 |

| Lead time | 25~30 days |

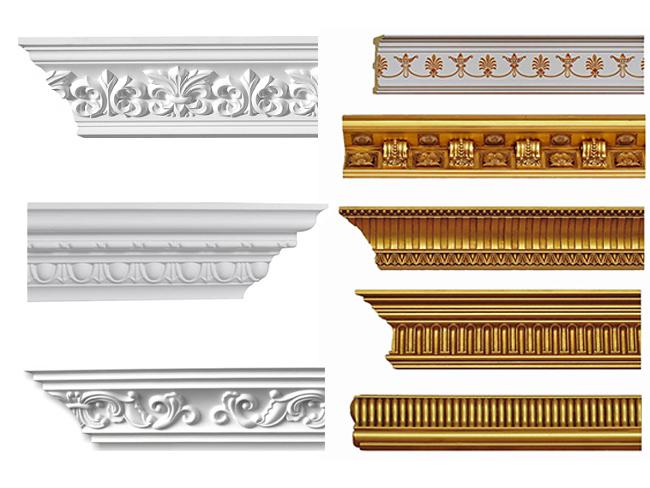

A cornice is a type of molding which runs along the top lengths of your interior walls, which sits in the join between the walls and the ceiling. Cornices are also commonly known as “coving”, or “crown, bed or cove molding”.

Cornice molding is placed on the top, where the wall meets the ceiling. Even a single piece of cornice molding will add an entirely new dimension to a room. Cornice molding creates s decorative transition between walls and ceiling and works especially well in rooms with high ceilings.

Our Plastic mould advantange:

1)ISO9001 ts16949 and ISO14001 ENTERPRISE,ERP management system

2)Over 16 years in precision plastic mould manufacturing,collected rich experience

3)Stable technical team and frequent training system,middle management peopble are all working for over 10 year in our shop

4)Advanced maching equipment,CNC center from Sweden,Mirror EDM and JAPAN precision WIRECUT shots

Our professional one-stop plastic mould custom service:

1)Mold design service and Image design special for our customer

2)Plastic injection mold making,two shot injection mold,gas assisted mold

3)Precision plastic molding:two shot molding,precision plastic molding and gas assisted molding

4) Plastic Secondary operation,like Silk-screeking,UV,PU painting,Hot stamping,Laser engraving,Ultrasonic welding,Plating etc. PU Cornice Mould Photos

Application:

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Rigid Foam Cornice Moulding 58HRC Plastic Injection Mold – Polyurethane, The product will supply to all over the world, such as: Berlin, San Diego, Czech republic, Adhering to the management tenet of "Managing Sincerely, Winning by Quality", we try our best to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.