Bottom price Freezer Production Line - PU Foam Shoe Sole Pouring Machine Safety Shoe Making Equipment Machinery – Polyurethane

Bottom price Freezer Production Line - PU Foam Shoe Sole Pouring Machine Safety Shoe Making Equipment Machinery – Polyurethane Detail:

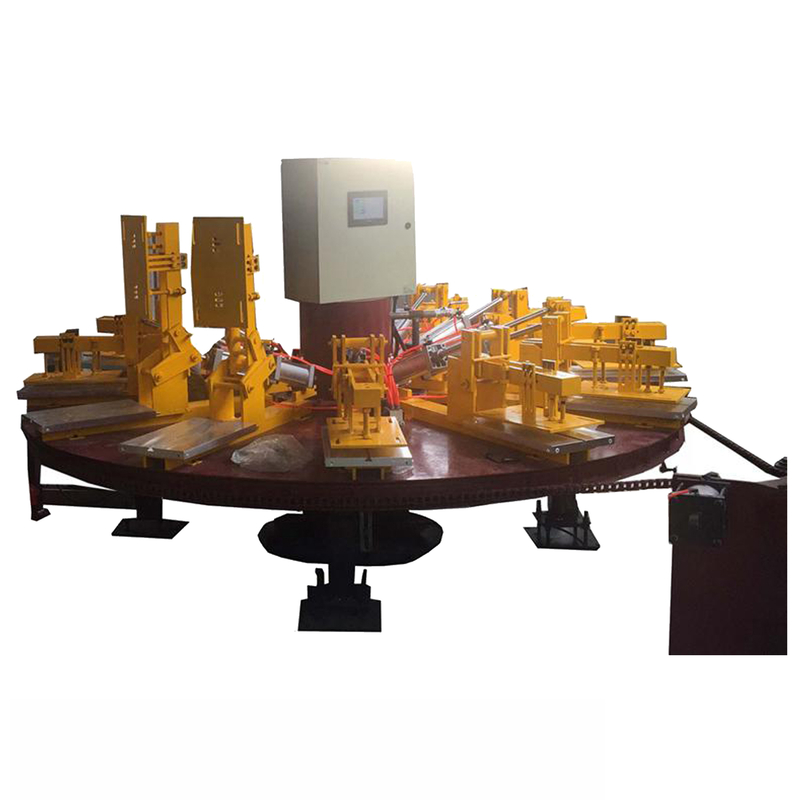

PU Foam Shoe Sole Pouring Machine Safety Shoe Making Equipment Machinery

Introduction:

Annular automatic insole and sole production line is an ideal equipment based on our company’s independent research and development, which can save labor cost, improve production efficiency and automatic degree, also possess the characteristics of stable performance, accurate metering, high precision positioning, automatic position identifying.

| Bucket | Metering Pump | Metering Pump Motor Power | Spit Out Quality | Total Power |

| A.120L | JR9 | 0.75kw | 10-40g/s | 8.5kw |

| B.120L | JR3.6 | 0.55kw | ||

| S.2L | JR0.3 | 0.2kw |

Main Parts of the pu shoes making machine:

Low pressure foaming machine is newly developed by Yongjia company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of rigid foam like imitation wood furniture, household appliances(refrigerator,freezer,water heater ), shoes manufacture, thermal insulated building materials, automobile interiors and so on. The machine owns features as high repeat injection precision, even mixing, stable performance, easy operation, high production efficiency,etc.

Semi-pneumatic production line is a versatile mold carrying lines for high-volume production of PU shoes, the diameter of the entire semicircle production line is 7 meters, with water circulation mold heating system and pneumatic control system. will improve product quality, reduce labor intensity and improve production efficiency. Which is very simple to learn and easy to operate.

Application:

Polyurethane soles, popularly known as PU soles, are made from a new kind of organic polymer material. It has been hailed as the fifth big plastic, and is in the process of revolutionizing the shoe industry.

PU sole has lower density than other soles along with a soft texture and high elasticity. This makes it perfect for foot comfort. It not only provides great wear and tear resistance but also has good bending resistance and high hardness along with great shock absorption.

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Bottom price Freezer Production Line - PU Foam Shoe Sole Pouring Machine Safety Shoe Making Equipment Machinery – Polyurethane, The product will supply to all over the world, such as: Armenia, Uzbekistan, Adelaide, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!