Discount Price Wall Panel Roll Forming Machine - Discontinuous Polyurethane Foam Insulation Panels Cold Rooms Machine Production Line – Polyurethane

Discount Price Wall Panel Roll Forming Machine - Discontinuous Polyurethane Foam Insulation Panels Cold Rooms Machine Production Line – Polyurethane Detail:

Discontinuous Polyurethane Foam Insulation Panels Cold Rooms Machine Production Line

Product Feature:

PU PIR PUR PUF Sandwich panel machine includes uncoiling system, film covering and cutting system, roll forming machine, preheating oven, high pressure foaming system, double belt conveyor, double belt heating device, cutting system, etc….The sandwich panel press machine adopts gantry lift-draw type, locates directly without any foundation. 2+2 type saves much time for panel preparation and discharge time which increase times of efficiency. The polyurethane foaming process of Yongjia can meet various needs of the construction industry.

PU/PIR/PUR/PUF Sandwich Panel Machine / Sandwich Panel Production Line / Discontinuous PU Sandwich Panel Machine can produce Polyurethane (PU) foam panel with high density, excellent quality, any sizes for multifunctional used. Polyurethane composite board is widely used in metallurgy, petroleum, automobile, mineral processing, water conservancy and other aspects of materials, with strong elastic strength, excellent wear resistance and other advantages.

| Production line shape size | 48000*8000mm | highest temperature | 70℃ |

| products specifications | Width:1200mm Thickness:15~100mm |

Minimun cut length | 1200mm |

| Production speed | 3-8 m/min | Diagonal accuracy | ±2mm |

| Weight | 40T | total power | 120kw |

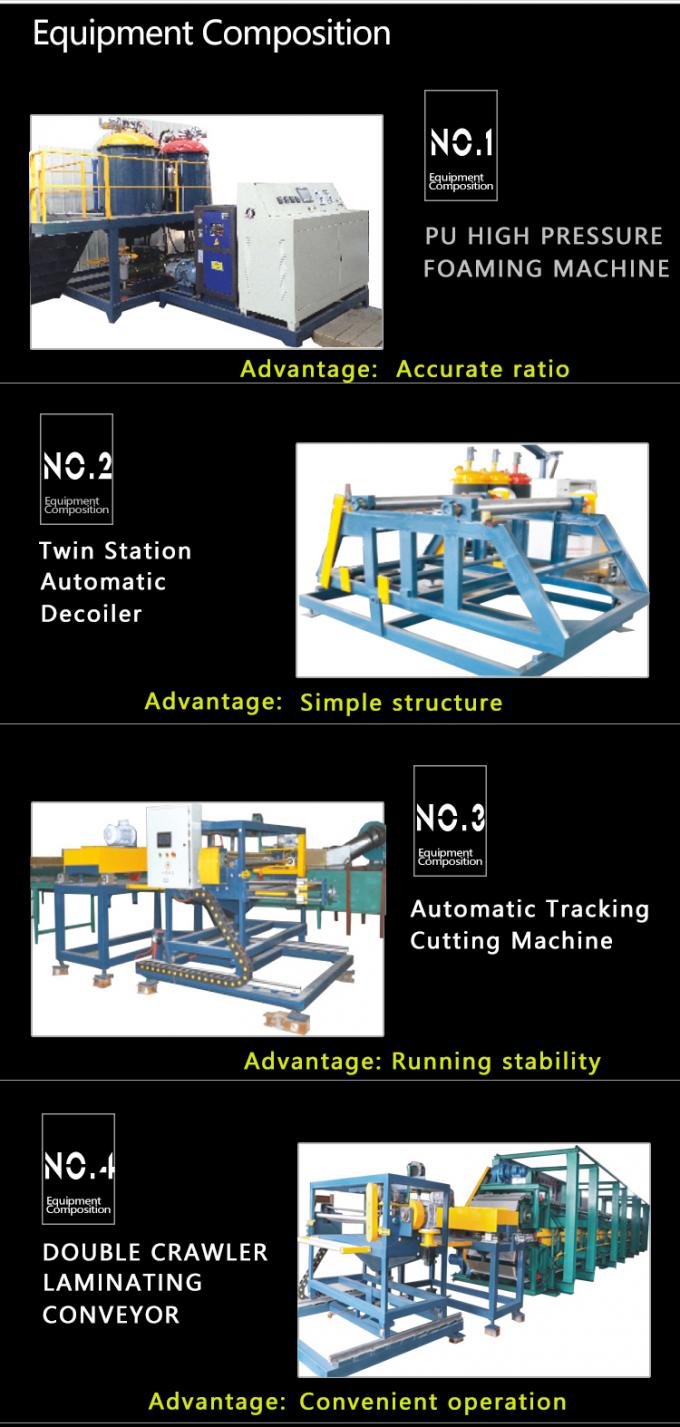

Equipment Compostion

This production line consists of two sets of new type double head uncoiler,one set of preheatingdevice,one PU high pressure foaming machine,one mobile casting machine,one set of side paperdevice,laminating conveyor,one set(electricity,steam)heated air circulation device,one band center slitting trimming machine,one automatic tracking cutting machine,mill frame,etc.

Our Factory:

Yongjia is one of the leading sandwich panel machine manufacturers in China who has been specialized in providing high-quality PIR/PU sandwich panel production line. The PU sandwich panel lines were exported to many countries, such as Poland, Brazil, Jordan, Kuwait, Saudi Arabia, Tunisia, and so on. The production line performance has got unanimous

approval and favorable comment from domestic and international customers. Feel free to contact us for PIR/PU sandwich panel production line price!

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Discount Price Wall Panel Roll Forming Machine - Discontinuous Polyurethane Foam Insulation Panels Cold Rooms Machine Production Line – Polyurethane, The product will supply to all over the world, such as: Palestine, Hungary, Greenland, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!