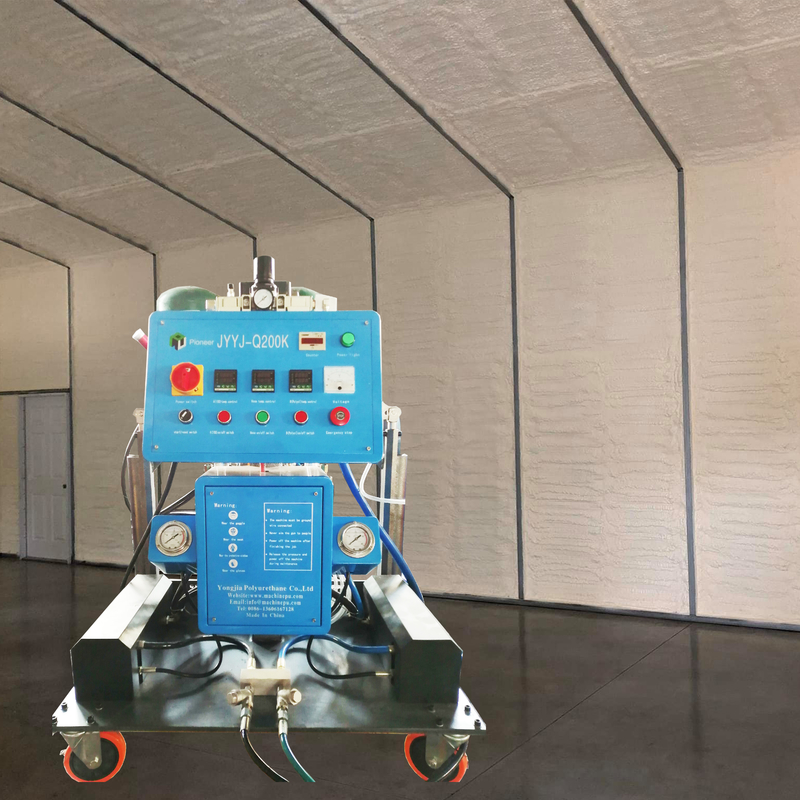

Factory directly supply Machine Polyurethane - Pneumatic PU Foam Spray Insulation Injecting Equipment Polyurethane Spray Foam Machine – Polyurethane

Factory directly supply Machine Polyurethane - Pneumatic PU Foam Spray Insulation Injecting Equipment Polyurethane Spray Foam Machine – Polyurethane Detail:

| Name: | Pu Foam Spray Machine | Material: | Polyurethane Or Polyurea |

|---|---|---|---|

| POWER SOURCE: | 3-phase 4-wires 380V 50HZ | HEATING POWER (KW): | 11 |

| AIR SOURCE (min): | 0.5~0.8Mpa≥0.9m3 | MAXIMUM OUTPUT (Mpa): | 11 |

| Matrial A:B=: | 1:1~1:2 (adjusted) | ||

| High Light: |

Pneumatic PU Foam Spray machine, Pneumatic Polyurethane Spray Foam Machine, Polyurea PU Foam Injection machine |

||

Pneumatic PU Foam Spray Insulation Injecting Equipment Polyurethane Spray Foam Machine

Main Features of spray foam insulation Machine:

1. pneumatic supercharging device, with small volume, light weight, low failure rate, simple operation, easy operation and other great features;2. adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;3. minimizing spraying congestion with multi-feedstock device;4. multi-leakage protection system to protect the safety of the operator;5. equipped with emergency switch system, help operator deal with emergencies rapidly;6. great 380V heating system enables rapid warming of raw materials to the best state, speeds up normal operation progress;7. digital counting system can understand original consumption timely;8. humanized design with equipment operation panel, super easy to get the hang of it;9. the latest spraying gun has great features like small volume, light weight, low failure rate, etc;10. lifting pump adopts big change ratio method, the winter also can easily feed raw materials high viscosity.

| SPECIFICATIONS FOR JYYJ-Q200(K) PU Spray Machine | ||

| Parameter | Raw material | polyurethane |

| Features | A:B ratio can be adjusted(1:1~1:2) | |

| Power source | 3-phase 4-wires 380V 50HZ | |

| Heating power | 11KW | |

| Driven mode | pneumatic | |

| Air source | 0.5-0.8 MPa ≥0.9m³/min | |

| Raw output | 2-12 kg/min | |

| Maximum output pressure | 11MPA | |

| Poly and ISO material output ratio | 1:1~1:2 (adjusted) | |

| Spare parts | Spray gun | 1 Set |

| Heating hose | 15-120 meters | |

| Spray gun connector | 2 m | |

| Accessories box | 1 | |

| Instruction book | 1 | |

Applications 1. Insulation & Coating: external wall insulation, internal wall insulation, roof, cold storage, ship cabin, cargo containers,trucks, refrigerated trucks,tank, etc.2. Casting: solar water heaters,tank insulation, cabin, insulation board, security doors, refrigerators, pipes, road construction, packaging, road construction, wall insulation, etc.

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Factory directly supply Machine Polyurethane - Pneumatic PU Foam Spray Insulation Injecting Equipment Polyurethane Spray Foam Machine – Polyurethane, The product will supply to all over the world, such as: Nigeria, Estonia, Juventus, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.