Factory making Foam Foam Machine - Memory Foam Pillow Making Machine Turntable Polyurethane Foam Production Line – Polyurethane

Factory making Foam Foam Machine - Memory Foam Pillow Making Machine Turntable Polyurethane Foam Production Line – Polyurethane Detail:

| Processing Type: | Foaming Machine, Mixing Head Inject Raw Material | Product Type: | Foam Net, Production Line |

|---|---|---|---|

| Machine Type: | Foam Machine | Key Selling Points: | High-accuracy |

| Name: | Cushion Filling Machine | Raw Material: | PU |

| Usage: | Production Of Polyurethane Memory Pillow | Other Name: | Memory Foam Cooling Pillow |

| High Light: |

Memory Foam Pillow Making Machine, Turntable Polyurethane Foam Production Line, 120L Polyurethane Foam Production Line |

||

Memory Foam Pillow Making Machine With PU Turntable Production Line Polyurethane Foam Production Line Product Description of memory foam pillow machine: The equipment consists of a polyurethane foaming machine (low-pressure foaming machine or high-pressure foaming machine) and a production line. Customized production can be carried out according to the nature and requirements of customers' products. Our SPU-R2A63-A40 type low pressure foaming machine is newly developed by Yongjia company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of automotive parts, automotive interior, toys, memory pillow and other kinds of flexible foams like integral skin, high resilience and slow rebound , etc. This machine has high repeat injection precision, even mixing, stable performance, easy operation, and high production efficiency, etc.

| No. | Item | Technical Parameter |

| 1 | Foam application | Flexible foam |

| 2 | Raw material viscosity(22℃) | POL ~3000CPS ISO ~1000MPas |

| 3 | Injection Output | 155.8-623.3g/s |

| 4 | Mixing ratio range | 100:28~50 |

| 5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank Volume | 120L |

| 7 | Metering pump | A pump: GPA3-63 Type B Pump: GPA3-25 Type |

| 8 | Compressed air requirement | dry, oil free P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

| 9 | Nitrogen requirement | P:0.05MPa Q:600NL/min(Customer-owned) |

| 10 | Temperature control system | heat:2×3.2kW |

| 11 | Input power | three-phrase five-wire,415V 50HZ |

| 12 | Rated power | about 13KW |

Basic description: The twenty station foaming line is arranged in a planar ring structure, and the frequency conversion motor is used to drive the whole motion of the wire body through a variable speed turbine box. The speed of the transmission line can be adjusted by frequency conversion, which is convenient to adjust the production rhythm. The power supply adopts the sliding contact line is introduced, the external source of central gas supply, introduced into each frame body through the joint line. In order to facilitate the replacement of mold and maintenance, the temperature control water, cable and compressed air between the various positions of the mold and the connection of the fast plug connection.It is Safe and reliable with the mold of airbag to open &close. Main components and parameter specification: Material system consists of material tank, filter tank, metering pump, material pipe, infusion head, cleaning tank. Double interlining heating material tank with insulation outer layer, heat rapidly, low energy consumption. Liner, upper and low head all adopt stainless 304 material, upper head is precision machinery sealing equipped to make sure the air tight agitation. Material in the tank flow to the filter tank Φ100X200 by discharge valve, after filtering, flow to the metering pump. Sealing flat cover on the tank, inner tank with a filter net, tank body with a feeding and discharge port, there is a discharge ball valve below the tank. Application: PU polyurethane foaming machine can be used in the manufacture of PU pillows.This polyurethane material pillow is soft and comfortable, has the advantages of decompression, slow rebound, good air permeability, etc. It is a high-tech material.The size and shape of the PU pillow can be customized.

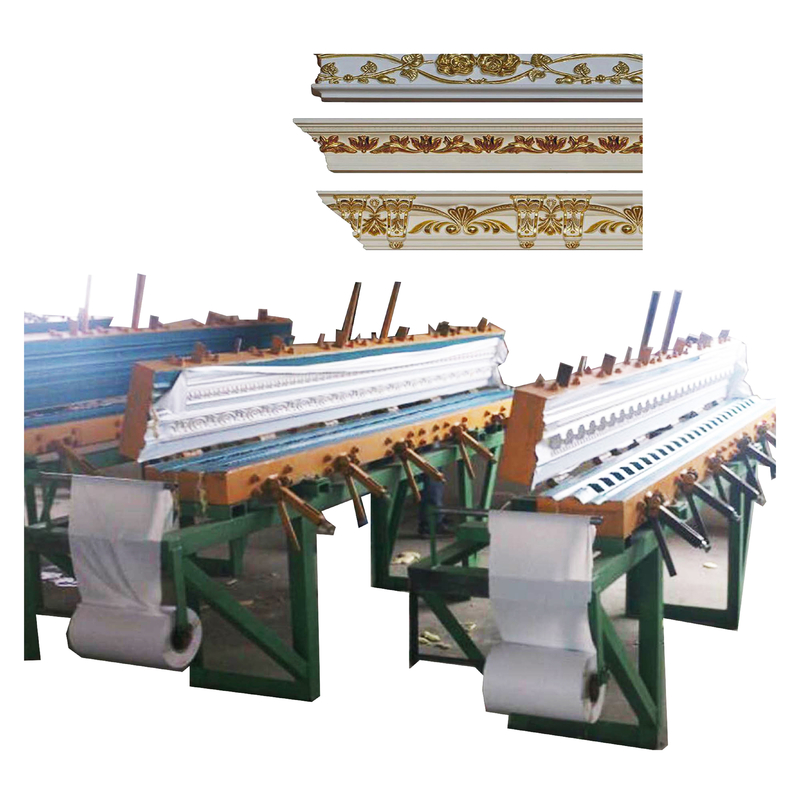

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of Factory making Foam Foam Machine - Memory Foam Pillow Making Machine Turntable Polyurethane Foam Production Line – Polyurethane, The product will supply to all over the world, such as: Cyprus, Netherlands, Tajikistan, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!