Factory wholesale Coldroom Parts - Refrigerator Shell Injection Isocyanate PU Foam Molds – Polyurethane

Factory wholesale Coldroom Parts - Refrigerator Shell Injection Isocyanate PU Foam Molds – Polyurethane Detail:

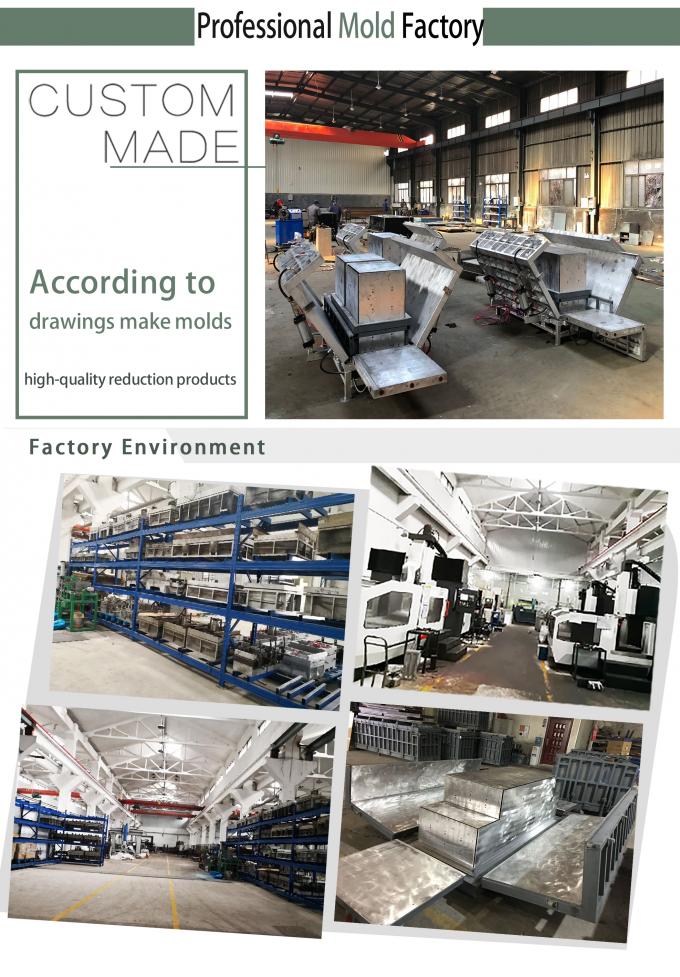

China Directly Mould Factory Make Plastic Fridge Part Mold,Refrigerator Shell Injection Mould

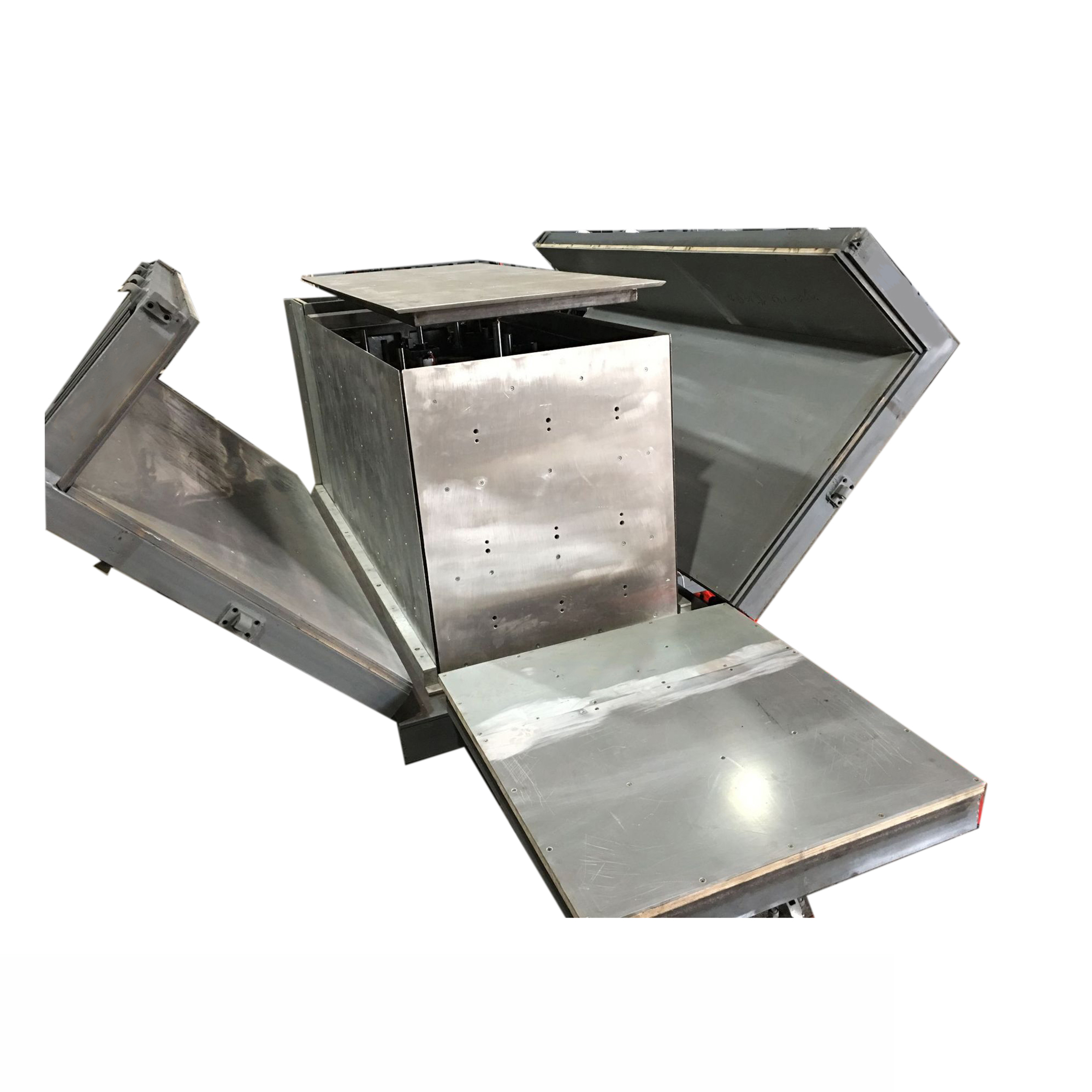

Refrigerator And Freezer Cabinet Injection Mold Mould:

Polyurethanes are ideal for the insulation of refrigerating appliances and have major advantages as they are:

excellent insulators

structurally strong thanks to the rigidity of the foam and adhesion of external skins (plastic and metal)

the most cost-effective manufacturing solution, with multiple operations combined into one

effective in confined spaces, allowing the maximum amount of food to be stored

safe

robust and strong

very light, thus reducing transportation costs

affordable, keeping the costs of refrigerators and freezers down

We can supply mold customize service in many applications, like:

Heating dryer & freezer

Polyurethane foam domestic refrigerators/freezers

Commercial/industrial refrigerators

Panels for walk-in cold rooms and ice storage

Functional components

Ventilation products

Water treatment structures

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| Mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine |

| Month Production | 100 sets/month |

| Mold Packing | standard exporting Wooden case |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Certificate | ISO 9001:2008 |

| Lead time | 25~30 days |

Our Refrigerator and Freezer Cabinet Injection Mold Mould advantange:

1)ISO9001 ts16949 and ISO14001 ENTERPRISE,ERP management system

2)Over 16 years in precision plastic mould manufacturing,collected rich experience

3)Stable technical team and frequent training system,middle management peopble are all working for over 10 year in our shop

4)Advanced maching equipment,CNC center from Sweden,Mirror EDM and JAPAN precision WIRECUT

Our professional one-stop plastic mould custom service:

1)Refrigerator and freezer cabinet Injection Mold Mould design service and Image design special for our customer

2)Plastic injection mold making,two shot injection mold,gas assisted mold

3)Precision plastic molding:two shot molding,precision plastic molding and gas assisted molding

4) Plastic Secondary operation,like Silk-screeking,UV,PU painting,Hot stamping,Laser engraving,Ultrasonic welding,Plating etc.

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company’s products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

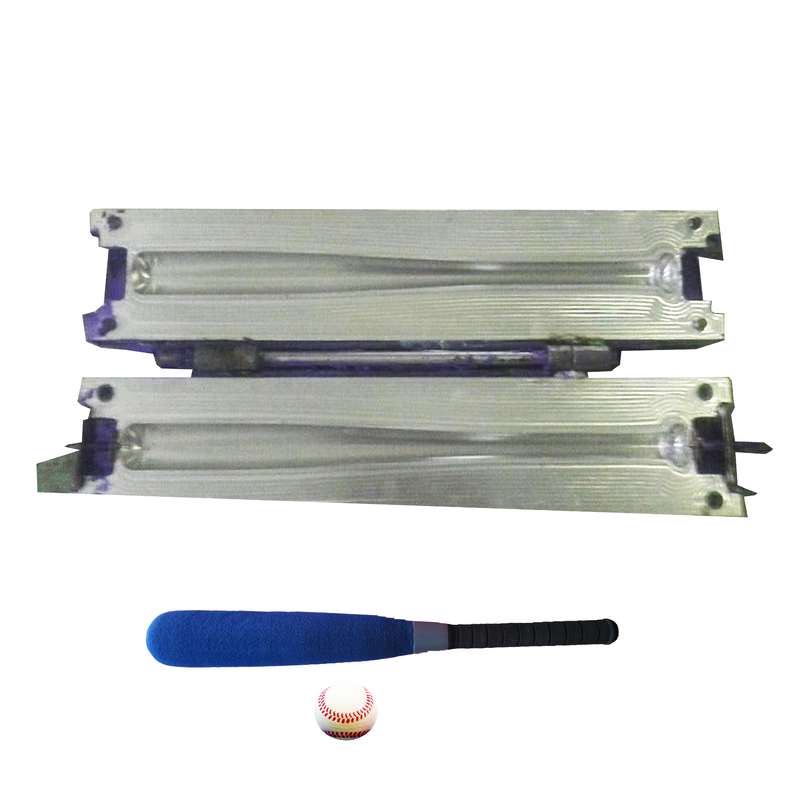

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Factory wholesale Coldroom Parts - Refrigerator Shell Injection Isocyanate PU Foam Molds – Polyurethane, The product will supply to all over the world, such as: Nigeria, belarus, Egypt, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!