Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine – Polyurethane

Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine – Polyurethane Detail:

Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine

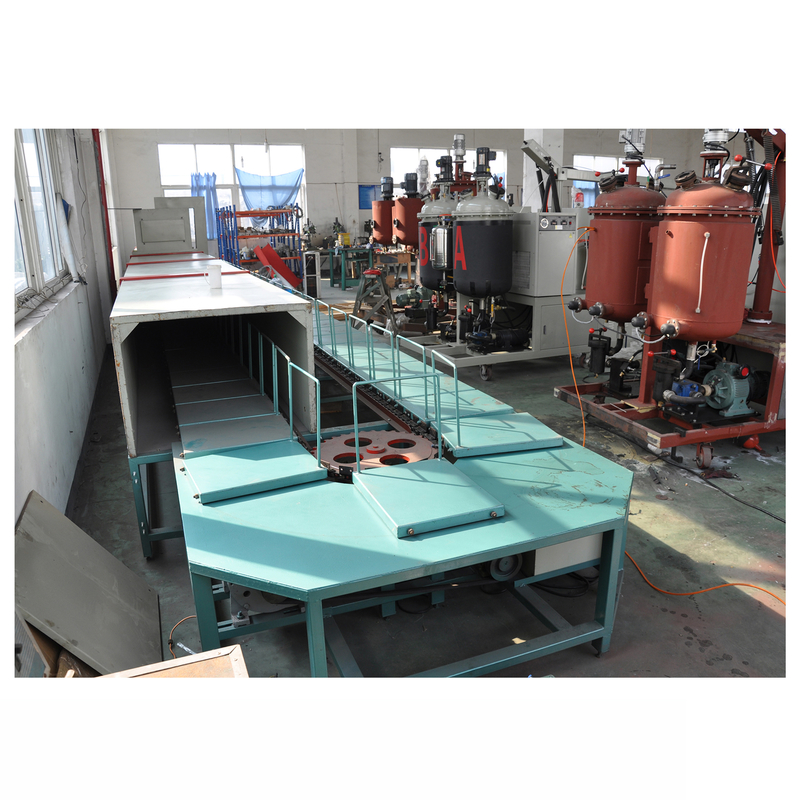

PART ONE: Disc Production Line

The disc line is used for foaming production of polyurethane shoe insole products. The equipment runs at constant speed, and the running speed and production rhythm can be adjusted. The disk is equipped with a power supply and gas source conveying system. It forms a complete foaming production line with mould temperature machine.

The equipment is composed of rotary platform, gas and electricity rotation device, pipeline device, transmission device, mold frame installation floor and electrical part, etc.

The main driving motor is controlled by variable frequency speed control, and there are many protective measures.

PART TWO:Two component shoe insole low pressure foaming machine

1. Metering:

High precision JR series gear metering pump (pressure-tolerant 4MPa、speed 26~130r.p.m ), make sure the metering and ration accurate and stable.

2. Electrical control system

Composed of Power switch, air switch,A.C. Contactor and whole machine engine power, heat lamp control element line,digital display temperature controller, digital display manometer, digital display tachometer, PC programmable controller(pouring time and automatic cleaning) to keep machine in good condition.manometer equipped with over pressure alarm to keep metering pump and material pipe from damage due to over pressure.

|

No. |

Item |

Technical Parameter |

|

1 |

Foam application

|

Flexible foam |

|

2 |

raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

3 |

Injection Output |

10-45g/s |

|

4 |

Mixing ratio range |

100:30~70 |

|

5 |

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

6 |

Tank Volume |

250L |

|

7 |

Metering pump |

A pump: JR-12 Type B Pump: JR-6 Type

|

|

8 |

Compressed air requirement |

dry, oil free P:0.6-0.8MPa

Q:600NL/min(Customer-owned) |

|

9 |

Temperature control system |

heat:2×3 KW |

|

10 |

Input power |

three-phrase five-wire,380V 50HZ |

|

11 |

Rated power |

about 11KW |

Application:

There’re several reasons why PU is used in footwear and some amongst them are: waterproof, lightweight, wear resistant, flexible, durable, comfortable and…

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for Footwear Shoe Sole Making Machine Auto Rubber PU Sole Foam Molding Machine – Polyurethane, The product will supply to all over the world, such as: Netherlands, Hongkong, Lesotho, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.