Hot-selling Toilet Seat Making Machine - Bed Head Polyurethane 160g/s Low Pressure Foaming Machine – Polyurethane

Hot-selling Toilet Seat Making Machine - Bed Head Polyurethane 160g/s Low Pressure Foaming Machine – Polyurethane Detail:

| Condition: | New | Key Selling Points: | Automatic |

|---|---|---|---|

| Product Type: | Foam Net | Machine Type: | Injection Machine |

| Voltage: | 380V | Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm |

| Power (kW): | 168kW | Weight (KG): | 1200 KG |

| Warranty: | 1 YEAR | After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Local Service Location: | Turkey, Pakistan, India |

| Showroom Location: | Turkey, Pakistan, India | Applicable Industries: | Manufacturing Plant |

| Marketing Type: | New Product 2020 | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 6 Months |

| Core Components: | Motor | Name: | Polyurethane Low Pressure Foaming Equipment |

| Filter: | Self-cleaning Filter | Material Feeding: | Automatic Feeding System |

| Control System: | PLC | Metering Pump: | Precise Metering |

| Foam Type: | Rigid Foam | Tank Volume: | 250L |

| Power: | Three-phase Five-wire 380V | Port: | Ningbo For Polyurethane Low Pressure Foaming Equipment |

| High Light: |

160g/s PU foam injection machine, 160g/s low pressure foaming machine, 250L low pressure foaming machine |

||

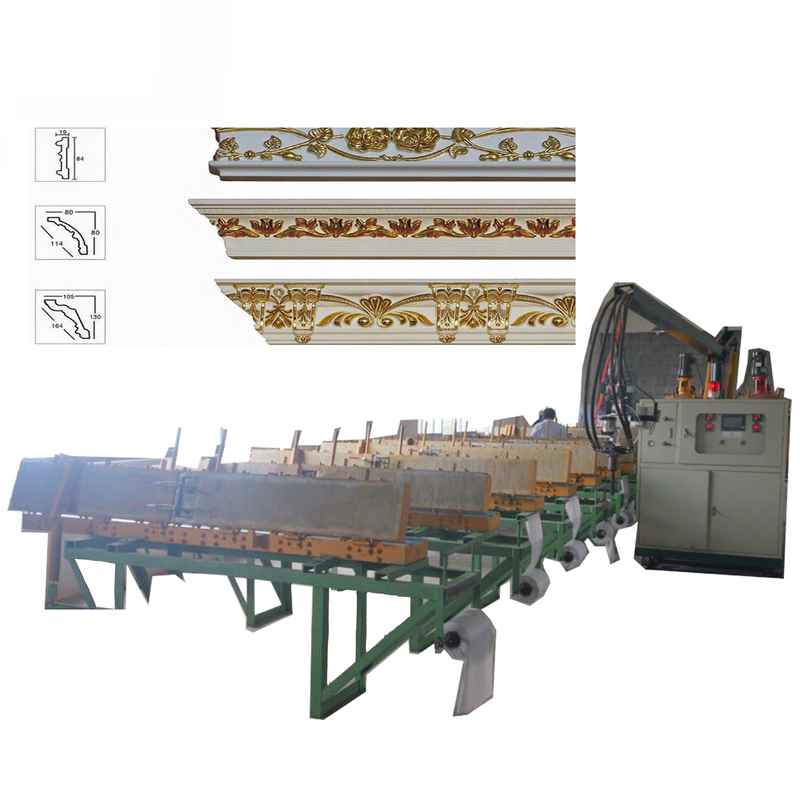

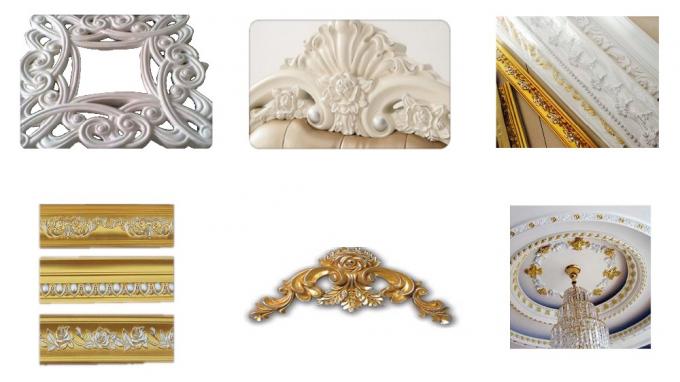

Polyurethane Low Pressure Foaming Equipment PU Injection Machine For Bed Head Application: Suitable for the other production of polyurethane pillow, steering wheel, bumper, self skin, high reilience, slow rebound, toys, fitness equipment, insulation layer, bicycle cushion, rigid foam, cold storage panel, medical equipment, elastomer, shoe sole, ect… Decoration Parts And Imitation Wood Furniture ProductPolyurethane foam can be used to make decorative parts such as crown molding. Can also be used for imitation wood furniture and

photo frames. Product Description: Polyurethane low-pressure foaming machine is widely used in multi-mode continuous production of rigid and semi-rigid polyurethane products, such as: petrochemical equipment, directly buried pipelines, cold storage, water tanks, meters and other thermal insulation and sound insulation equipment craft products.

| No. | Item | Technical parameter |

| 1 | Foam application | Flexible Foam 3D Wall Panel |

| 2 | Raw material viscosity(22℃) | POL ~3000CPS ISO ~1000MPas |

| 3 | Injection flow rate | 160-900g/s |

| 4 | Mixing ratio range | 100:50~150 |

| 5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank Volume | 280L |

| 7 | Input power | Three-phase five-wire 380V 50HZ |

| 8 | Rated power | About 12KW |

| 9 | Swing arm | Rotatable 90°swing arm, 2.3m (length customizable) |

| 10 | Volume | 4100(L)*1300(W)*2300(H)mm, swing arm included |

| 11 | Color( customizable) | Cream-colored/orange/deep sea blue |

| 12 | Weight | About 1200Kg |

Features of Low Pressure Foam Machine: 1. Accurate measurement: high-precision low-speed gear pump, error ≤0.5%.

2. Uniform mixing: Multi-tooth high-shear mixing head is used, with reliable performance.

3. Pouring head: special mechanical seal is used to prevent air leakage and material pouring.

4. The material temperature is stable: the material tank adopts its own heating temperature control system, and the temperature control is determined, and the error is ≤2℃

5. The whole machine adopts 7-inch touch screen and PLC module control, which can be poured regularly and quantitatively and can be automatically cleaned by air flushing.

Raw Material Formula Solution Support:

We have our own technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material formulas like polyurethane rigid foam, PU flexible foam, polyurethane integral skin foam and polyurea that meet all customer' s requirements.  Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Exhibitions and Visitors:

FAQ: 1. Are you factory or trading company?

FAQ: 1. Are you factory or trading company?

We are professional factory in PU industry with more than 10 years experience, covering high pressure pouring machine,low pressure foaming machine, pu spraying foam machine,pu elastomer casting machine and production line.

2. Where is your factory ?

Our Factory is located in Wuxi city, Jiangsu Province.

3. How can I get your factory?

By air: You can take a plan to WUXI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

4. Do you provide pick-up service?

Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.

5. What is the PU raw material used with this polyurethane/polyurea foam casting machine?

Polyurethane which has two components polyol and isocyanate(poly and iso/mdi). Polyurea also can be used which helps to waterproofing and Anticorrosion and rust prevention. Polyurethane can be divided into two kinds, flexible foam and rigid foam. And flexible foam or rigid foam also has two kinds, open cell foam and closed cell foam.

6. If I need to develop a special PU raw material formula solution based on my product, can you provide it?

Yes, we can. We have technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material soluation like polyurethane rigid foam, polyurethane flexible foam, polyurethane integral skin foam and polyurea to meet customer' s requirements.

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Hot-selling Toilet Seat Making Machine - Bed Head Polyurethane 160g/s Low Pressure Foaming Machine – Polyurethane, The product will supply to all over the world, such as: Porto, Brisbane, Mozambique, We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.