Leading Manufacturer for Puf Panel Machine - CE Certificated PU Sandwich Panel Making Machine Line for Coldroom Wall Panel Production – Polyurethane

Leading Manufacturer for Puf Panel Machine - CE Certificated PU Sandwich Panel Making Machine Line for Coldroom Wall Panel Production – Polyurethane Detail:

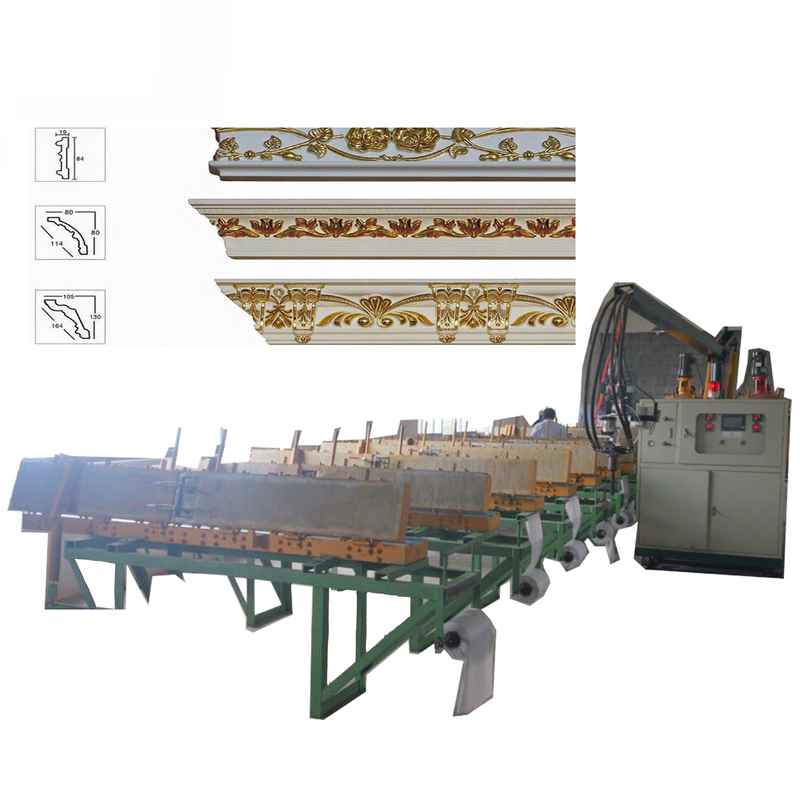

CE Certificated PU Sandwich Panel Making Machine Line for Coldroom Wall Panel Production

Product Feature:

Rigid polyurethane has low thermal conductivity and good thermal performance. When the rigid polyurethane capacity is 35~40kg/m3, the thermal conductivity is only 0.018g~0.023w/ (m. k), which is about half of EPS, which is the lowest thermal conductivity of all insulation materials at present.

Rigid polyurethane has moisture-proof and waterproof properties. Rigid polyurethane has a closed cell ratio of over 90%, which is a hydrophobic material, and will not increase the thermal conductivity due to moisture absorption, and the wall will not penetrate water.

Rigid polyurethane is fire-resistant, flame-retardant and resistant to high temperatures. After adding flame retardant, polyurethane is a kind of flame-retardant self-extinguishing material. Its softening point can reach more than 250 degrees Celsius, and it decomposes only at higher temperatures. In addition, polyurethane foams when it burns. Ash is formed on the surface. This layer of ash helps insulate the foam underneath and can effectively prevent the fire from spreading. Moreover, polyurethane does not generate harmful gases at high temperatures.

| Production line shape size | 48000*8000mm | highest temperature | 70℃ |

| products specifications | Width:1200mm Thickness:15~100mm |

Minimun cut length | 1200mm |

| Production speed | 3-8 m/min | Diagonal accuracy | ±2mm |

| Weight | 40T | total power | 120kw |

PU sandwich panel production process methods There are basically two methods of PU sandwich panel production process, namely continuous production and discontinuous production.

Discontinuous PU sandwich panel production line is suitable for special shaped products that cannot be continuously produced, or the production volume is not enough to invest in continuous equipment. In the discontinuous process, the materials are processed separately, which means that after the surface material is formed, it is cut to the required length, and then assembled together into the laminator, and the foam is injected between the surface materials to generate a predetermined shape PU sandwich panel.

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Leading Manufacturer for Puf Panel Machine - CE Certificated PU Sandwich Panel Making Machine Line for Coldroom Wall Panel Production – Polyurethane, The product will supply to all over the world, such as: Leicester, Kenya, Lesotho, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

We have been looking for a professional and responsible supplier, and now we find it.