Leading Manufacturer for Puf Panel Machine - Factory Freezer Coldroom Panels Forming Machine PU Sandwich Panel Production Line – Polyurethane

Leading Manufacturer for Puf Panel Machine - Factory Freezer Coldroom Panels Forming Machine PU Sandwich Panel Production Line – Polyurethane Detail:

Factory Freezer Coldroom Panels Forming Machine PU Sandwich Panel Production Line

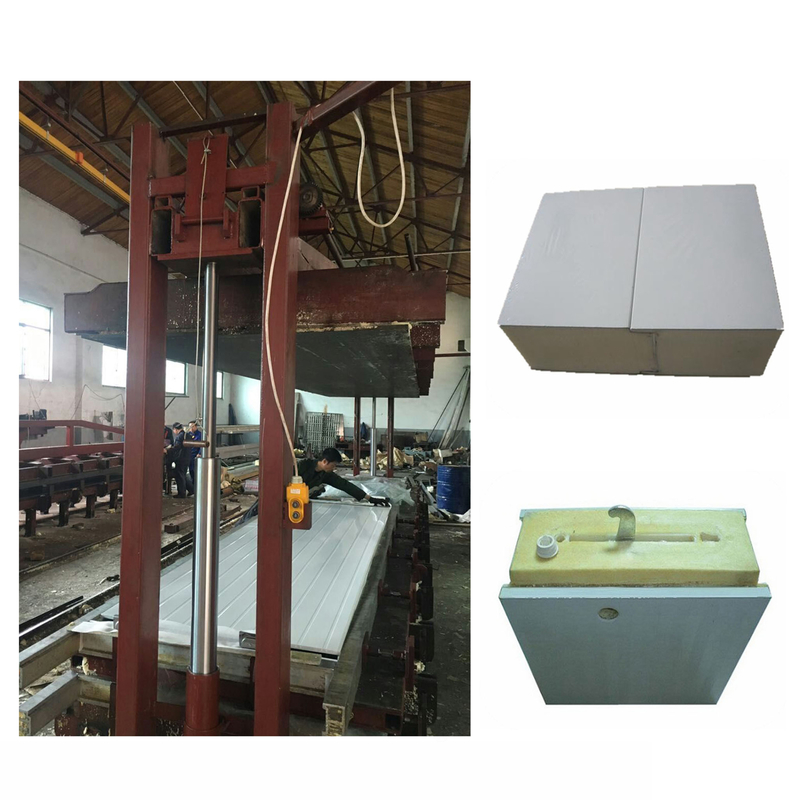

Introduciton: The two-in-two series plate production line designed and manufactured by our company is mainly used for the production of cold storage plates. The refrigerated plate production line has absorbed many advantages of the press. The composite machine is mainly composed of a machine to form a frame and a loading template. The clamping method is hydraulically driven. , The carrier template is heated by a water heating mold temperature machine to ensure a curing temperature of 40°. The laminating machine can be tilted from 0 to 5 degrees as a whole. In order to facilitate the work piece material and take action and move the template up and down automatically into the laminating machine; the four-layer mobile template can be alternately produced to improve production efficiency.

| Laminating machine parts | |||||

| number of plies | 2+2 | Load the template size | 12500*1200mm | ||

| mould height | 250mm | clamping force | 280kgf | ||

| working oil pressure | 15mpa | Heat the water pressure | 0.2mpa | ||

| water temperature | 85℃ | voltage | 380V/50HZ | ||

| power | 120kw | weight | 60T | ||

| Travelling form | |||||

| Upper mobile template operation level | 1052mm | lower speed of mobile template driven | 693mm | ||

| speed of mobile template driven | 360mm/s | ||||

| Track component | |||||

| orbit altitude | 170mm | Track length | 40500mm | ||

| Number of sets of orbit | 2sets | lay direction | Laminating machine around both ends | ||

This production line adopts European technology, cost reduced by technical transformation, which has high stiffness, strength, accuracy, and stability; polyurethane sandwich panel production line is used for the continuous production of polyurethane foam sandwich panel, such as polyurethane insulation panel with surface layer of non-woven cloth, cement mortar, kraft paper or aluminum foil.

Application: Cold storage is in thermal insulation materials,such as polyurethane insulation board,and create the suitable temperature by cooling facilities warehouse and low temperature conditions.

Application: Cold storage is in thermal insulation materials,such as polyurethane insulation board,and create the suitable temperature by cooling facilities warehouse and low temperature conditions.

Cold Room Panels are composed of 3 layers, the external and internal is galvanized sheet or Aluminum sheets, and core materials used high density polyurethane foam. Thanks to their good thermal insulation properties, it can be applied in projects that required very high heat insulation performanece, like cold storage, cool room ,freezer, refrigerating workshop construction.

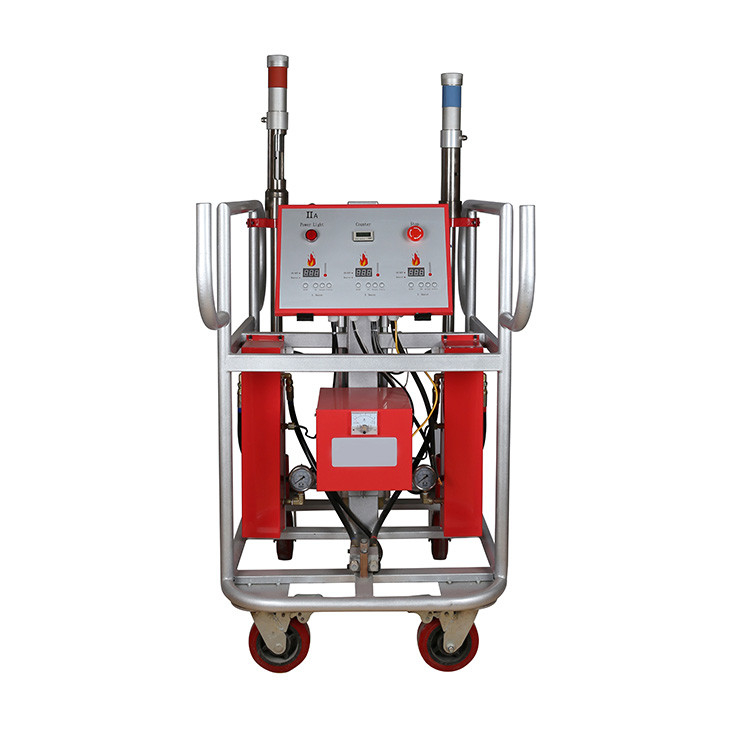

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Leading Manufacturer for Puf Panel Machine - Factory Freezer Coldroom Panels Forming Machine PU Sandwich Panel Production Line – Polyurethane, The product will supply to all over the world, such as: Nepal, Pakistan, Brazil, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!