OEM Customized Air Filter Manufacturing Machine - CE Low Pressure PU Foaming Machine , Pu Filling Machine – Polyurethane

OEM Customized Air Filter Manufacturing Machine - CE Low Pressure PU Foaming Machine , Pu Filling Machine – Polyurethane Detail:

| Product Name: | Pu Injection Moulding Machine | Injection Output: | 5-20g/s |

|---|---|---|---|

| Foam Application: | Photo, Mirror Frame | Input Power: | Three-phrase Five-wire,380V 50HZ |

| Rated Power: | About 8KW | Raw Material: | Rigid Foam Polyol+Isocyanate Wood Imitation |

| High Light: |

CE Low Pressure PU Foaming Machine, 8KW Low Pressure PU Foaming Machine, Low Pressure pu filling machine |

||

Wood Imitation Photo Mirror Frame Molding Machine For Decoration Low Pressure PU Foaming Machine Application of low pressure foaming machine: Polyurethane wood imitation is a high-density polyurethane rigid foam. It has a fine cell structure and has a much higher density than conventional thermal insulation polyurethane rigid foam. There are many applications of imitation wood materials, such as architectural imitation wood carving decorative strips, decorative panels Roman column carving paintings and other handicrafts, tables and chairs, industrial support cabinets, sofa legs, oil painting frames, mirror frames, doors, windows, flower pots, toilets Appliances, etc.

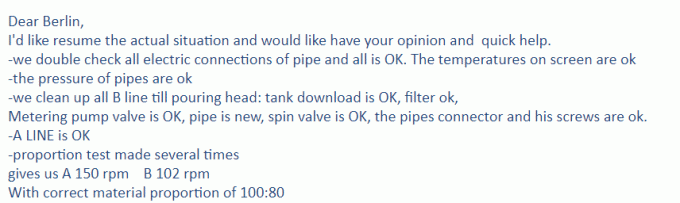

| No. | Item | Technical parameter |

| 1 | Foam application | Rigid foam |

| 2 | Raw material viscosity | Polyol~3000CPS ISO ~1000MPas |

| 3 | Injection output | 80~375g/s |

| 4 | Mixing ratio range | 100:50~150 |

| 5 | mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank volume | 120L |

| 7 | Metering pump | A pump: GPA3-25 Type B Pump: GPA3-25 Type |

| 8 | Compressed air needed | dry, oil free, P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

| 9 | Temperature control system | heat:2×3Kw |

| 10 | input power | three-phase five-wire 380V 50HZ |

| 12 | Rated power | About 12KW |

Features of pu injection machine: 1. For sandwich type material bucket, it has good heat preservation2. The adoption of PLC touch screen human-computer interface control panel makes the machine easy to use and the operating situation was absolutely clear.3. Head connected with the operation system, easy for operation4. The adoption of new type mixing head makes the mixing even, with the characteristic of low noise, sturdy and durable.5. Boom swing length according to the requirement, multi-angle rotation, easy and fast

6. High precision pump lead to measuring accurately

7. Easy for maintenance, operation and repair.

8. Low energy consumption.  Feedbacks:

Feedbacks:

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for OEM Customized Air Filter Manufacturing Machine - CE Low Pressure PU Foaming Machine , Pu Filling Machine – Polyurethane, The product will supply to all over the world, such as: Canada, Ukraine, Dominica, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly