professional factory for Shoe Making Machine - Polyurethane PU Shoe Insole Making Machine Shoe Injection Moulding Machine – Polyurethane

professional factory for Shoe Making Machine - Polyurethane PU Shoe Insole Making Machine Shoe Injection Moulding Machine – Polyurethane Detail:

| Product Name: | Fully Automatic Shoe Making Machine | Application: | Shoes / Sole / Insole / Shoes Pad |

|---|---|---|---|

| Material: | Polyol+Isocyanate | Output: | 100(kg/h) |

| High Light: |

Polyurethane insole making machine, PU insole making machine, Polyol Isocyanate sole Moulding Machine |

||

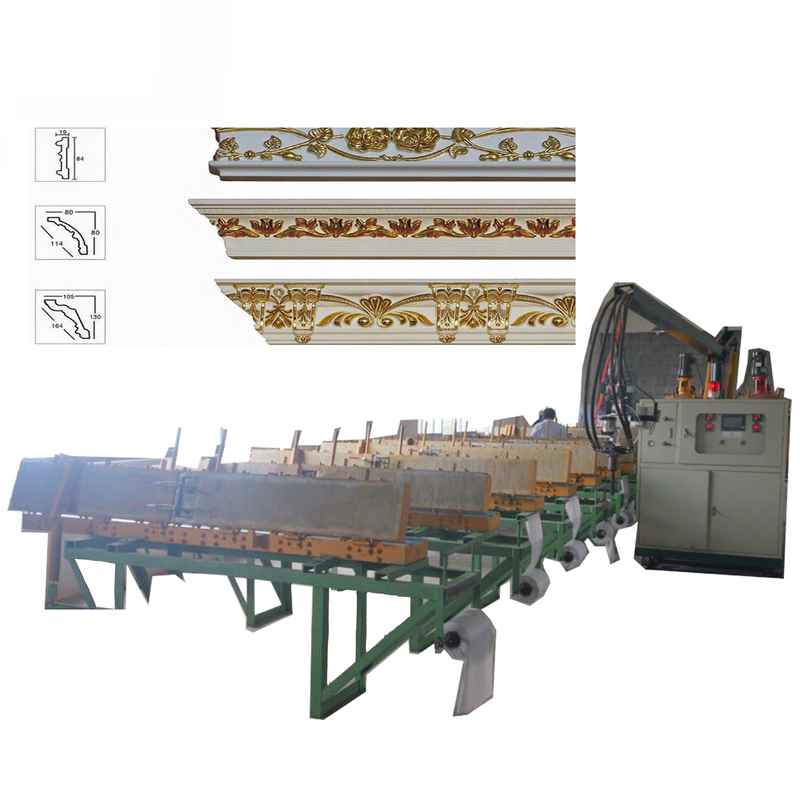

Polyurethane PU Shoe Insole Sole Making Machine Shoe Injection Moulding Machine Features of Shoe Moulding Machine: 1. Rugged mechanical structure, stable operation, silent design, long service life, and labor saving

Work operations.

2. Automatically open and close the mold base, high-strength mold clamping pressure, tightly closed, can effectively save the original

material.

3. The mold adopts water circulation heating method, and the aluminum template quickly conducts heat and saves energy.

4. According to the actual situation of the mold, develop a unique mold clamping mechanism and mold replacement

Simple and fast.

5. Adopt high-quality imported accessories, which are efficient and reliable. Polyurethane foaming machine:

| Model | Spit out | Volume of tank | The mixing ratio | Total power |

| SPU-R2A25 | 5-15g/s | 250L | 100:65-120 | 12KW |

| SPU-R2A26 | 30-150g/s | 250L | 100:65-120 | 12KW |

| SPU-R2A27 | 50-150g/s | 250L | 100:65-120 | 12KW |

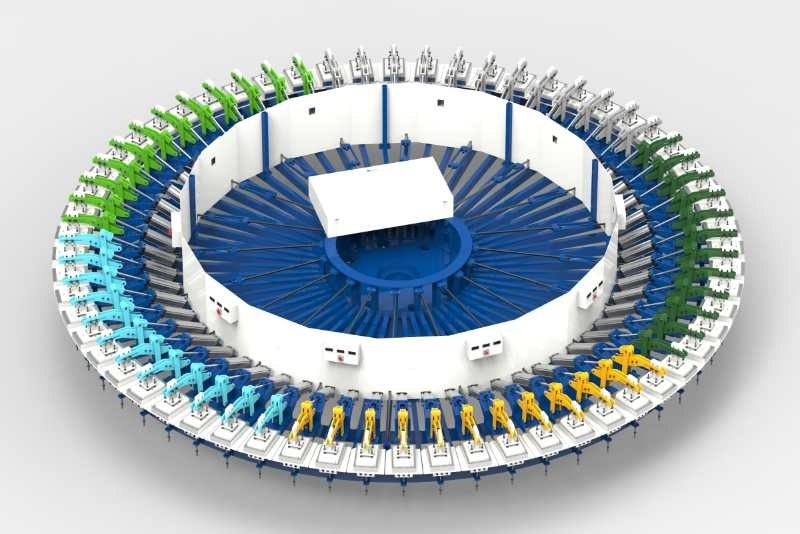

Disc production line:

| Model | Diameter size | Formwork station | Insulation size | Total power |

| SPU-605A | 7m | 80 station | 7*7*0.65m | 22kw |

| SPU-605B | 9m | 120 station | 9*9*0.65m | 22kw |

| SPU-605C | 11m | 160 station | 11*11*0.65m | 22kw |

Technical parameters of pu shoe production line:

1. Annular line length 19000, drive motor power 3 kw/GP, frequency control;

2. Station 60;

3. Oven length 14000, heating power 28kw, inner motor power 7 * 1.5 kw;

4. Mold opening and clamping adopt servo motor 1.5kw,, reducer PF – 115-32;

5. The panasonic PLC control, 10 inch touch screen;

6. Manufacturing process: injection mold release – hand set pieces – clamping – open die – casting mould – the – - cure – lock -molding – artificial pick-up – clean up moldHost equipment of pu shoe production line: Product component:

This equipment includes one pu foaming machine(can be low or high pressure foam machine) and one production line.It can be customized according to the products which the users need to produce. Main unit: Material injection by a precision needle valve, which is taper sealed, never worn, and never clogged; the mixing head produces complete material stirring; precise metering (K series precision metering pump control is exclsively adopted); single button operation for convenient operation; switching to a different density or color at any time; easy to maintain and operate. Control: Microcomputer PLC control; TIAN electrical components exclsively imported to achieve the goal for automatic, accurate and reliable control can be imputed with more than 500 working position data; pressure, temperature and rotation rate digital tracking and display and automatic control; abnormity or fault alarm devices. Imported frequency converter (PLC) can control the proportion of 8 different products. This is one set of molded pu foaming production line, it can produce different types of sponges products. Its sponges

products(high-resilient and viscoelastic) are mainly for high and medium level markets. For example, memory pillow, mattress, bus and car seat mat, bicycle and motorcycle seat mat, assembly chair, office chair, sofa and other one-time molded sponges. Application of pu shoe making machine:

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for professional factory for Shoe Making Machine - Polyurethane PU Shoe Insole Making Machine Shoe Injection Moulding Machine – Polyurethane, The product will supply to all over the world, such as: Amman, Niger, Rotterdam, We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.