professional factory for Spray Foam Transfer Pumps - Cyclopentane Coldroom Panel Pu Foam Injection Machine – Polyurethane

professional factory for Spray Foam Transfer Pumps - Cyclopentane Coldroom Panel Pu Foam Injection Machine – Polyurethane Detail:

| Name: | High Pressure Pu Foam Machine | Foaming Principle: | High Pressure Air Type |

|---|---|---|---|

| Mixing Ratio Range: | 1:5~5:1(adjustable) | Injection Output (mixing Ratio 1:1): | 110-540g/s |

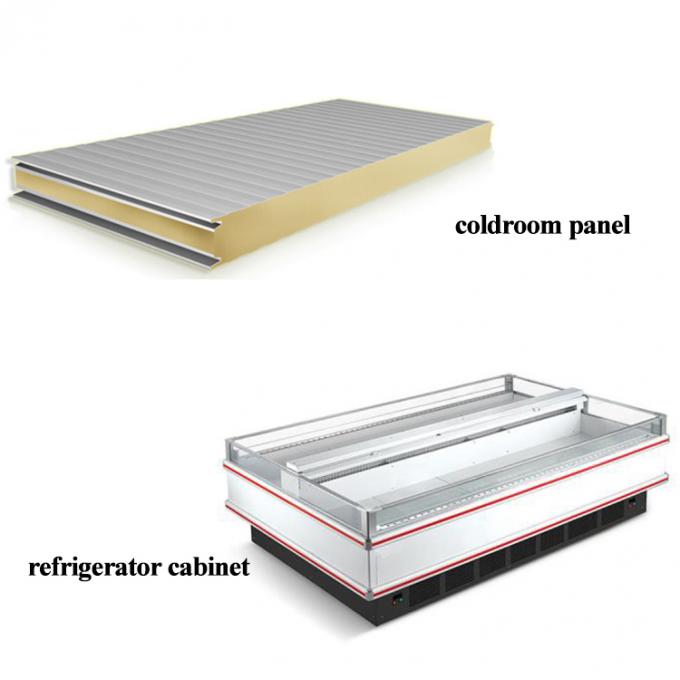

| Foam Type: | Rigid Foam | Applications: | Coldroom Panel, Refrigerator, Freezer |

| High Light: |

Coldroom Panel pu foam injection machine, Cyclopentane pu foam injection machine, Cyclopentane pu foam manufacturing machine |

||

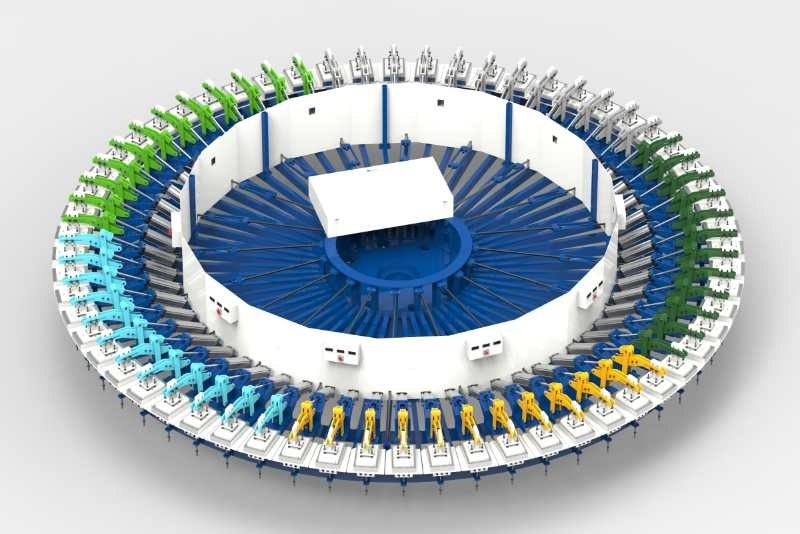

Cyclopentane PU Foam Injection Coldroom Panel Moulding Machine High Pressure PU Foaming Machine Introduction of Foam Rigid Foam Injection Machine: Polyurethane high-pressure machine can be used to make refrigerators, freezers, water heaters, disinfection cabinets, cold storage panels, etc. However, in recent years, the world's environmental protection requirements for products have become more and more stringent, and the manufacturing process of fluorine-free foam has emerged at the historic moment. The cyclopentane high-pressure machine is a machine that uses fluorine-free foaming technology for products such as freezers and cold storage panels. Specifications of High Pressure Foaming Machine:

| Technical Parameter: Injection output: 2-5000g/sMaterial tank volume: 30L-50OL Mixing ratio range: 100:28~48~150 Mixing head: 2800-5000rpm, forced dynamic mixing Compressed air needed: dry, oil free, P:0.6-0.8MPa Q:600NL/min(customer-owned) Nitrogen requirement: P:0.05MPa Q:600NL/min(customer-owned) Temperature control system: heat:2x3KW Input power: three-phase five-wire 380V 50HZ Other power customizable Total power: 35-70kw color( customizable): White/Red/Blueweight: 2000Kg-2500Kg Dimension: 4200(L)*2000(W)*2900(H)mm |

Equipment main technical characteristics: – With safety protection by anti riot glass and aluminum alloy arround the machine.

– There is a draining wind device on the safety cover;with safe wind exhaust system.

– Have wind pressure switch to ensure the good working of the fans.

– Cyclopentane gas detector is installed in the enclosure and connects with the control system.

– With explosion-proof pressure sensor for high and low pressure exchange system.

– Explosion-proof mixing motors for tank A & explosion-proof deceleration motor for metering pump.

– Pneumatic components also use explosion-proof type, and have good anti static and grounding measures.

– Automatic material feeding system is adopted with multi-point monitoring for the material level,avoid overflowing of raw material.

– Pneumatic controller for nitrogen gas at the mixing head. Application of polyurethane foam injection machine: CYCLOPENTANE high pressure foaming machine is widely used in home appliances refrigerators, freezers, water heater, disinfecting cabinet insulation, CFC-free foam of air conditioning sandwich panel.  Feedbacks of polyurethane injection molding machine

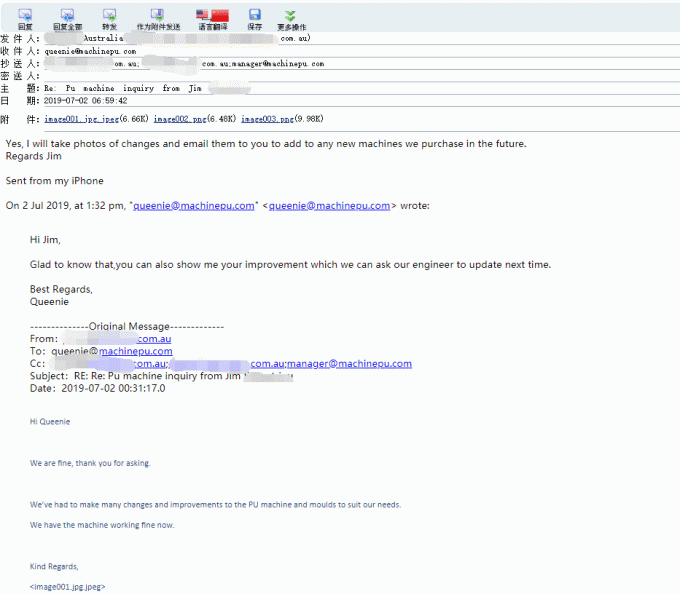

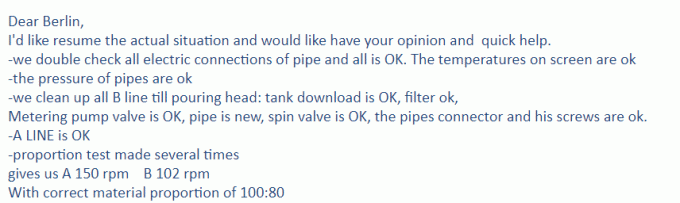

Feedbacks of polyurethane injection molding machine

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for professional factory for Spray Foam Transfer Pumps - Cyclopentane Coldroom Panel Pu Foam Injection Machine – Polyurethane, The product will supply to all over the world, such as: Bhutan, Mauritius, Venezuela, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!