Garage Door Making Machine Low Pressure Polyurethane Foam Machine For Shutter Door

Feature

Polyurethane low-pressure foaming machine is widely used in multi-mode continuous production of rigid and semi-rigid polyurethane products, such as: petrochemical equipment, directly buried pipelines, cold storage, water tanks, meters and other thermal insulation and sound insulation equipment craft products.

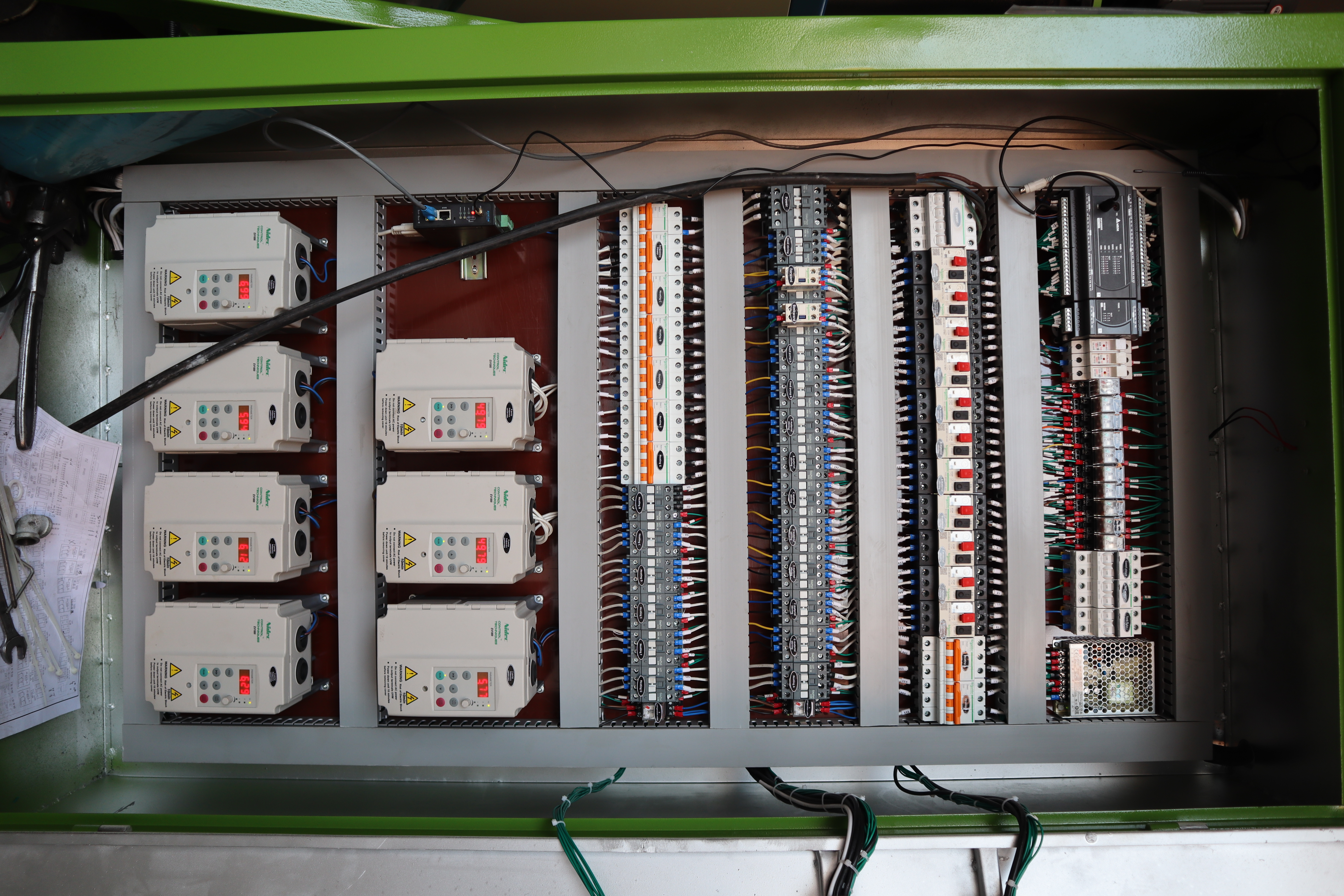

1.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors;

2.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

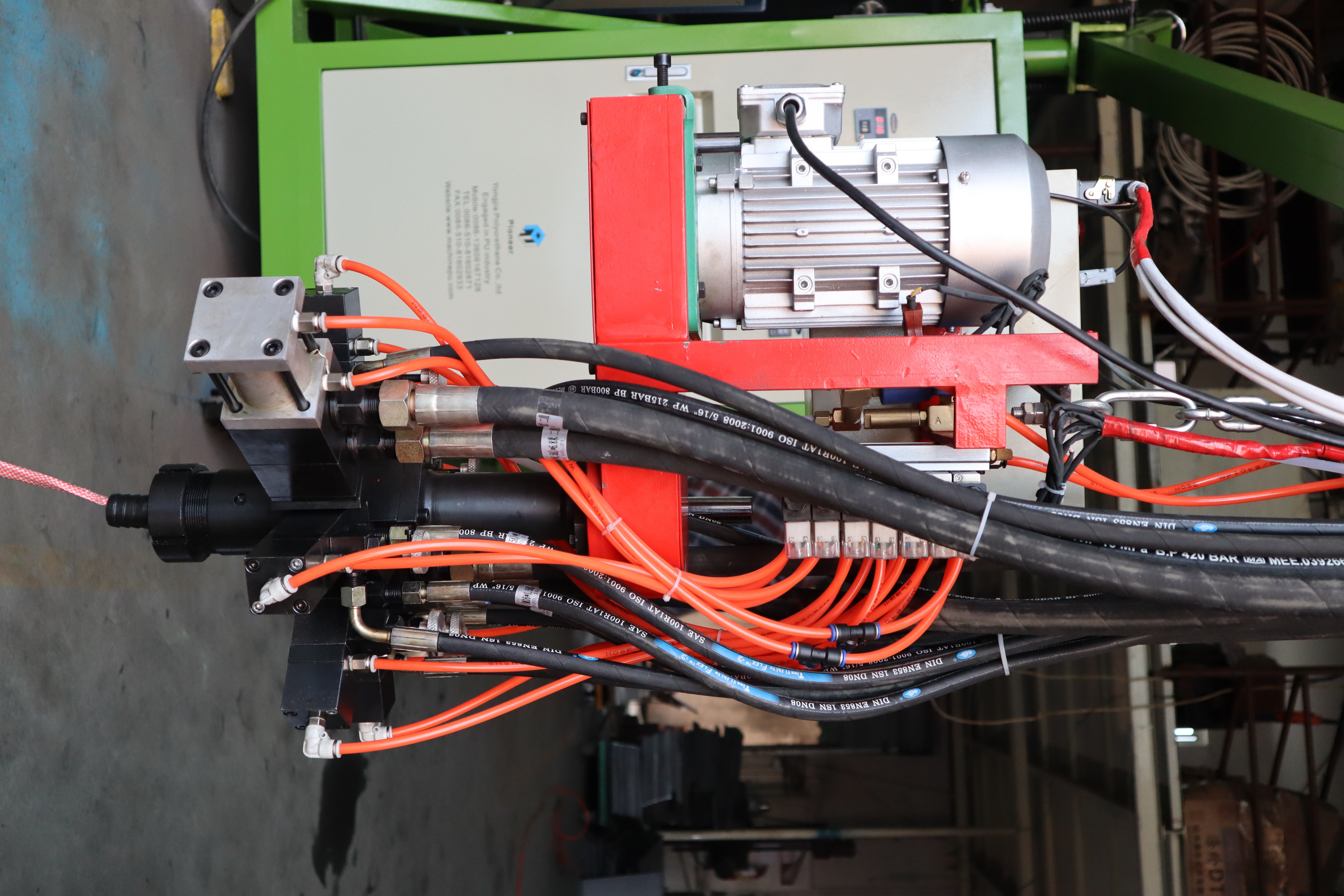

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

Detail

Material tank:

Double interlining heating material tank with insulation outer layer, heart rapidly, low energy consumption. Liner, upper and low head all use stainless 304 material, upper head is precision machinery sealing equipped to make sure the air tight agitation.

Mixing head:

Adopting floating mechanical seal device, high shearing spiral mixing head to make sure the even mixing within required adjusting range of casting mixing ratio. Motor speed is accelerated and frequency controlled through triangle belt so to realize the high speed rotation of mixing head in mixing chamber. Electrical control system: 1. Fully controlled by SCM (Single Chip Microcomputer).

2. Using PLC touch screen computer. Temperature,pressure, revolving speed display system.

3. Alarm function with acoustic warning.

Raw Material Formula Solution Support:

We have our own technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material formulas like polyurethane rigid foam, PU flexible foam, polyurethane integral skin foam and polyurea that meet all customer’ s requirements.

Specification

| Item | Technical parameter |

| Foam application | Rigid Foam Shutter Door |

| Raw material viscosity(22℃) | POL ~3000CPS ISO ~1000MPas |

| Injection flow rate | 6.2-25g/s |

| Mixing ratio range | 100:28~48 |

| Mixing head | 2800-5000rpm, forced dynamic mixing |

| Tank Volume | 120L |

| Input power | Three-phase five-wire 380V 50HZ |

| Rated power | About 11KW |

| Swing arm | Rotatable 90°swing arm, 2.3m (length customizable) |

| Volume | 4100(L)*1300(W)*2300(H)mm, swing arm included |

| Color( customizable) | Cream-colored/orange/deep sea blue |

| Weight | About 1000Kg |

Application