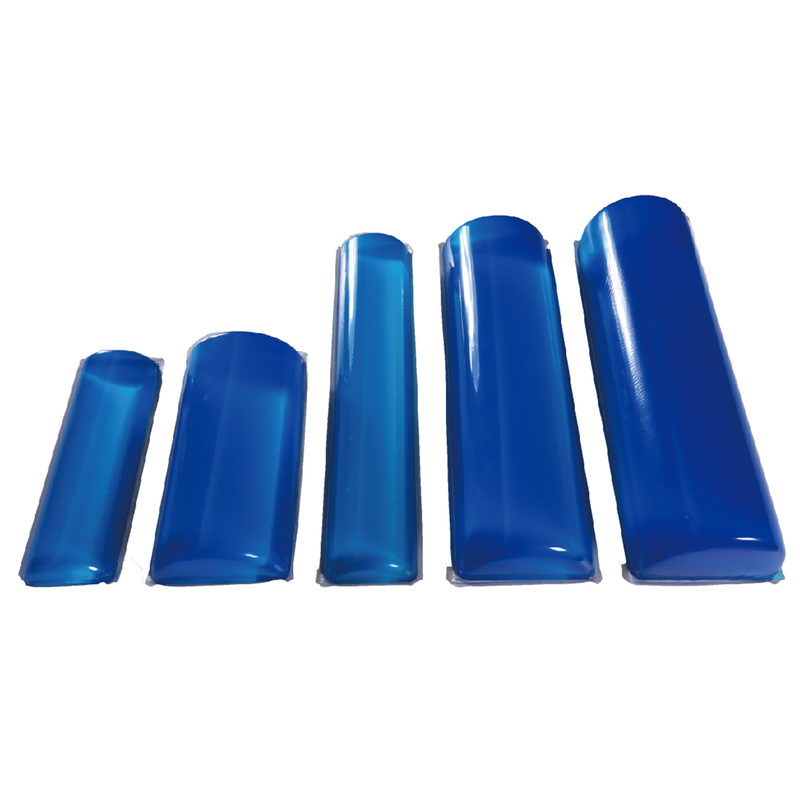

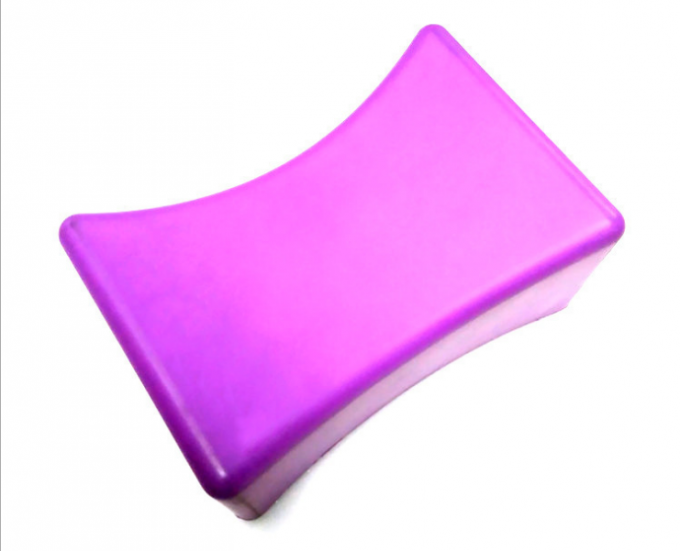

Custom Design PU Integral Skin Self Skinning Molded Foam Making Leg Supports

Custom Design PU Integral Skin Self Skinning Molded Foam Making Leg Supports

PU Polyurethane self-skinned Foam:

Integral skin foam, also commonly referred to as “self-skinning” foam, is a dual-layer structure formed through a material’s foaming process. This composition, similar to a loaf of bread, features a foam inner core surrounded by a solid outer crust or “skin”.

Integral skin foam offers a more high-density and thicker dense outer skin which is ideal for a number of applications including arm rests. The internal, underlying foam core is formulated with a lower density. Usually, Poly Labs integral skin foam has a density between 0.25 and 0.40 g/cm³. The hardness of the material can vary with formulation and density.

| Parameters Table | |

| Product Name | PU Polyurethane Integral Skin Foam Pad |

| Material | Polyurehtane |

| Color | Customized |

| Shape | Customize made |

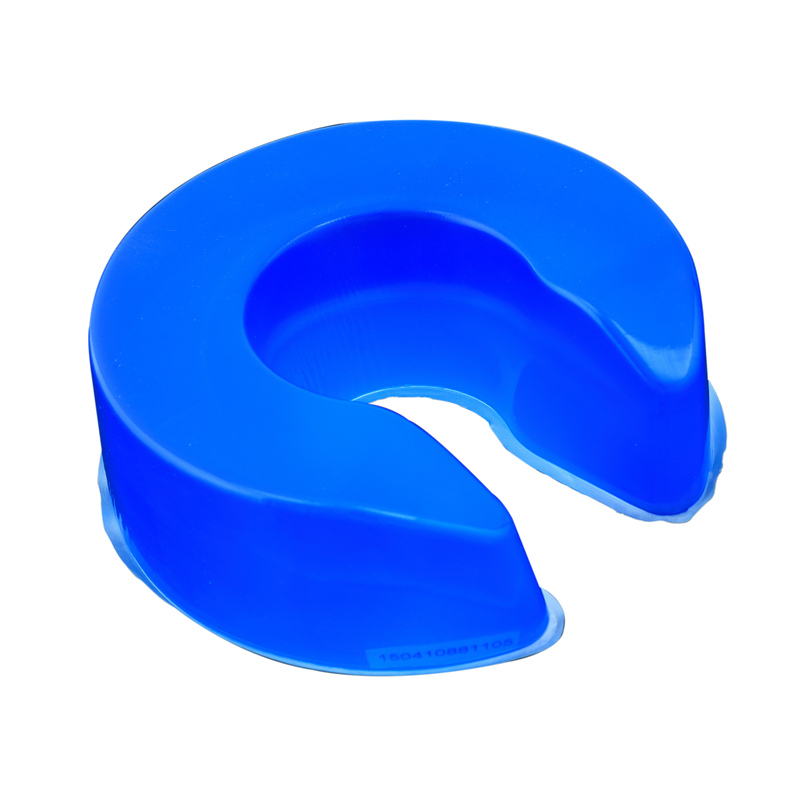

| Applications | Madical accessory |

PU Foam Integral Skin Advantage:

1. Extremely high impact resistance and wear resistance;2. Light weight and permanent elasticity;3. Hardness can be adjusted according to customer requirements;4. The surface is easy to color and easy to color as a whole;5. Any shape can be customized;

Application:

1. Automobile industry: automobile steering wheel, armrest, motorcycle seat cushion, door handle, spoiler, bumper, armrest cushion, automobile head cushion, shift lever, mudguard, overflow board, instrument panel, air filter , Bicycle cushions, tractors, off-road vehicle cushions, reaction injection molded products, etc .; 2. Sports equipment: fitness equipment cushions, backrests, kneeling cushions, grips, pedals, bicycle saddles, sports knee pads, etc .; 3. Medical equipment: integrated dental chair, edge banding of operating table, hanging rack, wheelchair armrest, etc .; 4. Household items: armrest pads, chair legs, decorative items;

Our Service:

From initial design to finished product, we offer:

Customized service with drawings or samples

A “one-stop shop” for all your seat projects

Engineering assistance throughout every development phase

Fully integrated manufacturing operation

Elaborate quality systems

Just-in-Time (including Just-in-Sequence)