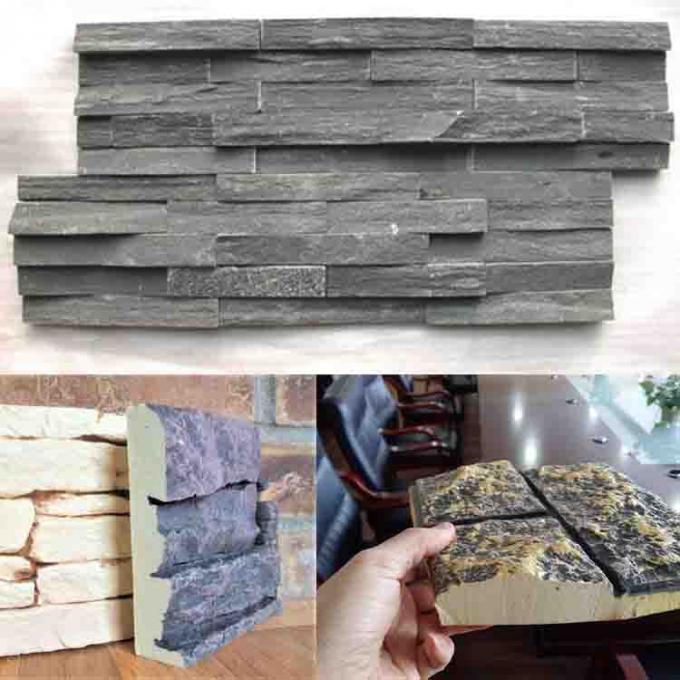

Wood Imitation Faux Stone Casting Pu Foam Making Machine

| Name: | Pu Foam Machine | Foaming Principle: | High Pressure Air Type |

|---|---|---|---|

| Mixing Ratio Range: | 1:5~5:1(adjustable) | Pouring Volume (g/s): | 270-1300g/s |

| Raw Material: | Rigid Foam | Applications: | Cultural Stone Decorative Panel |

| High Light: |

Faux Stone Pu Foam Making Machine, Wood Imitation Pu Foam Making Machine, 1300g/s high pressure foaming machine |

||

Wood Imitation Faux Stone Casting High Pressure PU Foaming Machine Description of pu foam machinery: High pressure PU foaming machine is one of our bestsellers, its main and key original parts are imported from Germany,Italy, and other countries. It has thecharacteristics of easy to operate, stable performance, energy saving and so on. Technical Parameter:

| Injection pressure | Injection flow | Mixing ratio range | Repeated injection precision | Mixing head | Rated power |

| 10~20Mpa (adjustable) | 270-1300g/s | 1:5~5:1(adjustable) | ±1% | 2800-5000 r/min | 15Kw |

Application of pu pouring machine: The PU cultural stone weighs about 3-4KG per square meter and is easy to install. Simple and lightweight, it is the product development concept of PU cultural stone and PU ancient brick; it can effectively reduce the cost of construction equipment required by traditional materials. It is light in weight and safe and effortless. The tools required for operation are light and easy to install, which is convenient for rapid construction. , Which can reduce the waiting time of users; the light weight of the material reduces the weight of the building and increases the seismic performance. Compared with building materials made of wall bricks and rock materials, PU cultural stone and PU ancient bricks with simple installation skills can highlight the advantages of quick and easy construction; reduce the dependence on experienced professional construction manpower, effectively save construction time and construction labor costs.

Product Features:

1.Material injection mixing head can freely move forward and backward, left and right, up and down;

2.Pressure needle valves of black and white materials locked after balanced to avoid pressure difference

3.Magnetic coupler adopts high-tech permanent magnet control, no leakage and temperature rising

4.Automatic gun cleaning after injection

5.Material injecting procedure provides 100 work stations, weight can be set directly to meet the production of multi-products

6.Mixing head adopts double proximity switch control, which can realize precise material injection.

7.Automatic switch from frequency converter soft start to high and low frequency, low-carbon , energy saving, environmental protection, greatly reduce the energy consumption

8.Full digital, modular integration control all process, accurate, safe, intuitive, intelligent and humanization Feedbacks of polyurethane injection molding machine: