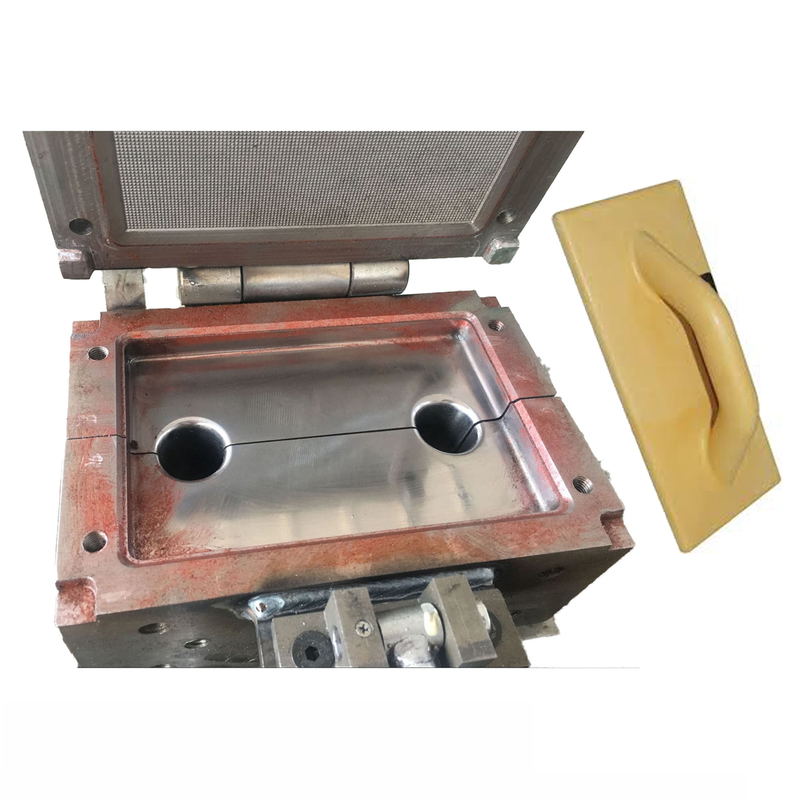

Polyurethane Foam Injection PU Shoe Sole Mould Making

Polyurethane Foam Injection PU Shoe Sole Mould Making

Over the years, the footwear industry has experimented with various materials to quest for the best sole material for shoes, sneakers and sandals. While a lot of these materials exhibited exceptional results in specific criteria, there was one material that stood out of the crowd when it comes to holistic performance – Polyurethane (PU).

Ever since its advent, the polyurethane has been gaining popularity amidst the footwear industry and has embarked upon a journey to become the best sole material in history. What has made polyurethane so famous is its extensive set of qualities that have allowed the PU sole suppliers to offer it as a suitable and trendiness sole material for various types of footwear.

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| Mold base | HASCO , DME , LKM , JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| Mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine |

| Month Production | 100 sets/month |

| Mold Packing | standard exporting Wooden case |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Certificate | ISO 9001:2008 |

| Lead time | 25~30 days |

We offer limitless options: static dissipating and anti-slip, color options, and more.We will manufacture an outsole, insole, midsole or custom footwear component specifically for your application. We will then formulate materials and polyurethane molds depending upon your desired mechanical properties (i.e. resistance, weight and durability). Contact us today to discuss your shoe-making and shoe-crafting needs.

Our professional one-stop plastic mould custom service:

1) Mould design service and Image design special for our customer

2) Plastic injection mold making,two shot injection mold,gas assisted mold

3) Precision plastic molding:two shot molding,precision plastic molding and gas assisted molding

4) Plastic Secondary operation,like Silk-screeking,UV,PU painting,Hot stamping,Laser engraving,Ultrasonic welding,Plating etc.

Application: