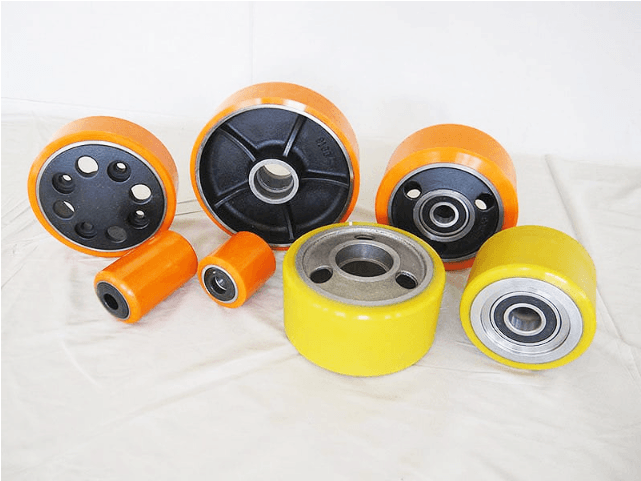

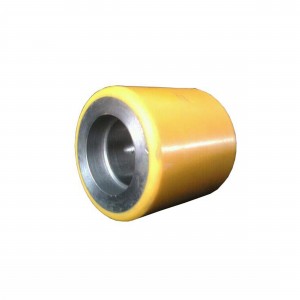

Polyurethane Forklift Wheel Truck Load-bearing Wheel PU Wheel Electric Forklift Drive Wheel

Feature

1. The physical properties of polyurethane can be flexibly changed within a certain range through the selection of raw materials and the adjustment of formula, so as to meet the unique requirements of users for the performance of rubber-coated wheels. Many users have special requirements for an important index of the product, such as hardness. Polyurethane elastomer can be processed into soft paper pulleys around Shore A40, and can be processed into hard load wheels above Shore D80. What materials are difficult to achieve, polyurethane rubber-coated wheels can meet the needs of different users.

2. Good wear resistance.

In the presence of wetting media such as water or oil, the wear resistance of polyurethane fork wheels is several to ten times that of ordinary rubber materials. Although other materials are very hard, they are not elastic and not necessarily wear-resistant. Polyurethane still maintains a certain elasticity in the case of high hardness, which also determines that it has outstanding buffering and wear-resistant properties, such as rice hulling rollers. Using other hard materials will first damage the grain and not wear-resistant, and the polyurethane-coated roller will not damage the grain and wear-resistant. Elevator wheels and roller skate wheels, etc. are also used polyurethane elastomers.

3. The processing is diverse, and the scope of application is wide.

Polyurethane fork wheel elastomer is cast-molded or sprayed, potted, and centrifugally molded (referring to pouring or CPU); it can also be made into pellets, which, like ordinary plastics, can be molded by injection, extrusion, calendering, blow molding and other processes ( Refers to TPU or extrusion). Molded or injection-molded parts can also be machined such as cutting, grinding, and drilling within a certain hardness range. The diversity of processing makes the applicability of polyurethane elastomers very wide, and the application fields continue to expand.

4. Oil resistance, hydrolysis resistance, ozone resistance, aging resistance, radiation resistance, low temperature resistance, good sound permeability and strong bonding ability. These advantages are the reason why polyurethane fork wheel elastomers are widely used in military, aerospace, logistics, automation and other fields.

Detail

1. Cost-effective, lightweight and easy to install

2. The surface is treated with baking paint to ensure that the appearance is not easy to change color, not easy to rust, so that you can buy it with confidence and use it comfortably

3. Thickened material, using aluminum alloy material and special technology, has good wear resistance and impact toughness

4. High protection level, long service life and low noise