Polyurethane Seal Strip 4.5KW PU Gasket Dispensing Machine

| Processing Type: | Foaming Machine, Foaming Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net | Voltage: | 380V |

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| Applicable Industries: | Manufacturing Plant | Product Name: | Seal Strip Making Machine |

| Strength 1: | Self-cleaning Filter | Strength 2: | Precise Metering |

| Feeding System: | Automatic Feeding System | Control System: | PLC Control System |

| Foam Type: | Flexible Foam/ Rigid Foam | Output: | 16-66g/s |

| Tank Volume: | 120L | Power: | Three-phase Five-wire 380V |

| Power: | About 9 KW | Weight: | About 2000kg |

| Port: | Ningbo For Sael Strip Making Machine | ||

| High Light: |

Continuous urethane dispensing machine, 66g/s PU Gasket Dispensing Machine, 4.5KW PU Gasket Dispensing Machine |

||

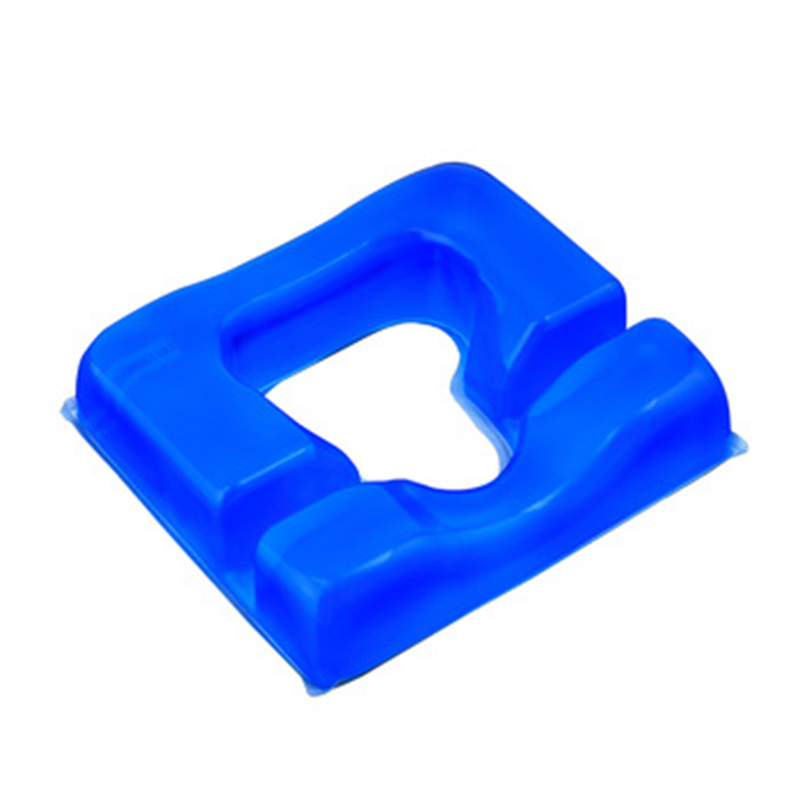

Polyurethane Seal Strip PU Dispensing Machine For Foam Seal Introduction Of Coated Polyurethane Foam Seal Casting Machine: The casting machine is used in production line of cladding type sealing strip to produce different kinds of cladding type foam weatherstrip.

| Flow | Tank | Proportion | Production Mode | Metering Pump | Total Power |

| 2-10 g/s | 30 L | 100:25-40 | Continuous | A.JR2.4/ B.JR1.2 | 4.5 KW |

Product Features:

1. High precision metering pump, accurate metering, random error within ± 0.5%;

2. High Performance anti drooling mixing device with flowback adjusting function, accurate material output synchronization and even mix;

3. Fully automatic control of material injecting time, cleaning frequency, automatic cleaning flush and air purge;

4. Adopting PLC, touch screen man-machine interface, and servosystem to control casting, move as per preset track, accurate positioning;

5. Additional functions optional: remote control, automatic feeding, high viscosity filling pump, automatic cycle during shutdown, mixing head water flush,etc.

Two mixing hands:

High-performance mixing device, precise synchronizing of raw material discharge, uniform mixing; new sealing structure, reserved cold water circulation interface to ensure long-term continuous production is not blocked

Material Tank:

30L autotemperature control three layer stainess steel material tank, automatic stirring with alarm for lack of material

Metering Pump:

The higher precision metering pump is equipped with more accurate, the measurement accuracy error does not exceed ±0.5%; the variable frequency motor is matched with the frequency conversion to adjust the flow rate and pressure of the raw material, the precision is high, and the proportional adjustment is simple and quick. Application: Cladding type sealing strip is composited by four fine quality materials, outer wrapped with PE film, it is good partner of modern household doors and windows with elegant appearance. Features: 1. Cladding type weatherseal has more excellent test results than other traditional products in ageing resistance, fatigue resistance, compression deformation test, compression test, thermal conductivity k value test, water invasion, and water permeability. 2. Coated weatherstrip is energy saving and environmental protecting, soundproof and noise reducing, uvioresistant, non-toxic, do not react with any paint or detergent, which meets the needs of green health topics.`  Packing & Delivery:

Packing & Delivery:

| Packaging | |

| Size | 4100*1250*2300(mm) |

| Weight | 1.2 T |

| Packaging Details | The normal package is wooden box(Size: 2600*1500*2600). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Why Choose Us:  Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Service:

1. Professional and patient consulting service to help you find the suitable solution.

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4. Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5. Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7. For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8. We give an accessory box for free.

9. We offer development solutions for raw material formulations.

10. If you need to visit the factory, we will arrange for personnel to pick up the airport. FAQ: 1. Are you factory or trading company?

We are professional factory in PU industry with more than 10 years experience, covering high pressure pouring machine,low pressure foaming machine, pu spraying foam machine,pu elastomer casting machine and production line.

2. Where is your factory ?

Our Factory is located in Wuxi city, Jiangsu Province.

3. How can I get your factory?

By air: You can take a plan to WUXI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

4. Do you provide pick-up service?

Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.

5. What is the PU raw material used with this polyurethane/polyurea foam casting machine?

Polyurethane which has two components polyol and isocyanate(poly and iso/mdi). Polyurea also can be used which helps to waterproofing and Anticorrosion and rust prevention. Polyurethane can be divided into two kinds, flexible foam and rigid foam. And flexible foam or rigid foam also has two kinds, open cell foam and closed cell foam.

6. If I need to develop a special PU raw material formula solution based on my product, can you provide it?

Yes, we can. We have technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material soluation like polyurethane rigid foam, polyurethane flexible foam, polyurethane integral skin foam and polyurea to meet customer' s requirements.