10L/Min Standing Polyurethane Anti Fatigue Mats Polyurethane Foam Machine

| Name: | High Pressure Pu Foam Machine | Foaming Principle: | High Pressure Air Type |

|---|---|---|---|

| Mixing Ratio Range: | 1:5~5:1(adjustable) | Injection Output (mixing Ratio 1:1): | 110-540g/s |

| Foam Type: | Soft Foam | Applications: | Anti Fatigue Mats |

| High Light: |

Full digital polyurethane foam machine, 10L/min polyurethane foam machine, 10L/min polyurethane foam equipment |

||

Standing Soft Polyurethane Foam Anti Fatigue Mats Making Machine High Pressure PU Foaming Machine Equipment main technical characteristics: 1. Material injection mixing head can freely move forward and backward, left and right, up and down;2. Pressure needle valves of black and white materials locked after balanced to avoid pressure difference

3. Magnetic coupler adopts high-tech permanent magnet control, no leakage and temperature rising

4. Automatic gun cleaning after injection

5. Material injecting procedure provides 100 work stations, weight can be set directly to meet the production of multi-products

6. Mixing head adopts double proximity switch control, which can realize precise material injection.

7. Automatic switch from frequency converter soft start to high and low frequency, low-carbon , energy saving, environmental protection, greatly reduce the energy consumption

8. Full digital, modular integration control all process, accurate, safe, intuitive, intelligent and humanization Technical Parameter:

| No. | Item | Technical Parameter |

| 1 | Foam application | PU(Polyurethane) |

| 2 | Raw material viscosity(22℃) | POL~2500mPas ISO ~1000mPas |

| 3 | Injection pressure | 10~20Mpa (adjustable) |

| 4 | Injection Output (mixing ratio 1:1) | 70-350g/s |

| 5 | Mixing ratio range | 1:3~3:1(adjustable) |

| 6 | njection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature control error | ±2℃ |

| 8 | Repeated injection accuracy | ±1% |

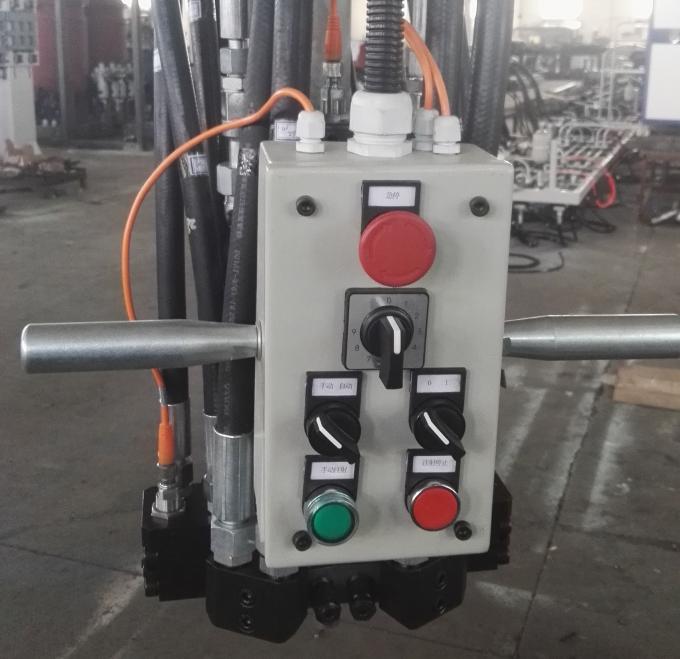

| 9 | Mixing head | Homemade, four oil hoses, double oil cylinders |

| 10 | Hydraulic system | Output 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 280L |

| 12 | POL metering pump | Guoyou A2VK-12 |

| 13 | ISO metering pump | Guoyou A2VK-06 |

| 1 | Compressed air required | Dry, oil free P: 0.7Mpa Q: 600NL/min Prepare by Customer |

| 15 | Temperature control system | 5HP |

| 16 | Input power | Three-phase five-wire,380V 50HZ |

Details of Floor Mat Molding Machine: High and low pressure switching unit: High/low pressure cyclical switch unit control the high/low cyclical switch of the two components, to enable components to form low energy circle and extend machine’s service life. The equipment has 4 sets of high and low pressure switching unit for sharing. Self-cleaning filter: Scraper type self-cleaning filter which consists of stator, rotor, scraper, keeps materials unblocked and filtered out in the loop. The hand wheel should be rotated on a regular basis, and dirt discharged through ball valve at the bottom. Mixing head: Adopting self-cleaning L type mixing head, adjustable needle type nozzle, V-shape spraying orifice, high pressure collision mixing principle, which ensure are fully mixing of components.  Application of polyurethane foam injection machine: Anti-fatigue mat reduces fatigue when standing, perfect for kitchens or standing desks

Application of polyurethane foam injection machine: Anti-fatigue mat reduces fatigue when standing, perfect for kitchens or standing desks

Cushiony foam layer conforms to the contours of your feet

Stain- and abrasion-resistant surface; easy to clean

Non-curling edges so you won't trip. Non-slip base so the mat stays in one place  Feedbacks of polyurethane injection molding machine

Feedbacks of polyurethane injection molding machine