Multipurpose Ball 120L High Pressure PU Foaming Machine

| Processing Type: | Foaming Machine, Foaming Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net | Voltage: | 380V |

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| Applicable Industries: | Manufacturing Plant | Strength 1: | Self-cleaning Filter |

| Strength 2: | Automatic Feeding System | Strength 3: | PLC Control System |

| Strength 4: | Precise Metering | Foam Type: | Flexible Foam |

| Output: | 16-66g/s | Tank Volume: | 120L |

| Power: | Three-phase Five-wire 380V | Name: | Polyurethane Machine |

| Power: | About 9 KW | Weight: | About 1000kg |

| Port: | Ningbo For Polyurethane Foam Machine | ||

| High Light: |

120L High Pressure PU Foaming Machine, 120L pu foam making machine, SS304 High Pressure PU Foaming Machine |

||

PU Injection Foaming High Pressure Machine For Polyurethane Ball Product Description: Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine.

Product Description: Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyurethane and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

| No. | Item | Technical parameter |

| 1 | Foam application | Flexible Foam |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPasISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 10~50g/min |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 500L |

| 15 | Temperature control system | Heat: 2×9Kw |

| 16 | Input power | Three-phase five-wire 380V |

Product Features of High Pressure PU Machine:

1.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3.Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

Raw Material Formula Solution Support:

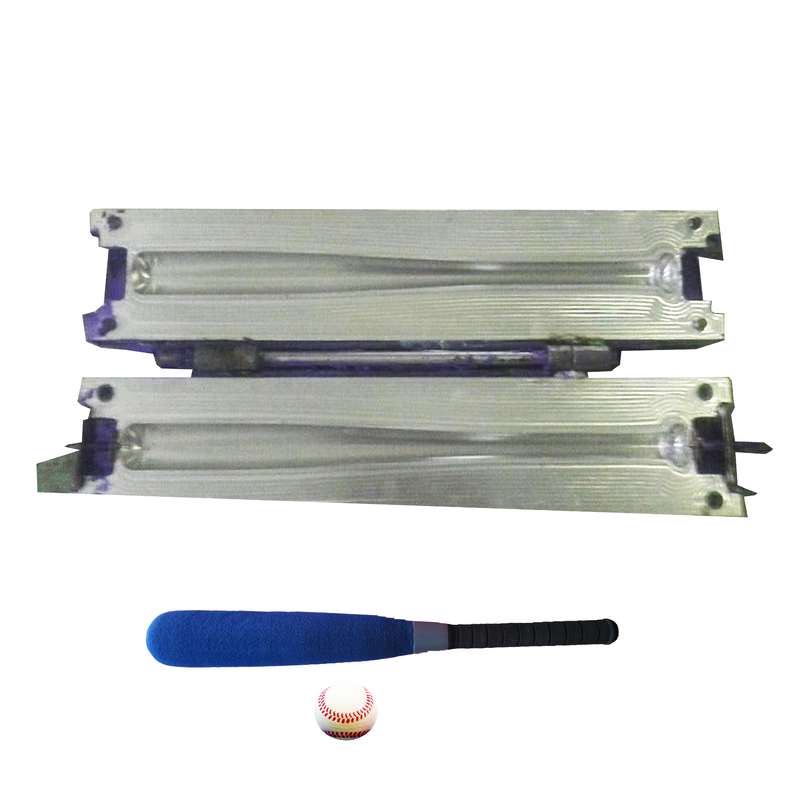

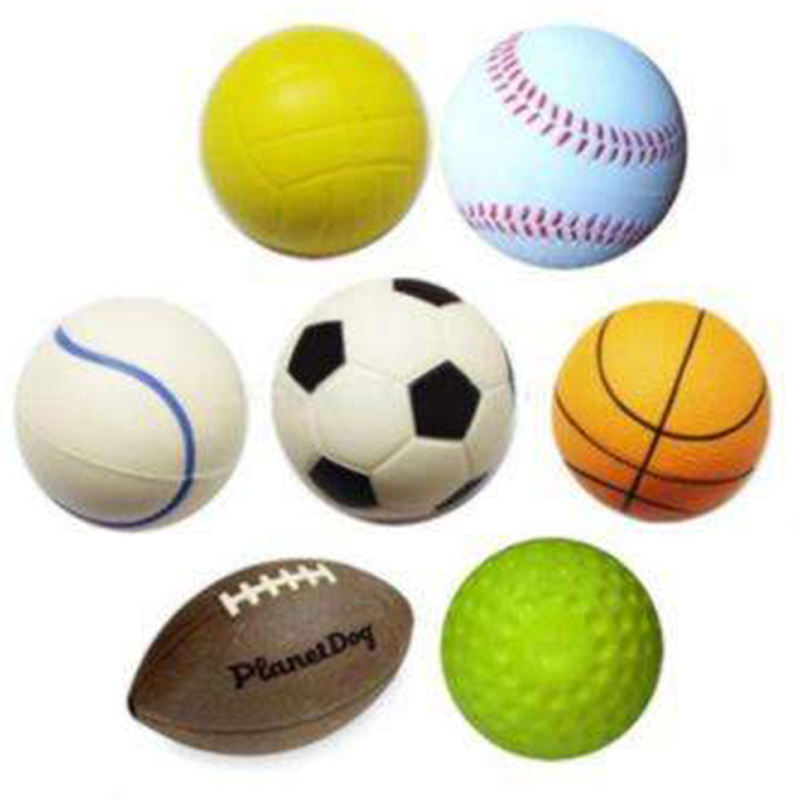

We have our own technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material formulas like polyurethane rigid foam, PU flexible foam, polyurethane integral skin foam and polyurea that meet all customer’ s requirements. Application: For those who don’t know, stress balls are little foam toys that are most commonly found in office settings. They are meant to be squeezed when you’re dealing with a lot of frustration, like driving in rush hour traffic, struggling to meet a deadline, or working with someone who always takes the last Snickers from the vending machine.Stress balls come in many different shapes, all depending on your industry or personality. For example, a little league team might like advertising with baseball stress balls, but that same shape wouldn’t really make sense for the cable guy. It all depends on who you are and what message you’re trying to get out there! PU polyurethane high pressure machine is also suitable for the production of polyurethane pillow, steering wheel, bumper, self skin, high reilience, slow rebound, toys, fitness equipment, insulation layer, bicycle cushion, rigid foam, cold storage panel, medical equipment, elastomer, shoe sole, ect…

PU polyurethane high pressure machine is also suitable for the production of polyurethane pillow, steering wheel, bumper, self skin, high reilience, slow rebound, toys, fitness equipment, insulation layer, bicycle cushion, rigid foam, cold storage panel, medical equipment, elastomer, shoe sole, ect… Our Factory Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company’s products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Factory Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company’s products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Service

1. Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3.Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8.We give an accessory box for free.

9.We offer development solutions for raw material formulations.

10.If you need to visit the factory, we will arrange for personnel to pick up the airport.