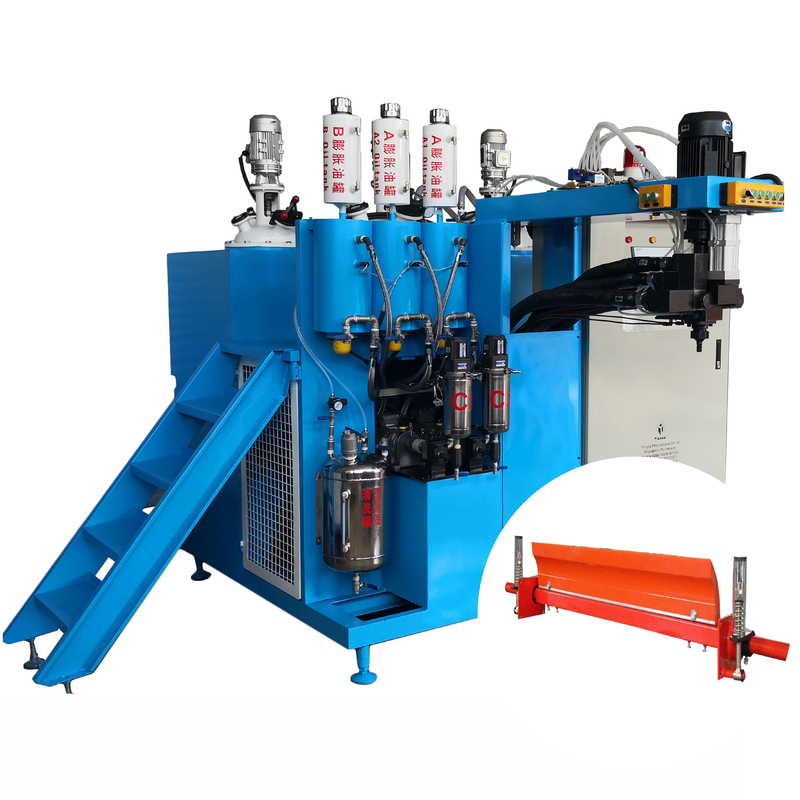

PU Roller Making Polyurethane Elastomer Casting Machine

| Key Words: | Polyurethane Casting Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net | Machine Type: | Foaming Machine |

| Voltage: | 380V | Dimension(L*W*H): | 2300*2000*2300 Mm |

| Power (kW): | 25~31KW | Weight (KG): | 2000 KG |

| Warranty: | 1YEAR | Key Selling Points: | Automation |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Local Service Location: | Pakistan, India |

| Showroom Location: | Turkey, Pakistan, India | Applicable Industries: | Manufacturing Plant, Construction Works |

| Mix Head: | Mix Evenly, No Bubble | Injection Pressure: | 0.01-0.1Mpa |

| Injection Time: | 0.5~99.99S (correct To 0.01S) | Temperature Control: | ±2℃ |

| Repeated Injection Accuracy: | ±1% | Color: | Deep Blue/cream Color/red |

| Ratio Between A And B: | 1 : 1 | Raw Material: | Polyol And Isocyanate |

| Port: | Ningbo | ||

| High Light: |

50HZ PU casting machine, polyurethane elastomer casting machine, YONGJIA elastomer casting machine |

||

Polyurethane Elastomer Pouring Machine For PU Roller Making PU Elastomer Casting Machine Introduction:Polyurethane elastomer casting machine is used to produce MOCA or BDO as chain extender of castable polyurethane elastomer. PU elastomer casting machine is suitable for manufacturing all kinds of CPU, such as seals, grinding wheel, roller, screen, impeller, OA machine, pulley, buffer and other products.

| No. | Item | Technical Parameter |

| 1 | Injection Pressure | 0.1-0.6Mpa |

| 2 | Injection flow rate | 50-130g/s 3-8Kg/min |

| 3 | Mixing ratio range | 100:6-18(adjustable) |

| 4 | Injection time | 0.5~99.99S (correct to 0.01S) |

| 5 | Temperature control error | ±2℃ |

| 6 | Repeated injection precision | ±1% |

| 7 | Mixing head | Around 5000rpm (4600~6200rpm,adjustable), forced dynamic mixing |

| 8 | Tank volume | 220L/30L |

| A maximum working temperature | 70~110℃ | |

| B maximum working temperature | 110~130℃ | |

| 9 | Cleaning tank | 20L 304# stainless steel |

| 10 | Metering pump | JR50/JR50/JR9 |

| A1 A2 Metering pump displacement | 50CC/r | |

| B Metering pump displacement | 6CC/r | |

| A1-A2-B-C1-C2 PUMPS MAXIMUM SPEED | 150RPM | |

| A1 A2 agitator speed | 23RPM | |

| 11 | Compressed air requirement | Dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

| 12 | Vacuum requirement | P:6X10-2Pa(6 BAR) Speed of exhaust:15L/S |

| 13 | Temperature control system | Heating: 18~24KW |

| 14 | Input power | Three-phrase five-wire,380V 50HZ |

| 15 | Heating power | TANK A1/A2: 4.6KW TANK B: 7.2KW |

| 16 | Total power | 34KW |

| 17 | Working Temperature | Room temperature to 200℃ |

| 18 | Swing arm | Fixed arm, 1 meter |

| 19 | Volume | About 2300*2000*2300(mm) |

| 20 | Color (selectable) | Deep blue |

| 21 | Weight | 2000Kg |

Product Features of PU Elastomer Casting Machine:

High temperature low speed high precision metering pump, metering accuracy, random error within ±0.5%. Material output is regulated by frequency converter and frequency conversion motor, high pressure, high precision, simple and fast speed ratio control. High performance mixing device, adjustable pressure, accurate material output synchronization, uniform mixing; The new mechanical seal structure eliminates backflow problems. High efficient vacuum device, special stirring head, to ensure no bubbles. Electromagnetic heating method for heat conduction oil, high efficiency and energy saving; Multipoint temperature. The control system ensures temperature stability with a random error of <±2°C. PLC and touch screen man-machine interface are adopted to control pouring, automatic cleaning and air purging. The stability of the

The performance has strong operability, which can automatically identify, diagnose and alarm abnormal conditions, and display abnormal factors.

Applications:

Widely used in the production of CUP type PU elastomer items which adopt MOCA or BDO as chain extender,such as CPU wheel,castor,roller,sieve plate,impeller,seal ring,shock absorber,dumbell and so on.

Widely used in the production of CUP type PU elastomer items which adopt MOCA or BDO as chain extender,such as CPU wheel,castor,roller,sieve plate,impeller,seal ring,shock absorber,dumbell and so on.

Our team:

We have professional mechanical engineers, chemical engineers, process engineers and other teams, they have more than 10 years of experience in the field of polyurethane foam. In addition, we have a dedicated sales team, who are young but diligent and experienced. We can meet your requirements for PU foaming products, PU moulds and PU foaming machines.

Our services:

1. Professional patient consultation services to help you find the right solution.

2. Further negotiate technical details, machine configuration, price basis, payment terms and delivery time.

3. Strong control of machine production schedule and quality, and timely release detailed information to you.

4. Free training in our factory during machine inspection. Or photos and videos of machines and packaging for your confirmation before shipment.

5. Ship quickly and safely according to your requirements, including booking, container loading and shipping documents.

6. For technical support, we can help you online by email and phone, or if necessary, we can send technicians to your website.

7. For spare parts, we will provide spare parts free of charge within the one-year warranty period and at the original price after the warranty period.

8. We give away an accessory box for free.

9. We provide raw material formulation development solutions.

If you need to visit the factory, we will arrange someone to pick you up at the airport.